Vol.12 MATERIAL PROPERTIES

As for the materials (workpieces) to be processed by the turret punch press, this time,

we summarized non-ferrous metals, following the previous steel.

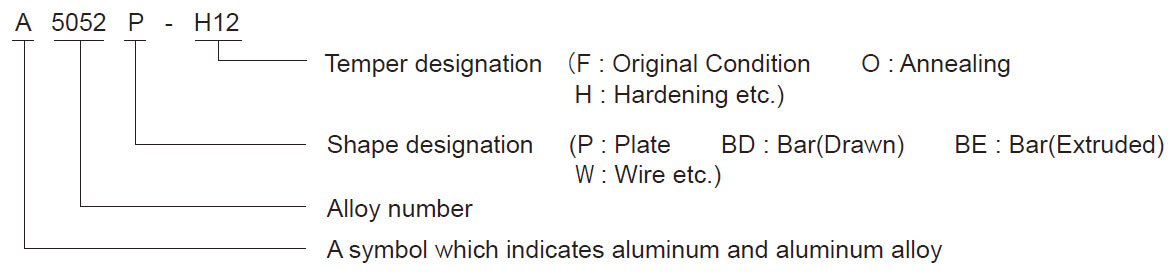

ALUMINIUM AND ALUMINUM ALLOY

Aluminum and aluminum alloy is lightweight and resistant to rust,

so it is used for various purposes in various fields such as lighting fixtures, electric appliances, building materials, various containers, accessories and aircraft materials.

THE MECHANICAL PROPERTIES OF ALUMINUM AND ALUMINUM ALLOY(Excerpt from JIS H4000:1988)

| Symbol | Temper | Tensile Strength N/mm² | Elongation % | Character and application example |

| A 1050 P | 0 | 60 - 100 | Over 15 - 30 |

Low strength because of pure aluminum, but good for forming and corrosion resistance. Reflector, Lightning equipment, Ornaments and so on. |

| H12 | 80 - 120 | Over 2 - 9 | ||

| A 1100 P | 0 | 75 - 110 | Over 15 - 30 |

Low strength, but good for forming, corrosion resistance and welding. Building materials, electrical appliances, containers and so on. |

| H12 | 95 - 125 | Over 2 - 9 | ||

| A 2014 P | 0 | under 215 | Over 10 - 16 |

Heat treated alloy with high strength. Aircraft materials, various structural materials, etc. |

| T4 | Over 410 | Over 14 | ||

| A 2017 P | 0 | under 215 | Over 12 |

Heat treated alloy with high strength. Aircraft materials, various structural materials, etc. |

| T4 | Over 355 | Over 12 - 17 | ||

| A 3003 P | 0 | 95 - 125 | Over 18 - 25 |

A little bit higher in strength than 1100 and good in formability, weldability and corrosion resistance. |

| H12 | 120 - 155 | Over 2 - 9 | ||

| A 5052 P | 0 | 175 - 215 | Over 14 - 20 | Typical alloy with moderate strength. |

| H12 | 215 - 265 | Over 3 - 11 | ||

| A 6061 P | 0 | under 145 | Over 14 - 18 | It has good corrosion resistance and is mainly used as structural material for bolt and rivet connection. |

| T6 | Over 295 | Over 8 - 10 | ||

| A 7075 P | 0 | under 275 | Over 10 |

One of the alloys with the highest strength in aluminum alloy. It is also used as a mold material for injection tooling. |

| T6 | Over 530 | Over 7 - 8 |

| Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| A 1050 P | 0 | 60 - 100 | Over 15 - 30 |

| H12 | 80 - 120 | Over 2 - 9 | |

| Character and application example | |||

|

Low strength because of pure aluminum, but good for forming and corrosion resistance. Reflector, Lightning equipment, Ornaments and so on. |

|||

| Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| A 1100 P | 0 | 75 - 110 | Over 15 - 30 |

| H12 | 95 - 125 | Over 2 - 9 | |

| Character and application example | |||

|

Low strength, but good for forming, corrosion resistance and welding. Building materials, electrical appliances, containers and so on. |

|||

| Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| A 2014 P | 0 | under 215 | Over 10 - 16 |

| T4 | Over 410 | Over 14 | |

| Character and application example | |||

|

Heat treated alloy with high strength. Aircraft materials, various structural materials, etc. |

|||

| Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| A 2017 P | 0 | under 215 | Over 12 |

| T4 | Over 355 | Over 12 - 17 | |

| Character and application example | |||

|

Heat treated alloy with high strength. Aircraft materials, various structural materials, etc. |

|||

| Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| A 3003 P | 0 | 95 - 125 | Over 18 - 25 |

| H12 | 120 - 155 | Over 2 - 9 | |

| Character and application example | |||

|

A little bit higher in strength than 1100 and good in formability, weldability and corrosion resistance. |

|||

| Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| A 5052 P | 0 | 175 - 215 | Over 14 - 20 |

| H12 | 215 - 265 | Over 3 - 11 | |

| Character and application example | |||

| Typical alloy with moderate strength. | |||

| Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| A 6061 P | 0 | under 145 | Over 14 - 18 |

| T6 | Over 295 | Over 8 - 10 | |

| Character and application example | |||

| It has good corrosion resistance and is mainly used as structural material for bolt and rivet connection. | |||

| Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| A 7075 P | 0 | under 275 | Over 10 |

| T6 | Over 530 | Over 7 - 8 | |

| Character and application example | |||

| One of the alloys with the highest strength in aluminum alloy. It is also used as a mold material for injection tooling. |

|||

<Note>1 N/mm² ≒ 0.102kgf/mm²

ADVICE ON ONE POINT

Aluminum is a material with relatively good workability, but because of its softness,

marks like a guide may stick to the workpiece or burrs may occur during punching.

Adjustment such as weakening the force holding the work (spring strength) or reducing the clearance may be necessary.

(Please refer to Technical Information Vol. 22)

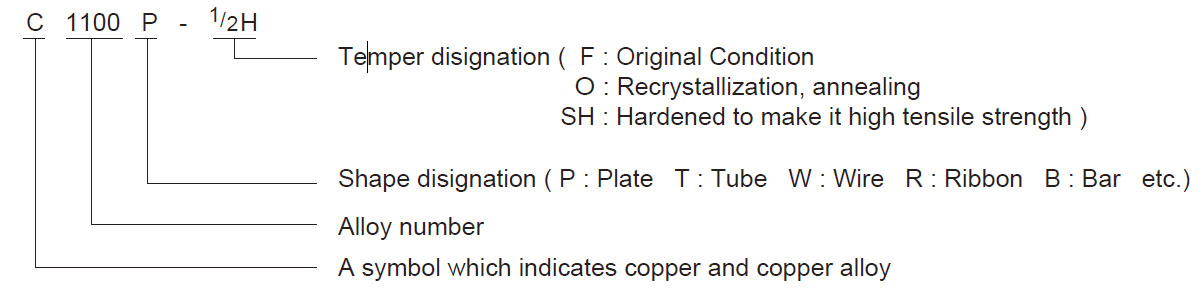

COPPER AND COPPER ALLOY

Copper and copper alloys have good electrical and thermal conductivity and are beautiful in gloss,

so they are used for electrical appliances, wiring equipment, building tools, accessories, etc.

THE MECHANICAL PROPERTIES OF COPPER AND COPPER ALLOY(Excerpt from JIS H3100 H3110 H3130:1992)

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % | Character and application example |

| Tough Pitch copper | C 1100 P | 0 | Over 195 | Over 35 | It has excellent electrical and thermal conductivity, good ductility, drawing workability and corrosion resistance. |

| 1/2 H | 245 - 315 | Over 15 | |||

| Tombac | C 2200 P | 0 | Over 225 | Over 35 | The color is beautiful, ductility; drawing workability and corrosion resistance are good. |

| 1/2 H | 285 - 365 | Over 20 | |||

| Brass | C 2600 P | 0 | Over 275 | Over 40 - 50 | It has excellent in ductility and deep drawing processability and good in plating properties. |

| 1/2 H | 335 - 440 | Over 28 | |||

| C 2680 P | 0 | Under275 | Over 40 - 50 | Good ductility, drawability, and plating properties. | |

| 1/2 H | 355 - 440 | Over 28 | |||

| Free Cutting Brass | C 3560 P | 1/4 H | 345 - 430 | Over 18 | Especially excellent in machinability and good punching property. Clock parts, gears etc. |

| H | Over 420 | ― | |||

| C 3710 P | 1/4 H | 375 - 460 | Over 20 |

Especially excellent punching property and good machinability. Clock parts, gears etc. |

|

| H | Over 470 | ― | |||

| Phosphor bronze | C 5111 P | 0 | Over 295 | Over 38 |

Good spreadability, fatigue resistance and corrosion resistance. Switch, lead frame, connector, etc. |

| 1/2 H | 410 - 510 | Over 12 | |||

| Cupronickel | C 7060 P | F | Over 275 | Over 30 | Corrosion resistance, especially sea water resistance is good; it is suitable for use at relatively high temperature. |

| Nickel Silver | C 7351 P | 0 | Over 325 | Over 20 |

Luster is beautiful, ductility, fatigue resistance, corrosion resistance are good. |

| 1/2 H | 390 - 510 | Over 5 | |||

| Copper beryllium alloy for springs | C 1720 P | 0 | 410 - 540 | Over 35 |

Good corrosion resistance. High performance springs, springs for electric appliances, etc. |

| 1/2 H | 590 - 695 | Over 5 | |||

| Phosphor bronze for springs | C 5210 P | 1/2 H | 470 - 610 | Over 27 | Good ductility, fatigue resistance and corrosion resistance. |

| EH | 685 - 785 | Over 11 |

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| Tough Pitch copper | C 1100 P | 0 | Over 195 | Over 35 |

| 1/2 H | 245 - 315 | Over 15 | ||

| Character and application example | ||||

| It has excellent electrical and thermal conductivity, good ductility, drawing workability and corrosion resistance. | ||||

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| Tombac | C 2200 P | 0 | Over 225 | Over 35 |

| 1/2 H | 285 - 365 | Over 20 | ||

| Character and application example | ||||

| The color is beautiful, ductility; drawing workability and corrosion resistance are good. | ||||

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| Brass | C 2600 P | 0 | Over 275 | Over 40 - 50 |

| 1/2 H | 335 - 440 | Over 28 | ||

| Character and application example | ||||

| It has excellent in ductility and deep drawing processability and good in plating properties. | ||||

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| Brass | C 2680 P | 0 | Under275 | Over 40 - 50 |

| 1/2 H | 355 - 440 | Over 28 | ||

| Character and application example | ||||

| Good ductility, drawability, and plating properties. | ||||

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| Free Cutting Brass | C 3560 P | 1/4 H | 345 - 430 | Over 18 |

| H | Over 420 | ― | ||

| Character and application example | ||||

| Especially excellent in machinability and good punching property. Clock parts, gears etc. |

||||

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| Free Cutting Brass | C 3710 P | 1/4 H | 375 - 460 | Over 20 |

| H | Over 470 | ― | ||

| Character and application example | ||||

| Especially excellent punching property and good machinability. Clock parts, gears etc. |

||||

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| Phosphor bronze | C 5111 P | 0 | Over 295 | Over 38 |

| 1/2 H | 410 - 510 | Over 12 | ||

| Character and application example | ||||

| Good spreadability, fatigue resistance and corrosion resistance. Switch, lead frame, connector, etc. |

||||

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| Cupronickel | C 7060 P | F | Over 275 | Over 30 |

| Character and application example | ||||

| Corrosion resistance, especially sea water resistance is good; it is suitable for use at relatively high temperature. | ||||

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| Nickel Silver | C 7351 P | 0 | Over 325 | Over 20 |

| 1/2 H | 390 - 510 | Over 5 | ||

| Character and application example | ||||

| Luster is beautiful, ductility, fatigue resistance, corrosion resistance are good. |

||||

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| Copper beryllium alloy for springs | C 1720 P | 0 | 410 - 540 | Over 35 |

| 1/2 H | 590 - 695 | Over 5 | ||

| Character and application example | ||||

| Good corrosion resistance. High performance springs, springs for electric appliances, etc. |

||||

| Name | Symbol | Temper | Tensile Strength N/mm² | Elongation % |

| Phosphor bronze for springs | C 5210 P | 1/2 H | 470 - 610 | Over 27 |

| EH | 685 - 785 | Over 11 | ||

| Character and application example | ||||

| Good ductility, fatigue resistance and corrosion resistance. | ||||

<Note>1 N/mm² ≒ 0.102kgf/mm²

Reference from JIS Handbook (Nonferrous metals) : Japanese Standard Association

PDF Download

-

vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

-

vol.2 LIFE COUNTERMEASURE FOR TOOLING

-

Vol.3 TOOL MAINTENANCE

-

Vol.4 FORMING TOOL

-

Vol.5 MATERIAL FOR TOOLING

-

Vol.6 FOR CLEARANCE OF THE CUTTING DIE

-

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

-

Vol.8 VARIOUS KINDS OF SPECIAL SHAPE

-

Vol.9 PARTS NAME OF STANDARD TOOLING

-

Vol.10 EACH NAMES OF FORMING TOOL

-

Vol.11 MATERIAL PROPERTIES (STEEL)

-

Vol.12 MATERIAL PROPERTIES

-

Vol.13 CALCULATION FORMULAS FREQUENTLY USED IN SHEET METAL

-

Vol.14 HEIGHT ADJUSTMENT FREE TOOL

-

Vol.15 HOW TO DRAW AND READ DRAWINGS

-

Vol.16 HOW TO DRAW AND READ DRAWING (PRACTICAL USE)

-

Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

-

Vol.18 SHAPE INSTRUCTION FOR FORMING TOOLS(2)

-

Vol.19 CODE MANAGEMENT

-

Vol.20 BENDING TECHNICAL INFORMATION

-

Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

-

Vol.22 TECHNICAL COUNSELING FAQ(2) "BURRING FOR THREAD FORM"

-

Vol.23 TECHNICAL COUNSELING FAQ(3) "PITCH OF SINGLE PIERCING"

-

Vol.24 TECHNICAL COUNSELING FAQ(4) "SHEAR OPTIONS"

-

Vol.25 TECHNICAL COUNSELING FAQ(5) "HOLDING MARK"

-

Vol.26 TECHNICAL COUNSELING FAQ(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

-

Vol.27 TECHNICAL COUNSELING FAQ(7) "MATERIAL WARPING PREVENTION DURING"

-

Vol.28 TECHNICAL COUNSELING FAQ(8) "WARPING PREVENTION OF BLANKING OUT"

-

Vol.29 TECHNICAL COUNSELING FAQ(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

-

Vol.30 THE ORDERING GUIDE(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

-

Vol.31 THE ORDERING GUIDE(2) "REFERENCE KEY DIRECTION"

-

Vol.32 THE ORDERING GUIDE(3) "ANGLE INDICATION OF ANGLED TOOL"

-

Vol.33 THE ORDERING GUIDE(4) "SELECT SPECIFICATION OF PUNCH"

-

Vol.34 THE ORDERING GUIDE(5) "DIE SPECIFICATION SELECTION"