Vol.11 MATERIAL PROPERTIES (STEEL)

In the turret punch press, various materials (workpieces) are processed.

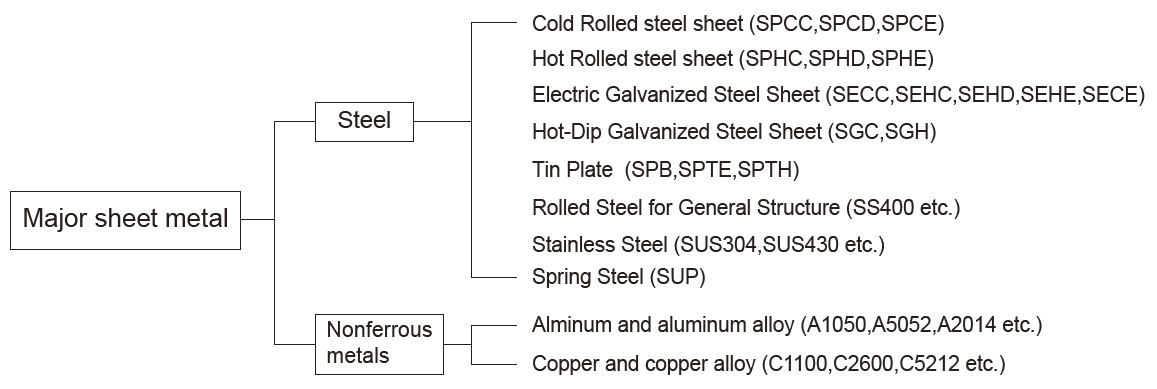

The materials used for sheet metal processing are various, such as steel and nonferrous metals,

and the names also differ according to each maker.

This time, we summarized the typical steel materials for metal forming.

TYPICAL METAL FORMING MATERIALS

COLD ROLLED STEEL SHEET

It is a typical steel material of sheet metal material rolled at near normal temperature.

It is inexpensive in price and good in processability, and it is a plate material whose surface is clean because it is rolling at normal temperature.

Usually SPCC (for general use) is often used, but if problems occur with forming, we recommend SPCD (for forming) and SPCE (for deep forming).

HOT ROLLED STEEL SHEET

It is a material rolled at high temperature and has plate thickness of 1.2 ~ (14)mm.

Because of hot rolling, scales are attached to the surface of the plate.

There are also steel plates that have been removed scales by acid cleaning or shot blasting.

It is recommended to take a slightly wider clearance than the Cold Rolled Steel.

| Material | JIS symbol | Thickness mm | Remark | Tensile Strength N/mm² | Elongation % |

| Cold Rolled Steel | SPCC | 0.4 - 3.2 | General | (Over 270) | (Over 32 - 39) |

| SPCD | 0.4 - 3.2 | For Emboss | Over 270 | Over 35 - 41 | |

| SPCE | 0.4 - 3.2 | For Deep Emboss | Over 270 | Over 36 - 43 | |

| Hot Rolled Steel | SPHC | 1.2 - 14 | General | Over 270 | Over 27 - 31 |

| SPHD | 1.2~14 | For Emboss | Over 270 | Over 30 - 39 | |

| SPHE | 1.2 - 6 | for Deep Emboss | Over 270 | Over 31 - 41 |

< Reference >1² N/mm ≒ 0.102kgf/mm²

ELECTRIC GALVANIZED STEEL SHEET

Electrogalvanized on cold-rolled steel sheet and hot-rolled steel sheet raw material,

widely used for home appliances, automotive parts, etc.

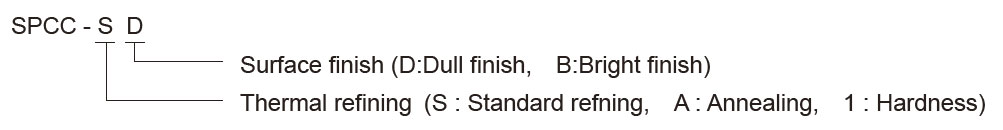

SYMBOL OF ELECTRIC GALVANIZED STEEL SHEET

| Material | Thickness | Remark | Symbol | Original Sheet |

| Cold Rolled Steel | 0.4 - 3.2 | General For Emboss For Deep Emboss |

SECC | SPCC |

| SECD | SPCD | |||

| SECE | SPCE | |||

| Hot Rolled Steel | 1.6 - 4.5 | General For Emboss For Deep Emboss |

SEHC | SPHC |

| SEHD | SPHD | |||

| SEHE | SPHE |

HOT-DIP GALVANIZED STEEL SHEET

Hot-dip galvanized steel sheet is a material obtained by hot-dip galvanizing plating of cold-rolled steel sheet or hot-rolled mild steel plate,

has high corrosion resistance due to thick plating layer,

and is used for exterior building materials and outdoor equipment.

ADVICE ON ONE POINT

When punching a plated steel sheet, the plating may peel off and enter the inside of the tool (sliding part),

which may cause seizure. It is advisable to carry out maintenance earlier and remove the plating powder.

In addition, since welding of the cutting edge is likely to occur, coating treatment is recommended.

STAINLESS STEEL

Stainless steel is excellent in corrosion resistance, it is hard to rust and it is used for many industrial products.

However, there are disadvantages such as hard processability and high price compared to SPCC and SECC.

| Symbol | Tensile Strength Note N/mm² | Elongation % | Note |

| SUS304 | Over 520 | Over 40 | Austenite |

| SUS430 | Over 450 | Over 22 | Ferrite |

ADVICE ON ONE POINT

Because stainless steel has hard processability,

we recommend using a long-life super dry punch without processing oil in punching.

We also recommend coating the punch for forming tooling such as burring.

Knowing the material and characteristics of the material (workpiece),

making appropriate selection of tool

(material, coating etc.), processing conditions (clearance etc.) will lead to improve the quality of the product and reduction of cost.

For the clearance of each material, please refer to “FOR CLEARANCE OF THE CUTTING DIE Vol.6 ”.

PDF Download

-

vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

-

vol.2 LIFE COUNTERMEASURE FOR TOOLING

-

Vol.3 TOOL MAINTENANCE

-

Vol.4 FORMING TOOL

-

Vol.5 MATERIAL FOR TOOLING

-

Vol.6 FOR CLEARANCE OF THE CUTTING DIE

-

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

-

Vol.8 VARIOUS KINDS OF SPECIAL SHAPE

-

Vol.9 PARTS NAME OF STANDARD TOOLING

-

Vol.10 EACH NAMES OF FORMING TOOL

-

Vol.11 MATERIAL PROPERTIES (STEEL)

-

Vol.12 MATERIAL PROPERTIES

-

Vol.13 CALCULATION FORMULAS FREQUENTLY USED IN SHEET METAL

-

Vol.14 HEIGHT ADJUSTMENT FREE TOOL

-

Vol.15 HOW TO DRAW AND READ DRAWINGS

-

Vol.16 HOW TO DRAW AND READ DRAWING (PRACTICAL USE)

-

Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

-

Vol.18 SHAPE INSTRUCTION FOR FORMING TOOLS(2)

-

Vol.19 CODE MANAGEMENT

-

Vol.20 BENDING TECHNICAL INFORMATION

-

Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

-

Vol.22 TECHNICAL COUNSELING FAQ(2) "BURRING FOR THREAD FORM"

-

Vol.23 TECHNICAL COUNSELING FAQ(3) "PITCH OF SINGLE PIERCING"

-

Vol.24 TECHNICAL COUNSELING FAQ(4) "SHEAR OPTIONS"

-

Vol.25 TECHNICAL COUNSELING FAQ(5) "HOLDING MARK"

-

Vol.26 TECHNICAL COUNSELING FAQ(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

-

Vol.27 TECHNICAL COUNSELING FAQ(7) "MATERIAL WARPING PREVENTION DURING"

-

Vol.28 TECHNICAL COUNSELING FAQ(8) "WARPING PREVENTION OF BLANKING OUT"

-

Vol.29 TECHNICAL COUNSELING FAQ(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

-

Vol.30 THE ORDERING GUIDE(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

-

Vol.31 THE ORDERING GUIDE(2) "REFERENCE KEY DIRECTION"

-

Vol.32 THE ORDERING GUIDE(3) "ANGLE INDICATION OF ANGLED TOOL"

-

Vol.33 THE ORDERING GUIDE(4) "SELECT SPECIFICATION OF PUNCH"

-

Vol.34 THE ORDERING GUIDE(5) "DIE SPECIFICATION SELECTION"