Vol.8 Berbagai macam Bentuk spesial

For punching with a turret punch press, various types of special shape tooling are used.

JOINT TOOLING

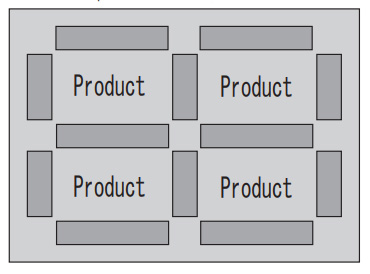

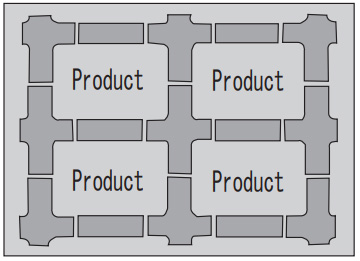

When processing a large number of products with one piece of material (sheet),

a joint type is used to hold the products together.

There are two types of joints: MICRO JOINT and WIRE JOINT.

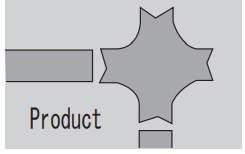

MICRO JOINT

Fix the product to the base material with a small joint and give vibration to the workpiece after processing.

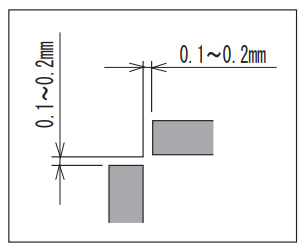

1.Joint of corner part

The outer periphery is removed at square or rectangle,

and a part is connected without cutting off the corner as shown in the right figure.

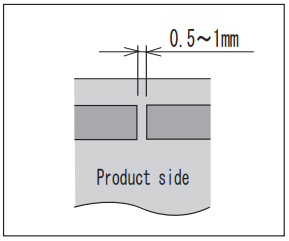

Detail of Joint

Cases of micro joint processing

(Joint of corner part)

2.Joint of straight part

Cases of micro joint processing

(Joint of corner part)

It is recommended to actually process and check with reference to the above dimensions.

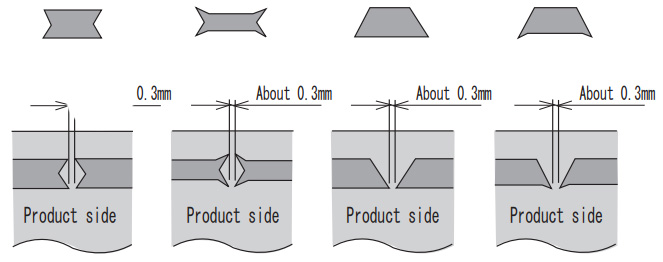

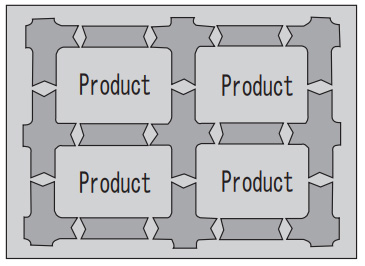

WIRE JOINT

Use a wire joint larger than a micro joint to hold large products together.

Detail of Joint

Cases of micro joint processing

(Joint of corner part)

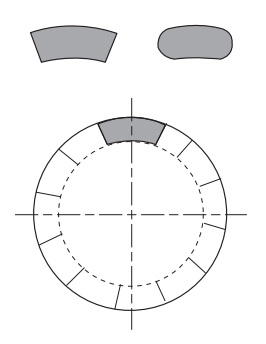

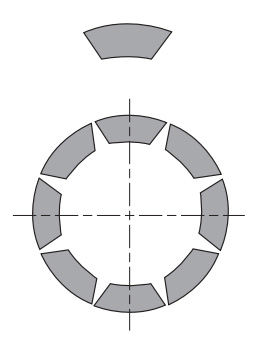

CORNER RADIUS

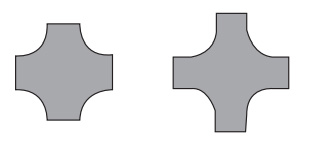

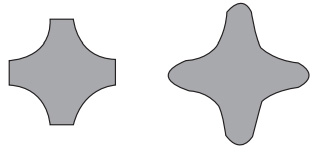

Use the corner radius type (CR type) to Round the corners of the product.

Typical corner radius types are as follows.

| Standard Corner radius tool | Corner radius tool with tangent line | Corner radius with joint |

|

|

|

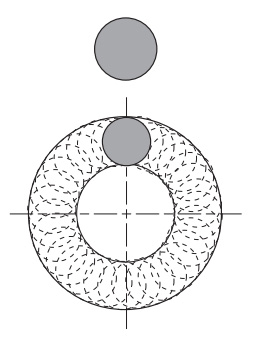

NIBBRING RADIUS TOOLING

There are the following methods for removing holes larger than the size of the punching.

- 1.Slitting processing by Round Nibbling Method

- 2.Slitting processing by Curved tool punching Method

| Round Nibbling Method | Curved tool punching Method | Radius tooling with Joint |

|

|

|

| The punched surface becomes wavy. | The central part pulls out with a round or square shape, and the outer peripherynibble with a rounded shape. | Provide a joint and remove the joint after processing. |

PDF Download

Vol.1 Solusi untuk mencegah slug naik kepermukaan

Vol.2 Solusi untuk meningkatkan masa pakai tool

Vol.3 Pemeliharaan tool

Vol.4 Forming tool

Vol.5 Material yang digunakan untuk memproduksi tool

Vol.6 Die Clearance

Vol.7 Mesin Turret Punch Press

Vol.8 Berbagai macam Bentuk spesial

Vol.9 Nama bagian-bagian tool standar

Vol.10 Forming tool

Vol.11 Jenis material (Baja)

Vol.12 Jenis material (Logam nonferrous)

Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

Vol.14 Tool bebas pengaturan ketinggian

Vol.15 Cara menggambar dan membaca gambar (Dasar)

Vol.16 Cara menggambar dan membaca gambar (Penggunaan praktis)

Vol.17 Instruksi bentuk untuk forming tools(1)

Vol.18 Instruksi bentuk untuk forming tools(2)

Vol.19 Manajemen kode

Vol.20 Informasi teknis bending

Vol.21 T&J konseling teknis(1) "COUNTERMEASURES FOR GALLING"

Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

Vol.23 T&J konseling teknis(3) "PITCH OF SINGLE PIERCING"

Vol.24 T&J konseling teknis(4) "SHEAR OPTIONS"

Vol.25 T&J konseling teknis(5) "HOLDING MARK"

Vol.26 T&J konseling teknis(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

Vol.27 T&J konseling teknis(7) "MATERIAL WARPING PREVENTION DURING"

Vol.28 T&J konseling teknis(8) "WARPING PREVENTION OF BLANKING OUT"

Vol.29 T&J konseling teknis(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

Vol.30 Panduan pemesanan(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

Vol.31 Panduan pemesanan(2) "REFERENCE KEY DIRECTION"

Vol.32 Panduan pemesanan(3) "ANGLE INDICATION OF ANGLED TOOL"

Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

Vol.34 Panduan pemesanan(5) "DIE SPECIFICATION SELECTION"