Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

A turret punch press machine is a machine in which a large number of tools having different shapes are arranged in a disk-shaped or fan-shaped turret, NC-controlled table and clamp holding and moving a work (workpiece) are performs punching and forming into place.

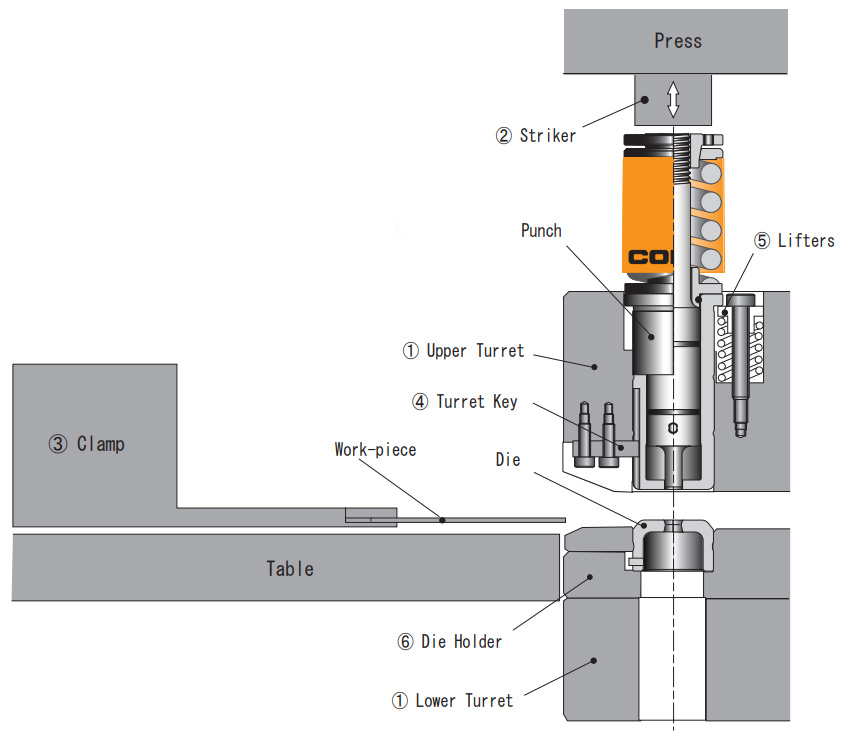

NAMES AND FUNCTIONS OF MAIN PARTS OF THE TURRET PUNCH PRESS MACHINE

① UPPER TURRET / LOWER TURRET

Toolholders which several tooling are set on.

A large number of tools can be mounted, and the turret of these tools is rotated and moved by NC-control and selected.

We recommend that you perform maintenance with a centering fixture etc.

regular basis.

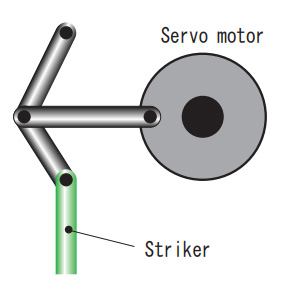

② STRIKER

A slide part that moves up and down with the force of a crank, hydraulic force or servomotor, and transmits the driving force of the press to the tool.Push down the punch (upper) downwards by moving up and down.

③ CLAMP

The part that holds the material.

The specified position of the work is moved to the base of the tool by NC control.

④ TURRET KEY

Positioning the angular shaped tool in the rotational direction.

We recommend that you perform maintenance on a regular basis.

⑤ LIFTERS

Hold the upper tooling and put it up after punching.

⑥ DIE HOLDER

To be set on Lower Turret.

Contamination of foreign matter leads to tool installation failure and can also cause tool breakage.

Be sure to do cleaning when set up the die.

In addition, by attaching a brush die or a roller die to a holder which is not used, it is possible to prevent contamination and prevent scratches on the back side of the work.

FEATURE OF TURRET PUNCH PRESS

- ■Unlike a press machine, the machining position of the tool and material installed in the turret can be controlled by program, and it can be processed with any tool.

For this reason, different products do not need to be changed or can be done in a short time. - ■Although the products are different, it allows to use same tool as long as hole or forming dimensions are same.

- ■It is also possible to produce various types of small quantities in combination with automatic material supply, take-out device, automatic tool changing.

DRIVING METHOD OF TURRET PUNCH PRESS

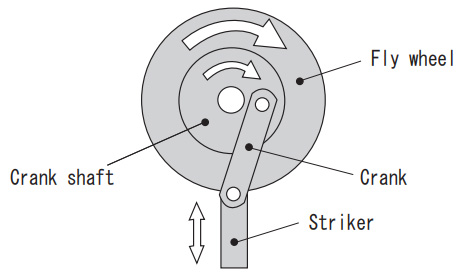

MECHANICAL PRESS(CRANK PRESS)

A system in which the striker is operated by changing the rotational force of the flywheel to a vertical motion via the crankshaft and the crank.

〔 Mechanism of Crank Press 〕

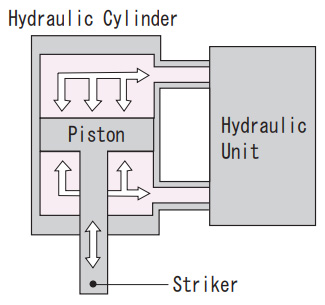

HYDRAULIC PRESS

A system in which a piston is moved up and down by a hydraulic oil pressure to operate a striker.

Features of Hydraulic Press

- ①Bottom dead point is adjustable by Machine program.

- ②Top dead point is also adjustable by machine program which allows to process at high speed.

- ③Less noise comparing to Crank press.

〔 HYDRAULIC PRESS 〕

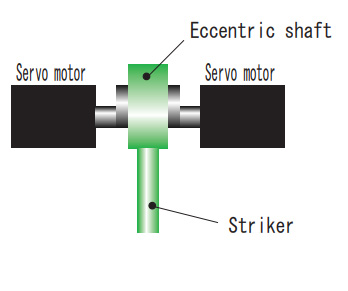

SERVO PRESS

A method of operating the striker by converting the rotational force of the servomotor directly or indirectly to vertical movement via a crank.

Features of Servo Press

- ①High accuracy, high productivity,low noise, energy saving.

- ②It is possible to program of pressure and speed control.

PDF Download

-

vol.1 COUNTERMEASURES FOR SLUG PULLING IN PUNCHING PROCESS

-

vol.2 LIFE COUNTERMEASURE FOR TOOLING

-

Vol.3 TOOL MAINTENANCE

-

Vol.4 FORMING TOOL

-

Vol.5 MATERIAL FOR TOOLING

-

Vol.6 FOR CLEARANCE OF THE CUTTING DIE

-

Vol.7 ABOUT TURRET PUNCH PRESS MACHINE

-

Vol.8 VARIOUS KINDS OF SPECIAL SHAPE

-

Vol.9 PARTS NAME OF STANDARD TOOLING

-

Vol.10 EACH NAMES OF FORMING TOOL

-

Vol.11 MATERIAL PROPERTIES (STEEL)

-

Vol.12 MATERIAL PROPERTIES

-

Vol.13 CALCULATION FORMULAS FREQUENTLY USED IN SHEET METAL

-

Vol.14 HEIGHT ADJUSTMENT FREE TOOL

-

Vol.15 HOW TO DRAW AND READ DRAWINGS

-

Vol.16 HOW TO DRAW AND READ DRAWING (PRACTICAL USE)

-

Vol.17 SHAPE INSTRUCTION FOR FORMING TOOLS(1)

-

Vol.18 SHAPE INSTRUCTION FOR FORMING TOOLS(2)

-

Vol.19 CODE MANAGEMENT

-

Vol.20 BENDING TECHNICAL INFORMATION

-

Vol.21 TECHNICAL COUNSELING FAQ(1) "COUNTERMEASURES FOR GALLING"

-

Vol.22 TECHNICAL COUNSELING FAQ(2) "BURRING FOR THREAD FORM"

-

Vol.23 TECHNICAL COUNSELING FAQ(3) "PITCH OF SINGLE PIERCING"

-

Vol.24 TECHNICAL COUNSELING FAQ(4) "SHEAR OPTIONS"

-

Vol.25 TECHNICAL COUNSELING FAQ(5) "HOLDING MARK"

-

Vol.26 TECHNICAL COUNSELING FAQ(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

-

Vol.27 TECHNICAL COUNSELING FAQ(7) "MATERIAL WARPING PREVENTION DURING"

-

Vol.28 TECHNICAL COUNSELING FAQ(8) "WARPING PREVENTION OF BLANKING OUT"

-

Vol.29 TECHNICAL COUNSELING FAQ(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

-

Vol.30 THE ORDERING GUIDE(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

-

Vol.31 THE ORDERING GUIDE(2) "REFERENCE KEY DIRECTION"

-

Vol.32 THE ORDERING GUIDE(3) "ANGLE INDICATION OF ANGLED TOOL"

-

Vol.33 THE ORDERING GUIDE(4) "SELECT SPECIFICATION OF PUNCH"

-

Vol.34 THE ORDERING GUIDE(5) "DIE SPECIFICATION SELECTION"