Vol.6 FOR CLEARANCE OF THE CUTTING DIE

Selection of the die clearance also has a significant impact on the quality of the workpiece and the tool life.

This time, we summarized the selection criteria of the clearance. Also we will introduce "one pitch thread form" as a forming tool.

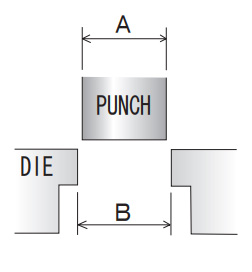

WHAT IS CLEARANCE ?

Clearance refers to difference in dimension

between punch dimension and die dimension.

REFERENCE APPROPRIATE CLEARANCE

| Material | Clearance Ratio | Tensile Strength (N/㎟) |

|

| Servo / Hydraulic Machine | Mechanical Machine | ||

| Mild Steel (Cold Roll) |

0.2~0.25 | 0.15 | More than 270~ |

| Mild Steel (Hot Roll) |

|||

| Stainles (Hard) |

0.2~0.3 | 0.2 | More than 520~ |

| Stainless (Soft) |

More than 450~ |

||

| Aluminum (Hard) |

0.15~0.25 | 0.1 | More than 215~ |

| Alminium(Soft) | More than 95~ |

||

| Copper | 0.2~0.25 | 0.15 | More than 275~ |

| Brass | 0.2~0.3 | 0.2 | More than 410~ |

| High Tensile Steel | More than 590~ |

||

- 1.The shear resistance should be about 80% of the tensile strength as a guide.

- 2.Please multiply x 1.4 to the calculation result in case of more than 3.2mm thickness.

- 3.Please calculate based on the number of shear resistance and Tensile strength for the material which is unspecified on the left table.

- 4.If there is a workpiece, please actually perform punching and purchase the appropriate clearance referring to the table below.

- 5.The minimum clearance is depends on machine specifications. Please also check the machine specifications.

THE INFLUENCE BETWEEN CLEARANCE AND MATERIAL(PRODUCT)

| Clearance | Wide | Proper | Narrow |

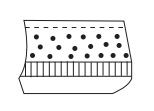

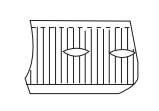

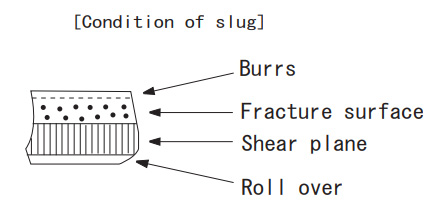

| Conditio of slug |

|

|

|

| Roll over | MORE | NORMAL | LESS |

| Shear plane | LESS | NORMAL | MORE |

| Fracture surface | MORE | NORMAL | LESS |

| Burrs | MORE | LITTLE | LITTLE |

| Warp | MORE | LITTLE | LITTLE |

| Accuracy in dimension |

WORSE | BETTER | BETTER |

| Comment | Negative influence of slug pulling | Increase tonnage |

〔 Condition of slug 〕

ONE PITCH THREAD FORM

UNNECESSARY TAPPING PROCESS!

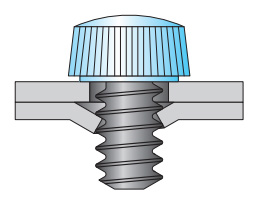

We recommend one pitch thread form for screwing in places where relatively strong strength is not required, such as decorative panels and covers.

One pitch thread form is…

- ・Process that uses a turret punch press to form one pitch of screws on a material.

- ・After pre-hole (Round punching) processing, it can be easily processed by forming. Also it can be processed at high speed compared to tapping.

- ・High speed punching press compared to tapping process.

- ・If the screw size is the same, it can be formed with the same tool even if the plate thickness is different.

(Adjustment of the punch length is necessary.)

〔 Example of use 〕

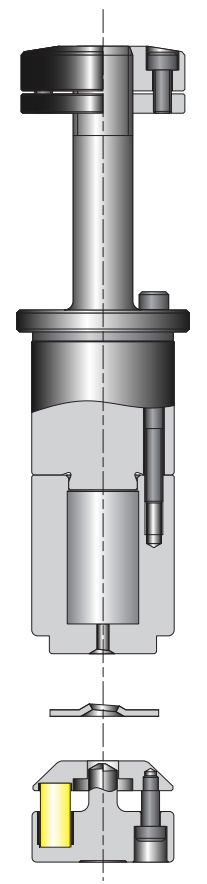

TOOLING STRUCTURE (NC 1-1/4)

Process Procedure

Applicability

Thickness of material :

0.6mm ~ 1.6mm

Thread Size : M3 ~ M8

-

※Please consult the tool sales desk

for Non-Standard dimension.

| Recommended tool size | |

| Thick Turret Type | 1-1/4 (B) station |

| MURATA 114 type | C or D station |

〔 FORMING DOWN 〕

〔 FORMING UP 〕

PDF Download

-

vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

-

vol.2 LIFE COUNTERMEASURE FOR TOOLING

-

Vol.3 TOOL MAINTENANCE

-

Vol.4 FORMING TOOL

-

Vol.5 MATERIAL FOR TOOLING

-

Vol.6 FOR CLEARANCE OF THE CUTTING DIE

-

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

-

Vol.8 VARIOUS KINDS OF SPECIAL SHAPE

-

Vol.9 PARTS NAME OF STANDARD TOOLING

-

Vol.10 EACH NAMES OF FORMING TOOL

-

Vol.11 MATERIAL PROPERTIES (STEEL)

-

Vol.12 MATERIAL PROPERTIES

-

Vol.13 CALCULATION FORMULAS FREQUENTLY USED IN SHEET METAL

-

Vol.14 HEIGHT ADJUSTMENT FREE TOOL

-

Vol.15 HOW TO DRAW AND READ DRAWINGS

-

Vol.16 HOW TO DRAW AND READ DRAWING (PRACTICAL USE)

-

Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

-

Vol.18 SHAPE INSTRUCTION FOR FORMING TOOLS(2)

-

Vol.19 CODE MANAGEMENT

-

Vol.20 BENDING TECHNICAL INFORMATION

-

Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

-

Vol.22 TECHNICAL COUNSELING FAQ(2) "BURRING FOR THREAD FORM"

-

Vol.23 TECHNICAL COUNSELING FAQ(3) "PITCH OF SINGLE PIERCING"

-

Vol.24 TECHNICAL COUNSELING FAQ(4) "SHEAR OPTIONS"

-

Vol.25 TECHNICAL COUNSELING FAQ(5) "HOLDING MARK"

-

Vol.26 TECHNICAL COUNSELING FAQ(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

-

Vol.27 TECHNICAL COUNSELING FAQ(7) "MATERIAL WARPING PREVENTION DURING"

-

Vol.28 TECHNICAL COUNSELING FAQ(8) "WARPING PREVENTION OF BLANKING OUT"

-

Vol.29 TECHNICAL COUNSELING FAQ(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

-

Vol.30 THE ORDERING GUIDE(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

-

Vol.31 THE ORDERING GUIDE(2) "REFERENCE KEY DIRECTION"

-

Vol.32 THE ORDERING GUIDE(3) "ANGLE INDICATION OF ANGLED TOOL"

-

Vol.33 THE ORDERING GUIDE(4) "SELECT SPECIFICATION OF PUNCH"

-

Vol.34 THE ORDERING GUIDE(5) "DIE SPECIFICATION SELECTION"