Vol.14 Tool bebas pengaturan ketinggian

When using a forming tool with a turret punch press, usually,

tool height adjustment is required at the tool or machine side according to the shut height of the press machine.

This time, we summarized the “Height adjustment free tool” that does not require adjustment.

No need height adjustment!

There is no need to adjust the height of the tool when the material thickness changes or the machine changes.

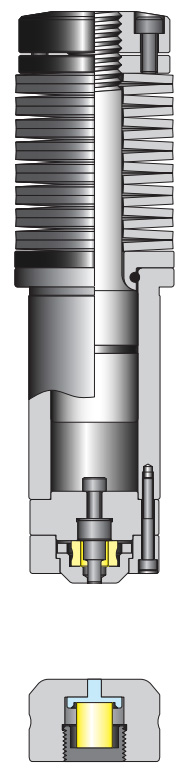

Height adjustment free half punch tool

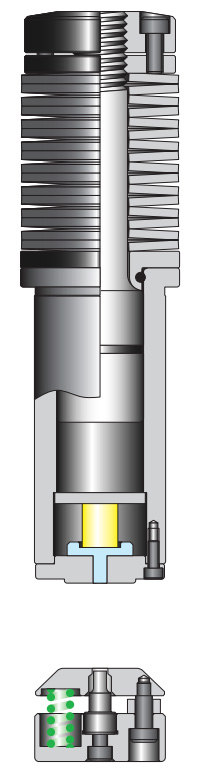

The height adjustment free tool is formed by the compression repulsion force of the spring,

and the spring shrinks and absorbs the stroke portion after the predetermined formed shape is obtained,

so even if the work (plate thickness) changes,

Punch length adjustment (height adjustment) becomes unnecessary.

Forming shape

〔 FORMING UP 〕

〔 FORMING DOWN 〕

Specifications

- ・For Material thickness T= 0.8~1.6 and T= 1.6 ~ 2.3 are available.

- ・The forming height is constant.

| Availability of station size | |

| Thick Turret | 1/2"(A) or 1-1/4"(B) |

| Thin Turret | 1-1/4"(B) |

| MURATA TYPE | C or D |

TOOLING STRUCTURE (NC 1-1/4)

〔 FORMING UP 〕

〔 FORMING DOWN 〕

The "HEIGHT ADJUSTMENT FREE TOOL" has the following advantages because it is not necessary to replace or adjust the tool by changing the material thickness.

- ・The number of tool replacements is reduced and productivity is improved.

- ・It is also possible at night unattended operation with material thickness change.

- ・The process can be started simply by setting the tool in the turret punch press machine,

so it is easy to change the set-up.

In order to form by compression repulsive force of the spring, a station bigger by one size may be required depending on the material thickness and the shape or size.

(Please contact us for more information.)

VARIOUS KINDS OF HEIGHT ADJUSTMENT FREE TOOL

In addition to the half punch, there are the following types of the height adjustment free tool.

| Center point | Emboss (Dimple) | Marking | Chamfering |

|

|

|

|

Other foming shape with adjustment free tools are available.

Please ask our tool sales desk.

PRESSED IN ONE HIT USING SPRING PRESSURE

Tools that use the force of a spring can be processed in one hit,

such as embossing and punching, and embossing and burring.

| Emboss & Pierce in one hit | Emboss & Burring in one hit |

|

|

NOTE

Since the height adjustment free tool absorbs the difference in shut height with a spring,

it can be used even when the bottom dead center position of the machine is unstable.

The spring absorbs the variation of the bottom dead center and a stable formed shape is obtained.

PDF Download

Vol.1 Solusi untuk mencegah slug naik kepermukaan

Vol.2 Solusi untuk meningkatkan masa pakai tool

Vol.3 Pemeliharaan tool

Vol.4 Forming tool

Vol.5 Material yang digunakan untuk memproduksi tool

Vol.6 Die Clearance

Vol.7 Mesin Turret Punch Press

Vol.8 Berbagai macam Bentuk spesial

Vol.9 Nama bagian-bagian tool standar

Vol.10 Forming tool

Vol.11 Jenis material (Baja)

Vol.12 Jenis material (Logam nonferrous)

Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

Vol.14 Tool bebas pengaturan ketinggian

Vol.15 Cara menggambar dan membaca gambar (Dasar)

Vol.16 Cara menggambar dan membaca gambar (Penggunaan praktis)

Vol.17 Instruksi bentuk untuk forming tools(1)

Vol.18 Instruksi bentuk untuk forming tools(2)

Vol.19 Manajemen kode

Vol.20 Informasi teknis bending

Vol.21 T&J konseling teknis(1) "COUNTERMEASURES FOR GALLING"

Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

Vol.23 T&J konseling teknis(3) "PITCH OF SINGLE PIERCING"

Vol.24 T&J konseling teknis(4) "SHEAR OPTIONS"

Vol.25 T&J konseling teknis(5) "HOLDING MARK"

Vol.26 T&J konseling teknis(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

Vol.27 T&J konseling teknis(7) "MATERIAL WARPING PREVENTION DURING"

Vol.28 T&J konseling teknis(8) "WARPING PREVENTION OF BLANKING OUT"

Vol.29 T&J konseling teknis(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

Vol.30 Panduan pemesanan(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

Vol.31 Panduan pemesanan(2) "REFERENCE KEY DIRECTION"

Vol.32 Panduan pemesanan(3) "ANGLE INDICATION OF ANGLED TOOL"

Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

Vol.34 Panduan pemesanan(5) "DIE SPECIFICATION SELECTION"