Vol.20 BENDING TECHNICAL INFORMATION

This time, we summarized the general bending process.

VARIOUS KINDS OF BENDING PROCESSES

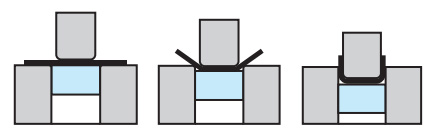

V bend

U bend

L bend

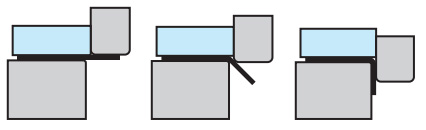

Beading (Rib)

Hemming

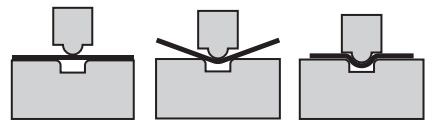

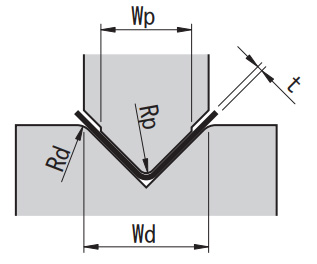

DIMENSIONS OF STANDARD V-BENDING

| Material | Standards | Rp |

| Steel | SPCE S45C,S50C |

(0 - 0.2) x t (0.5 - 1) x t |

| Stainless steel | SUS304 SUS410 |

(0.5 - 1) x t (0.7 - 1.5) x t |

| Aluminum | A1100 A2024 |

(0 - 0.2) x t (0 - 1) x t |

| Copper | Cu | (0 - 0.2) x t |

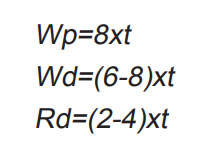

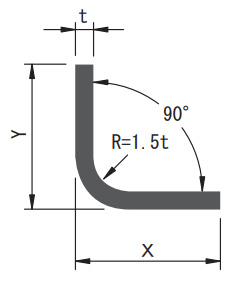

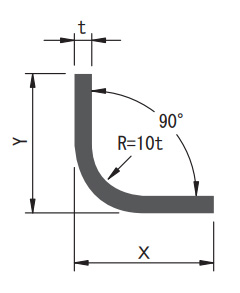

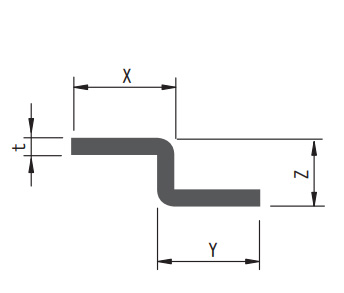

CALCULATION METHOD OF THE EXTEND DIMENSION

Use the following formula to calculate the extend dimensions of the bend.

L = X + Y - 1.5 x t

L = X + Y - 2 x t

L = X + Y - 5.5 x t

L = X + Y + Z - 3 x t

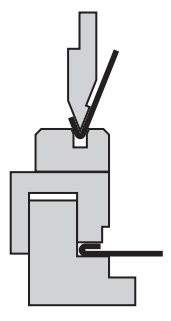

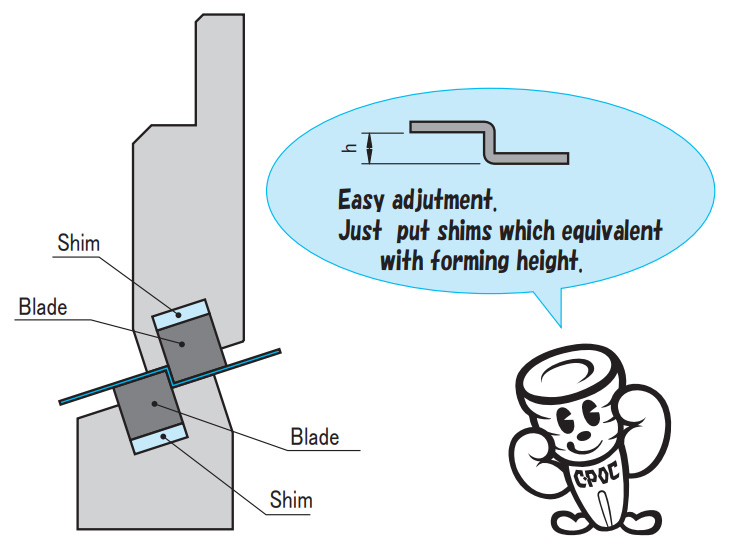

PRODUCT INTRODUCTION:Z bend tool [ DANSAR ]

“DANSAR” can be bent at various steps by changing the thickness of the shim inserted between the body and the blade.

By changing the thickness of the step adjustment shim, it is an epoch-making step bending tool that can be easily set and the concept and ease of setup exceed conventional wisdom.

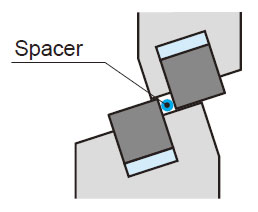

Easy to make proper clearance

by a spacer.

- ●Various combinations are available, such as one-piece and sectional type.

- ●There is also "DANSAR-SUS" with a high-hardness blade set for stainless steel step bending.

Please contact us for more information.

PDF Download

-

vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

-

vol.2 LIFE COUNTERMEASURE FOR TOOLING

-

Vol.3 TOOL MAINTENANCE

-

Vol.4 FORMING TOOL

-

Vol.5 MATERIAL FOR TOOLING

-

Vol.6 FOR CLEARANCE OF THE CUTTING DIE

-

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

-

Vol.8 VARIOUS KINDS OF SPECIAL SHAPE

-

Vol.9 PARTS NAME OF STANDARD TOOLING

-

Vol.10 EACH NAMES OF FORMING TOOL

-

Vol.11 MATERIAL PROPERTIES (STEEL)

-

Vol.12 MATERIAL PROPERTIES

-

Vol.13 CALCULATION FORMULAS FREQUENTLY USED IN SHEET METAL

-

Vol.14 HEIGHT ADJUSTMENT FREE TOOL

-

Vol.15 HOW TO DRAW AND READ DRAWINGS

-

Vol.16 HOW TO DRAW AND READ DRAWING (PRACTICAL USE)

-

Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

-

Vol.18 SHAPE INSTRUCTION FOR FORMING TOOLS(2)

-

Vol.19 CODE MANAGEMENT

-

Vol.20 BENDING TECHNICAL INFORMATION

-

Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

-

Vol.22 TECHNICAL COUNSELING FAQ(2) "BURRING FOR THREAD FORM"

-

Vol.23 TECHNICAL COUNSELING FAQ(3) "PITCH OF SINGLE PIERCING"

-

Vol.24 TECHNICAL COUNSELING FAQ(4) "SHEAR OPTIONS"

-

Vol.25 TECHNICAL COUNSELING FAQ(5) "HOLDING MARK"

-

Vol.26 TECHNICAL COUNSELING FAQ(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

-

Vol.27 TECHNICAL COUNSELING FAQ(7) "MATERIAL WARPING PREVENTION DURING"

-

Vol.28 TECHNICAL COUNSELING FAQ(8) "WARPING PREVENTION OF BLANKING OUT"

-

Vol.29 TECHNICAL COUNSELING FAQ(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

-

Vol.30 THE ORDERING GUIDE(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

-

Vol.31 THE ORDERING GUIDE(2) "REFERENCE KEY DIRECTION"

-

Vol.32 THE ORDERING GUIDE(3) "ANGLE INDICATION OF ANGLED TOOL"

-

Vol.33 THE ORDERING GUIDE(4) "SELECT SPECIFICATION OF PUNCH"

-

Vol.34 THE ORDERING GUIDE(5) "DIE SPECIFICATION SELECTION"