Vol.29 TECHNICAL COUNSELING FAQ(9)

"COUNTERSINK FOR COUNTERSUNK SCREW"

COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

Also, please tell me if you have any point to pay attention to.

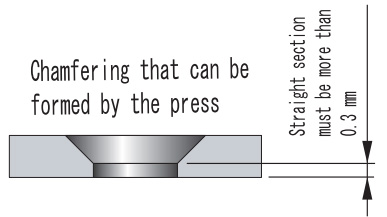

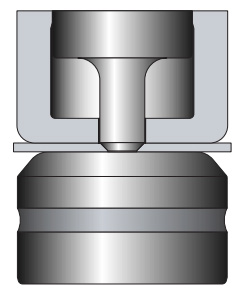

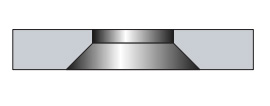

With a turret punch press, countersunk processing can be formed to sink the countersunk screw (chamfering) and rivet head.(see.Fig.1)

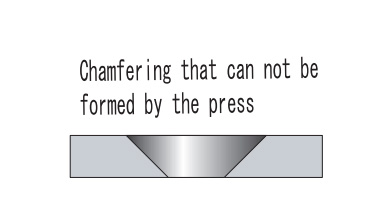

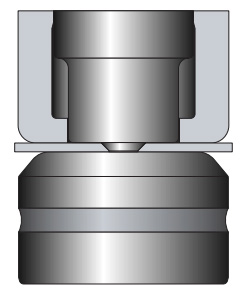

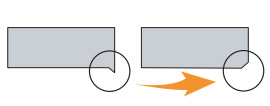

However, as shown in Fig.2-2, a countersink with a taper from the front to the back of the workpiece (material) cannot be manufactured because the punch and die contact each other.

A straight is required, as shown in Fig. 2-1.

Fig.1 Chamfering formed by press

Fig.2-1

Fig.2-2

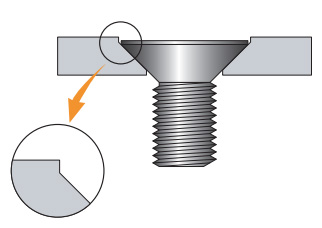

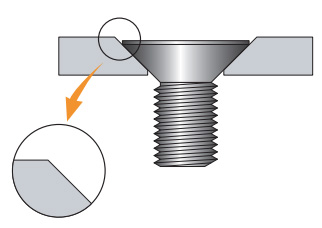

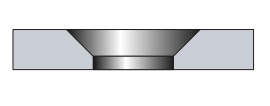

There are two types of the chamfer shape as shown in Fig.3.

- 1.Chamfer with a straight section

-

2.

Chamfer without a straight section

Type 1 looks better when a countersunk screw is inserted,

and we adopt this shape as standard.

Fig.3 The type of camfering

| TYPE 1 | TYPE 2 |

|

|

In addition, there are two tool structures as shown in Fig. 4.

- 1. A type that presses around the formed part with a guide (our standard specification)

- 2. A type that presses the periphery of the formed part with the punch flange.

Fig.4 Type of tooling structure (e.g. Downward)

| 1. Standard type | 2. Flange type |

|

|

Advantages of flange type are …

- 1. Protect the swelling around the chamfer.

-

2.

Punch strength improvement

(break prevention). - 3. Reduce variation in bottom dead center during forming.

Disadvantages of flange type are …

- 4. The chamfer depth cannot be adjusted.

- 5. There might be a holding mark on the flange.

For C-chamfering, there are processing types as shown in Fig. 5.

Chamfering is possible not only for round shapes but also for square and irregular shaped holes.

Edge cutting is a tool that chamfers by pressing the burr after punching out.

Deburring (chamfering) can be processed by using tool that matches the shape of the R-shaped part and curved part as well as the straight part.

Fig.5 Type of C-chamfering

| Down wards | Up wards | Up, Down same time | Edge cutting tool |

|

|

|

|

ADVICE ON ONE POINT

-

1.

The head diameter of the standard countersunk screw is twice the nominal diameter of the screw,

but some sash screws are one or two times smaller than the standard head diameter.

Please be careful when ordering tools. -

2.

In the case of chamfer for rivets, the taper angle is various, such as 100°,

110°, and 120°. Please refer to your rivet catalog. -

3.

When the amount of chamfering is large, raised parts and gloss appear around the chamfer.

In such a case, please enlarge the pre-hole.

-

vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

-

vol.2 LIFE COUNTERMEASURE FOR TOOLING

-

Vol.3 TOOL MAINTENANCE

-

Vol.4 FORMING TOOL

-

Vol.5 MATERIAL FOR TOOLING

-

Vol.6 FOR CLEARANCE OF THE CUTTING DIE

-

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

-

Vol.8 VARIOUS KINDS OF SPECIAL SHAPE

-

Vol.9 PARTS NAME OF STANDARD TOOLING

-

Vol.10 EACH NAMES OF FORMING TOOL

-

Vol.11 MATERIAL PROPERTIES (STEEL)

-

Vol.12 MATERIAL PROPERTIES

-

Vol.13 CALCULATION FORMULAS FREQUENTLY USED IN SHEET METAL

-

Vol.14 HEIGHT ADJUSTMENT FREE TOOL

-

Vol.15 HOW TO DRAW AND READ DRAWINGS

-

Vol.16 HOW TO DRAW AND READ DRAWING (PRACTICAL USE)

-

Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

-

Vol.18 SHAPE INSTRUCTION FOR FORMING TOOLS(2)

-

Vol.19 CODE MANAGEMENT

-

Vol.20 BENDING TECHNICAL INFORMATION

-

Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

-

Vol.22 TECHNICAL COUNSELING FAQ(2) "BURRING FOR THREAD FORM"

-

Vol.23 TECHNICAL COUNSELING FAQ(3) "PITCH OF SINGLE PIERCING"

-

Vol.24 TECHNICAL COUNSELING FAQ(4) "SHEAR OPTIONS"

-

Vol.25 TECHNICAL COUNSELING FAQ(5) "HOLDING MARK"

-

Vol.26 TECHNICAL COUNSELING FAQ(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

-

Vol.27 TECHNICAL COUNSELING FAQ(7) "MATERIAL WARPING PREVENTION DURING"

-

Vol.28 TECHNICAL COUNSELING FAQ(8) "WARPING PREVENTION OF BLANKING OUT"

-

Vol.29 TECHNICAL COUNSELING FAQ(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

-

Vol.30 THE ORDERING GUIDE(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

-

Vol.31 THE ORDERING GUIDE(2) "REFERENCE KEY DIRECTION"

-

Vol.32 THE ORDERING GUIDE(3) "ANGLE INDICATION OF ANGLED TOOL"

-

Vol.33 THE ORDERING GUIDE(4) "SELECT SPECIFICATION OF PUNCH"

-

Vol.34 THE ORDERING GUIDE(5) "DIE SPECIFICATION SELECTION"