Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

Of the questions we received from the Tool Consultation Office,

this time we will introduce “countermeasures for galling during slitting”.

COUNTERMEASURES FOR GALLING WHEN SLITTING PROCESSING

IThe punch and die interfered with each other during slitting, causing galling in the tool.

Is there a way to avoid galling?

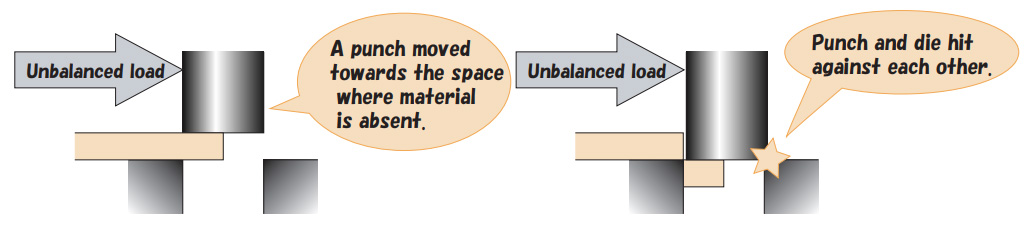

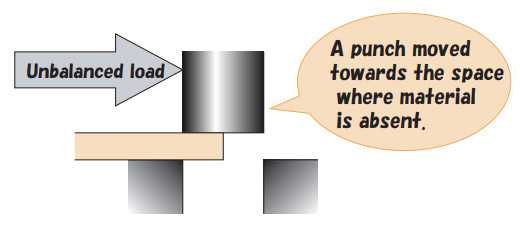

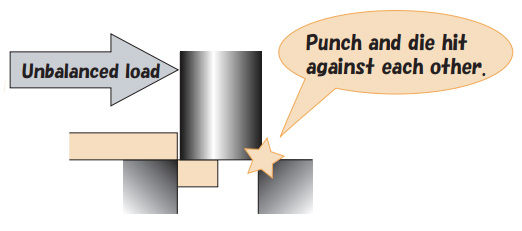

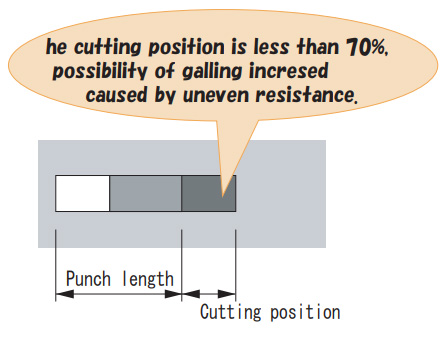

When slitting or cutting the surface of the material, as shown in Fig.1, an unbalanced load is applied to the punch, and interference between punch and die tends to cause burrs in the tool.

Fig.1 Generation of galling due to unbalanced load during slitting

As a countermeasure,

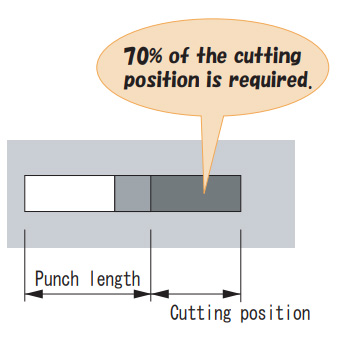

- 1.The cutting position of during slitting, take over 70% of the punch length as a guide.

(See Fig.2)

Fig.2 The cutting position of during slitting

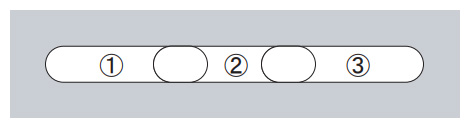

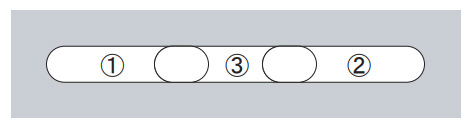

- 2.Change the slitting order

Normal slitting processing order

Processing order with no unbalanced load

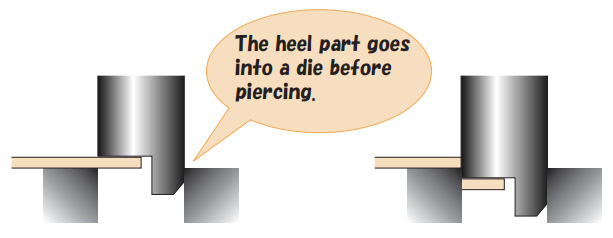

- 3.Use a heel tool. By providing a heel on the punch, it prevents the deviation of the punch due to the unbalanced load.

(See Fig.3)

Fig.3 Prevention of punch misalignment with heeled tool

- 4.It is recommended that the clearance between punch and die be set slightly wider (about 0.1 mm) than normal punching (single punching).

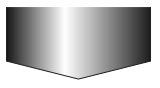

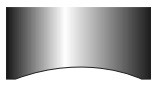

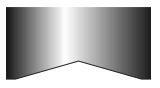

- 5.As for punch shear angle at the time of slitting processing,

"Concave shear " and "Inverted-roof top shear" are more effective than "roof top shear".

(See Fig.4)

Fig.4 Punch shear angle

Roof top

Concave

Inverted roof top

In addition to this, there may be cases such as the occurrence of galling caused by slug pulling,

misalignment or wear of the turret, and tooling installation defects.

For details, please contact Conic Tool Desk.

-

vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

-

vol.2 LIFE COUNTERMEASURE FOR TOOLING

-

Vol.3 TOOL MAINTENANCE

-

Vol.4 FORMING TOOL

-

Vol.5 MATERIAL FOR TOOLING

-

Vol.6 FOR CLEARANCE OF THE CUTTING DIE

-

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

-

Vol.8 VARIOUS KINDS OF SPECIAL SHAPE

-

Vol.9 PARTS NAME OF STANDARD TOOLING

-

Vol.10 EACH NAMES OF FORMING TOOL

-

Vol.11 MATERIAL PROPERTIES (STEEL)

-

Vol.12 MATERIAL PROPERTIES

-

Vol.13 CALCULATION FORMULAS FREQUENTLY USED IN SHEET METAL

-

Vol.14 HEIGHT ADJUSTMENT FREE TOOL

-

Vol.15 HOW TO DRAW AND READ DRAWINGS

-

Vol.16 HOW TO DRAW AND READ DRAWING (PRACTICAL USE)

-

Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

-

Vol.18 SHAPE INSTRUCTION FOR FORMING TOOLS(2)

-

Vol.19 CODE MANAGEMENT

-

Vol.20 BENDING TECHNICAL INFORMATION

-

Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

-

Vol.22 TECHNICAL COUNSELING FAQ(2) "BURRING FOR THREAD FORM"

-

Vol.23 TECHNICAL COUNSELING FAQ(3) "PITCH OF SINGLE PIERCING"

-

Vol.24 TECHNICAL COUNSELING FAQ(4) "SHEAR OPTIONS"

-

Vol.25 TECHNICAL COUNSELING FAQ(5) "HOLDING MARK"

-

Vol.26 TECHNICAL COUNSELING FAQ(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

-

Vol.27 TECHNICAL COUNSELING FAQ(7) "MATERIAL WARPING PREVENTION DURING"

-

Vol.28 TECHNICAL COUNSELING FAQ(8) "WARPING PREVENTION OF BLANKING OUT"

-

Vol.29 TECHNICAL COUNSELING FAQ(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

-

Vol.30 THE ORDERING GUIDE(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

-

Vol.31 THE ORDERING GUIDE(2) "REFERENCE KEY DIRECTION"

-

Vol.32 THE ORDERING GUIDE(3) "ANGLE INDICATION OF ANGLED TOOL"

-

Vol.33 THE ORDERING GUIDE(4) "SELECT SPECIFICATION OF PUNCH"

-

Vol.34 THE ORDERING GUIDE(5) "DIE SPECIFICATION SELECTION"