Vol.3 TOOL MAINTENANCE

Tool maintenance has a major impact on the quality of the product and tooling life.

We summarized the time and method of appropriate maintenance this time.

GRIND STANDARD TOOL

TIMING OF RE-GRINDING

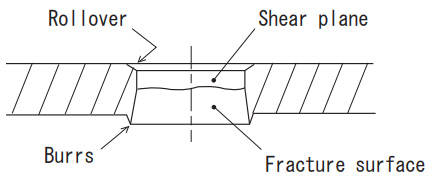

In the case of punching hole, tool and material contact repeatedly,

and as the number of hits increases, tool wear progresses and the following phenomenon appears in theprocessed product.

- ①Increase rollover.

- ②Decreased surface accuracy of the shear surface.

- ③Decreased punching dimensional accuracy.

- ④The product warpage.

- ⑤Increase rollover

Normally, the re-grinding time of punches and dies is determined by the size of burrs. In addition,

it is recommended to regularly observe the condition of the cutting edge (sagging, chipping).

As the wear of the cutting edge progresses, it leads to troubles such as,

- ①Hasten an increasingly wear.

- ②Decreased quality of processed products.

- ③Punch and die will break by increasing of punching load.

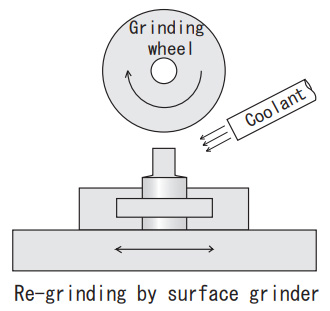

GRIND METHOD

Please always use coolant when grinding.

Grinding with dry or improper coolant may cause cracking or annealing of the cutting edge, which may cause punch and die damage.

After regrinding, remove the polishing burr with a # 600 grinding stone,

remove the coolant, and then apply a lubricant when incorporating it,

because a polishing burr will occur.

Also, adjust the length of the punch or die by the amount of dimensions ground and the punch head or shim.

GENERAL MAINTENANCE

REMOVAL OF ADHESION OF CUTTING EDGE

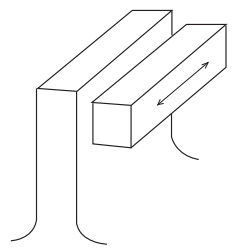

To remove the adhesion of cutting edge, we recommend using an oil stone (#220).

※ When you remove the adhesion, please be careful to keep the cutting edge sharp.

For frequently used punch, we recommend CONIC original coating “SDP” which has an astonishing lifespan.

Remove adhesion using oil stone.

Move parallel to the side surface of punch.

LUBRICATION OF THE SLIDE PART

The sliding portion between the punch body and the guide, we recommend lubrication the oil (such as grease) and cleaning on a regular basis.

The iron powder generated during the punching process attached to the inner diameter of the guide may cause seizure.

KEY MAINTENANCE

It is recommended to replace it regularly as the wear of the turret key (key groove / key pin) has a great effect on the quality of the processed product and the tooling life.

We will take care of the exchange key for tools.

CLEANING UP INSIDE THE TURRET

Even if tool maintenance is carried out sufficiently, if the turret to which the tool is attached contains burrs or foreign substances from slug, it may cause misalignment or galling of the tooling.

When installing the tool, please clean the inside of the turret completely.Attaching a blank die to a turret that is not in use prevents foreign matter from getting inside.

FORMING TOOLING MAINTENANCE

GRIND FORMING TOOLING

Some forming tool has “cutting edge” and it is possible to be sharpened.

※ Depending on the product, reshaping may change the tooling shape.

In addition, HSS tools and replaceable tools are also recommended for frequently used tools.

REPLACEMENT OF URETHANE SPRING OR SPRING

Some forming tools have urethane rubber or spring assembled inside tool for an ejector.

It is recommended to replace it early, as deterioration of the force of the urethane rubber or spring may lead to strip errors and damage to the tool.

Proper maintenance is recommended in order to use the tool for a longer time.

PDF Download

-

vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

-

vol.2 LIFE COUNTERMEASURE FOR TOOLING

-

Vol.3 TOOL MAINTENANCE

-

Vol.4 FORMING TOOL

-

Vol.5 MATERIAL FOR TOOLING

-

Vol.6 FOR CLEARANCE OF THE CUTTING DIE

-

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

-

Vol.8 VARIOUS KINDS OF SPECIAL SHAPE

-

Vol.9 PARTS NAME OF STANDARD TOOLING

-

Vol.10 EACH NAMES OF FORMING TOOL

-

Vol.11 MATERIAL PROPERTIES (STEEL)

-

Vol.12 MATERIAL PROPERTIES

-

Vol.13 CALCULATION FORMULAS FREQUENTLY USED IN SHEET METAL

-

Vol.14 HEIGHT ADJUSTMENT FREE TOOL

-

Vol.15 HOW TO DRAW AND READ DRAWINGS

-

Vol.16 HOW TO DRAW AND READ DRAWING (PRACTICAL USE)

-

Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

-

Vol.18 SHAPE INSTRUCTION FOR FORMING TOOLS(2)

-

Vol.19 CODE MANAGEMENT

-

Vol.20 BENDING TECHNICAL INFORMATION

-

Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

-

Vol.22 TECHNICAL COUNSELING FAQ(2) "BURRING FOR THREAD FORM"

-

Vol.23 TECHNICAL COUNSELING FAQ(3) "PITCH OF SINGLE PIERCING"

-

Vol.24 TECHNICAL COUNSELING FAQ(4) "SHEAR OPTIONS"

-

Vol.25 TECHNICAL COUNSELING FAQ(5) "HOLDING MARK"

-

Vol.26 TECHNICAL COUNSELING FAQ(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

-

Vol.27 TECHNICAL COUNSELING FAQ(7) "MATERIAL WARPING PREVENTION DURING"

-

Vol.28 TECHNICAL COUNSELING FAQ(8) "WARPING PREVENTION OF BLANKING OUT"

-

Vol.29 TECHNICAL COUNSELING FAQ(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

-

Vol.30 THE ORDERING GUIDE(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

-

Vol.31 THE ORDERING GUIDE(2) "REFERENCE KEY DIRECTION"

-

Vol.32 THE ORDERING GUIDE(3) "ANGLE INDICATION OF ANGLED TOOL"

-

Vol.33 THE ORDERING GUIDE(4) "SELECT SPECIFICATION OF PUNCH"

-

Vol.34 THE ORDERING GUIDE(5) "DIE SPECIFICATION SELECTION"