Vol.9 PARTS NAME OF STANDARD TOOLING

Turret punch press Tool is composed of several parts.

Also, the style of the tool varies depending on the machine to be used. This time, we summarized the part name and functions.

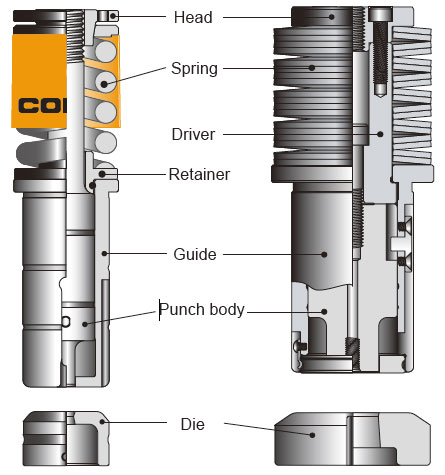

Thick Turret tooling

The thick turret tooling receives the pressing force of the press striker with the head, transmits the force to the punch body, and punches the workpiece with the punch edge and the die.

Also, after processing, the workpiece is held by the guide and stripper by the force of the spring, and the punch edge is pulled out.

EACH PART NAME AND FUNCTION OF TOOL

1. PUNCH BODY, DIE

It punched out workpiece at punch and die.

2. STRIPPER

A part that holds the workpiece during processing.

After processing, the punch edge is pulled out from the workpiece at this part. (This is called a strip.)

3. GUIDE

Insert this part into the turret and hold and guide the punch body.

4. HEAD

Part that receives the force of the striker directly and conveys it to the driver and the punch body.

In case of the small diameter tool, rotate it to adjust the punch length.

5. SPRING

Hold the workpiece during processing and pull the punch edge away from the work after processing.

Use coil spring, urethane spring, disc spring and so on.

6. DRIVER

The part to attach the punch body. Also, add a shim between the driver and the punch and adjust the punch length.

In the case of Protech Ⅲ, adjustment is possible without shims.

7. RETAINER

Guide would be attached in this part. It also serves to hold the spring.

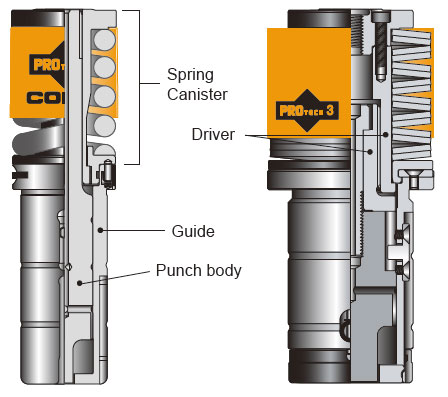

8. SPRING CANISTER

A combination of head, spring and retainer collar.

It is possible to adjust the length of the tool without tools.

〔 TOOLING STRUCTURE (Ex. LONG TYPE) 〕

〔 TOOLING STRUCTURE (EX. PROTECH 3) 〕

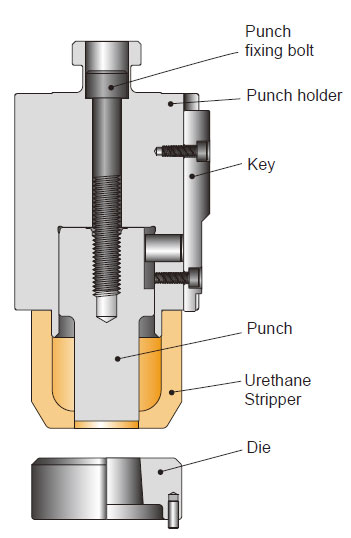

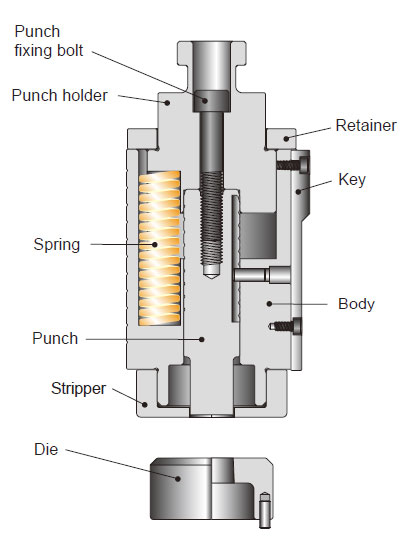

MURATA TYPE TOOLING

The Murata type toolings transmits the pressing force of the press ram to the mechanically connected holder / punch body and punches out the workpiece with the punch edge and the die.

Also, after processing, the ram will forcibly pull up the holder.

Two types of Holders are as follows.

| 1. 114 Type (Urethane stripper type) | ・・・ | Low cost and simple structure. |

| 2. Vulcan Type (Metal stripper type) | ・・・ | Designed for Strengthened stripping power compared to standard 114 Type. |

EACH PART NAME AND FUNCTION OF TOOL

〔 114 type 〕

〔 Vulcan type 〕

1. PUNCH HOLDER

Hold the punch body. Top of Holder would be connected directly to Press Ram.

2. BODY

It is inserted into the turret and serves as a guide for the punch holder.

3. KEY

Position the turret and the holder. It also serves to hold the tool in place when attached to the turret.

For other parts, please refer to “the thick turret tooling”

PDF Download

-

vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

-

vol.2 LIFE COUNTERMEASURE FOR TOOLING

-

Vol.3 TOOL MAINTENANCE

-

Vol.4 FORMING TOOL

-

Vol.5 MATERIAL FOR TOOLING

-

Vol.6 FOR CLEARANCE OF THE CUTTING DIE

-

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

-

Vol.8 VARIOUS KINDS OF SPECIAL SHAPE

-

Vol.9 PARTS NAME OF STANDARD TOOLING

-

Vol.10 EACH NAMES OF FORMING TOOL

-

Vol.11 MATERIAL PROPERTIES (STEEL)

-

Vol.12 MATERIAL PROPERTIES

-

Vol.13 CALCULATION FORMULAS FREQUENTLY USED IN SHEET METAL

-

Vol.14 HEIGHT ADJUSTMENT FREE TOOL

-

Vol.15 HOW TO DRAW AND READ DRAWINGS

-

Vol.16 HOW TO DRAW AND READ DRAWING (PRACTICAL USE)

-

Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

-

Vol.18 SHAPE INSTRUCTION FOR FORMING TOOLS(2)

-

Vol.19 CODE MANAGEMENT

-

Vol.20 BENDING TECHNICAL INFORMATION

-

Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

-

Vol.22 TECHNICAL COUNSELING FAQ(2) "BURRING FOR THREAD FORM"

-

Vol.23 TECHNICAL COUNSELING FAQ(3) "PITCH OF SINGLE PIERCING"

-

Vol.24 TECHNICAL COUNSELING FAQ(4) "SHEAR OPTIONS"

-

Vol.25 TECHNICAL COUNSELING FAQ(5) "HOLDING MARK"

-

Vol.26 TECHNICAL COUNSELING FAQ(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

-

Vol.27 TECHNICAL COUNSELING FAQ(7) "MATERIAL WARPING PREVENTION DURING"

-

Vol.28 TECHNICAL COUNSELING FAQ(8) "WARPING PREVENTION OF BLANKING OUT"

-

Vol.29 TECHNICAL COUNSELING FAQ(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

-

Vol.30 THE ORDERING GUIDE(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

-

Vol.31 THE ORDERING GUIDE(2) "REFERENCE KEY DIRECTION"

-

Vol.32 THE ORDERING GUIDE(3) "ANGLE INDICATION OF ANGLED TOOL"

-

Vol.33 THE ORDERING GUIDE(4) "SELECT SPECIFICATION OF PUNCH"

-

Vol.34 THE ORDERING GUIDE(5) "DIE SPECIFICATION SELECTION"