Vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

One of the problems that occur when punching with an NC turret punch press is slug pulling.

It is generally said that slug pulling are round or simple in shape and often occur when the thick plate is thin.

This chapter summarized some measures, including slug catcher die, for this slug pulling.

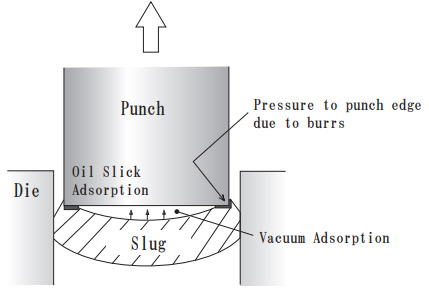

Mechanism of slug pulling

- A.Vacuum adsorption

- B.Oil film adsorption

- C.Magnetic adsorption

- D.Cutting edge pressure bonding by burrs etc.

Countermeasures for slug pulling

Slug Catcher Die(Standard specification)

Catch the slug to prevent slug pulling.

![① Material is cut off at [A] part.](../../images/tech/vol1_2.jpg)

① Material is cut off at [A] part.

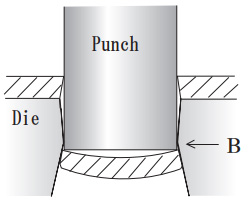

![② The slug is compressed in the process of punching at [B] part.](../../images/tech/vol1_3.jpg)

② The slug is compressed

in the process of

punching at [B] part.

③ Drags the slug through the relief.

![④ [B] part is narrower than [C] part so the slug cannot comes up.](../../images/tech/vol1_5.jpg)

④ [B] part is narrower

than [C] part so the

slug cannot comes up.

COUNTERMEASURE FOR UPPER DIE (PUNCH SIDE)

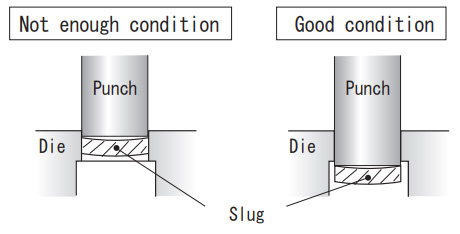

1) ADUST I NG UPPER TOOL I NG HEIGHT

Insert punch edge deeply to inside the die to push the slug properly.

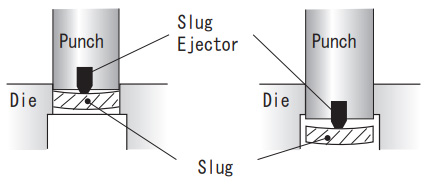

2) SLUG EJECTOR(STANDARD SPECIFICATION)

The slug ejector attached to the cutting edge of the punch forcibly removes scraps.

(Preventing adhesion/ adsorption)

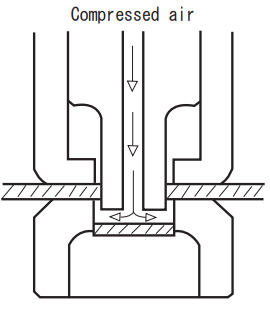

3) COMPRESSED AIR

The compressed air is discharged directly from the air hole of the tool center and blown to the slug to forcibly remove the slug.

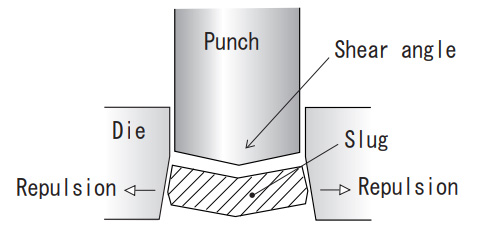

4) SHEAR ANGLE

By attaching a shear angle to the cutting edge of the punch, the slug is deformed and its repulsive force (spring-back) is used to prevent slug pulling.

COUNTERMEASURE FOR LOWER DIE(DIE SIDE)

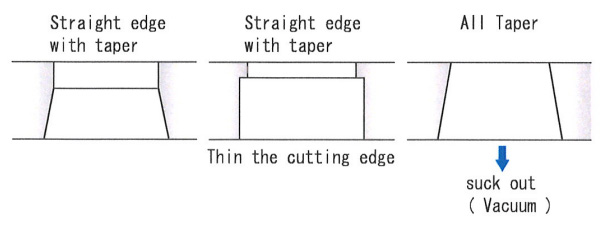

1) SELECTION OF DIE CUTTING EDGE

The cutting edge has the following specifications in addition to the slug catcher.

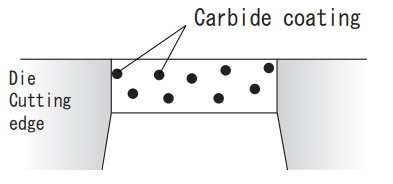

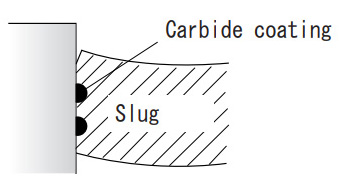

2) DEPOSITION PROCESS(D Process)

It makes electric welding the carbide coating film onto the side of the die cutting edgeand catches the slug.

Other Solution

- 1.Do not use the processing oil.

- 2.Use with an appropriate clearance.

- 3.Do enough demagnetizing.

We recommend that you try these methods individually or in combination,

depending on the material, thickness and punched form of the workpiece.

-

vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

-

vol.2 LIFE COUNTERMEASURE FOR TOOLING

-

Vol.3 TOOL MAINTENANCE

-

Vol.4 FORMING TOOL

-

Vol.5 MATERIAL FOR TOOLING

-

Vol.6 FOR CLEARANCE OF THE CUTTING DIE

-

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

-

Vol.8 VARIOUS KINDS OF SPECIAL SHAPE

-

Vol.9 PARTS NAME OF STANDARD TOOLING

-

Vol.10 EACH NAMES OF FORMING TOOL

-

Vol.11 MATERIAL PROPERTIES (STEEL)

-

Vol.12 MATERIAL PROPERTIES

-

Vol.13 CALCULATION FORMULAS FREQUENTLY USED IN SHEET METAL

-

Vol.14 HEIGHT ADJUSTMENT FREE TOOL

-

Vol.15 HOW TO DRAW AND READ DRAWINGS

-

Vol.16 HOW TO DRAW AND READ DRAWING (PRACTICAL USE)

-

Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

-

Vol.18 SHAPE INSTRUCTION FOR FORMING TOOLS(2)

-

Vol.19 CODE MANAGEMENT

-

Vol.20 BENDING TECHNICAL INFORMATION

-

Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

-

Vol.22 TECHNICAL COUNSELING FAQ(2) "BURRING FOR THREAD FORM"

-

Vol.23 TECHNICAL COUNSELING FAQ(3) "PITCH OF SINGLE PIERCING"

-

Vol.24 TECHNICAL COUNSELING FAQ(4) "SHEAR OPTIONS"

-

Vol.25 TECHNICAL COUNSELING FAQ(5) "HOLDING MARK"

-

Vol.26 TECHNICAL COUNSELING FAQ(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

-

Vol.27 TECHNICAL COUNSELING FAQ(7) "MATERIAL WARPING PREVENTION DURING"

-

Vol.28 TECHNICAL COUNSELING FAQ(8) "WARPING PREVENTION OF BLANKING OUT"

-

Vol.29 TECHNICAL COUNSELING FAQ(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

-

Vol.30 THE ORDERING GUIDE(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

-

Vol.31 THE ORDERING GUIDE(2) "REFERENCE KEY DIRECTION"

-

Vol.32 THE ORDERING GUIDE(3) "ANGLE INDICATION OF ANGLED TOOL"

-

Vol.33 THE ORDERING GUIDE(4) "SELECT SPECIFICATION OF PUNCH"

-

Vol.34 THE ORDERING GUIDE(5) "DIE SPECIFICATION SELECTION"