Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

We summarized the shape / dimension instructions and precautions when ordering tools.

When ordering forming tools, please specify the following in addition to the shape instructions.

- ●Thickness of material, Kind of material

- ●Forming Up or Forming Down

- ●Processing pitch, presence of other tools that may interfere with the forming tools.

DIMENSION INSTRUCTION METHOD FOR VARIOUS KINDS OF FORMING TOOLS

| FORMING SHAPES | INSTRUCTIONS | ||||||||||||

|

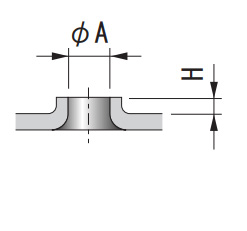

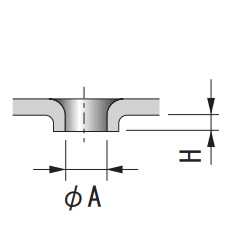

■ Center Point 〔 FORMING UP 〕

〔 FORMING DOWN 〕

|

|

||||||||||||

|

■ Burring for thread form 〔 FORMING UP 〕

〔 FORMING DOWN 〕

|

|

||||||||||||

|

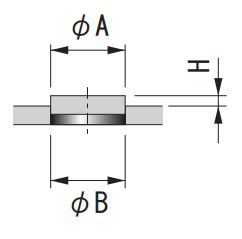

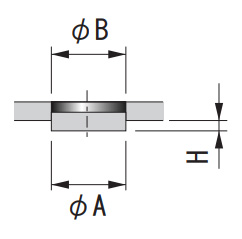

■ Half Shear 〔 FORMING UP 〕

〔 FORMING DOWN 〕

|

|

||||||||||||

|

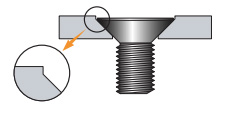

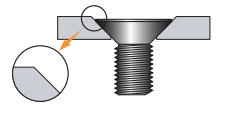

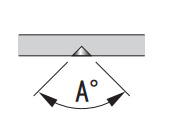

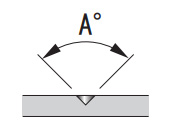

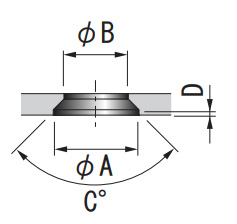

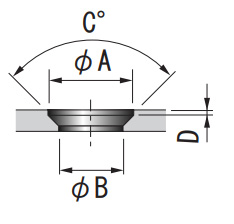

■ Countersink for countersunk screw (Chamfering) 〔 FORMING UP 〕

〔 FORMING DOWN 〕

|

|

||||||||||||

|

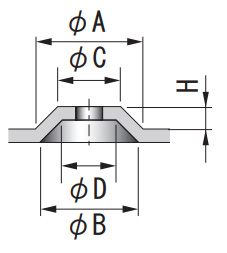

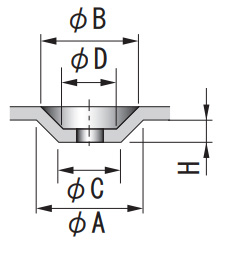

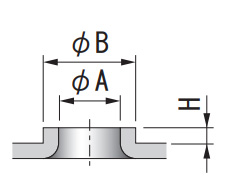

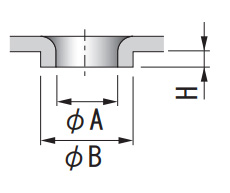

■ Emboss 〔 FORMING UP 〕

〔 FORMING DOWN 〕

|

|

||||||||||||

|

■ Burring (Extrusion) 〔 FORMING UP 〕

〔 FORMING DOWN 〕

|

|

||||||||||||

|

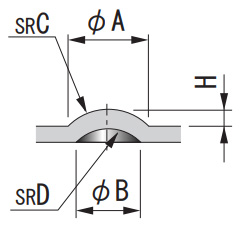

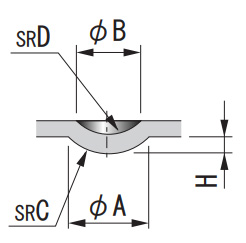

■ Emboss (Dimple) 〔 FORMING UP 〕

〔 FORMING DOWN 〕

|

|

PDF Download

-

vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

-

vol.2 LIFE COUNTERMEASURE FOR TOOLING

-

Vol.3 TOOL MAINTENANCE

-

Vol.4 FORMING TOOL

-

Vol.5 MATERIAL FOR TOOLING

-

Vol.6 FOR CLEARANCE OF THE CUTTING DIE

-

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

-

Vol.8 VARIOUS KINDS OF SPECIAL SHAPE

-

Vol.9 PARTS NAME OF STANDARD TOOLING

-

Vol.10 EACH NAMES OF FORMING TOOL

-

Vol.11 MATERIAL PROPERTIES (STEEL)

-

Vol.12 MATERIAL PROPERTIES

-

Vol.13 CALCULATION FORMULAS FREQUENTLY USED IN SHEET METAL

-

Vol.14 HEIGHT ADJUSTMENT FREE TOOL

-

Vol.15 HOW TO DRAW AND READ DRAWINGS

-

Vol.16 HOW TO DRAW AND READ DRAWING (PRACTICAL USE)

-

Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

-

Vol.18 SHAPE INSTRUCTION FOR FORMING TOOLS(2)

-

Vol.19 CODE MANAGEMENT

-

Vol.20 BENDING TECHNICAL INFORMATION

-

Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

-

Vol.22 TECHNICAL COUNSELING FAQ(2) "BURRING FOR THREAD FORM"

-

Vol.23 TECHNICAL COUNSELING FAQ(3) "PITCH OF SINGLE PIERCING"

-

Vol.24 TECHNICAL COUNSELING FAQ(4) "SHEAR OPTIONS"

-

Vol.25 TECHNICAL COUNSELING FAQ(5) "HOLDING MARK"

-

Vol.26 TECHNICAL COUNSELING FAQ(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

-

Vol.27 TECHNICAL COUNSELING FAQ(7) "MATERIAL WARPING PREVENTION DURING"

-

Vol.28 TECHNICAL COUNSELING FAQ(8) "WARPING PREVENTION OF BLANKING OUT"

-

Vol.29 TECHNICAL COUNSELING FAQ(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

-

Vol.30 THE ORDERING GUIDE(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

-

Vol.31 THE ORDERING GUIDE(2) "REFERENCE KEY DIRECTION"

-

Vol.32 THE ORDERING GUIDE(3) "ANGLE INDICATION OF ANGLED TOOL"

-

Vol.33 THE ORDERING GUIDE(4) "SELECT SPECIFICATION OF PUNCH"

-

Vol.34 THE ORDERING GUIDE(5) "DIE SPECIFICATION SELECTION"