Vol.31 Panduan pemesanan(2)

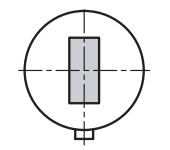

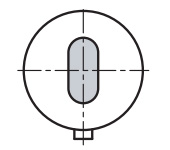

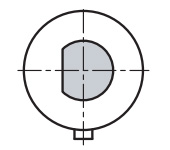

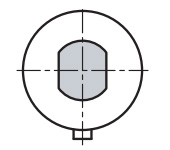

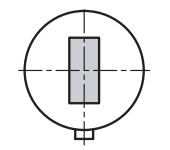

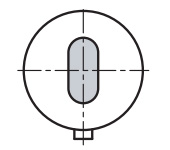

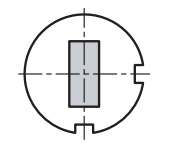

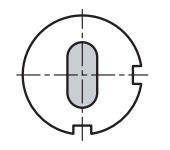

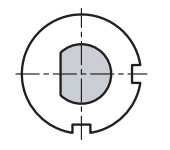

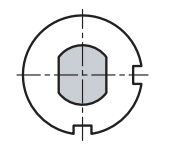

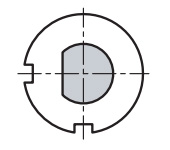

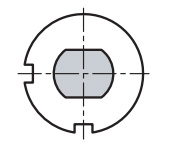

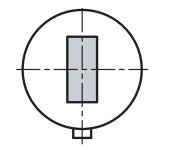

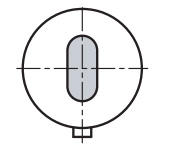

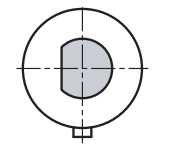

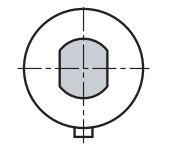

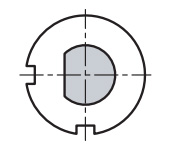

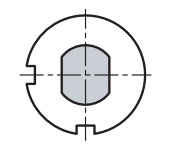

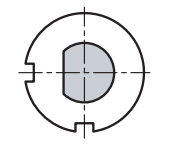

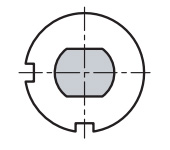

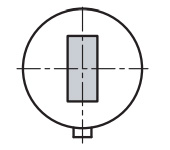

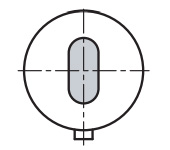

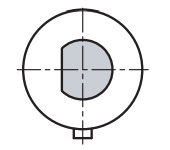

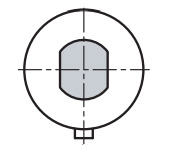

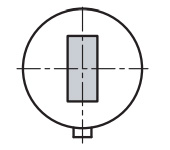

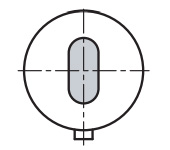

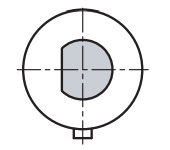

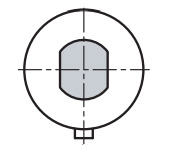

"REFERENCE KEY DIRECTION"

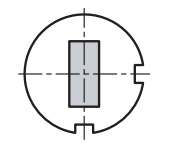

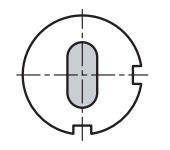

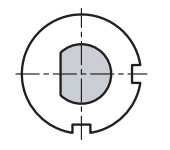

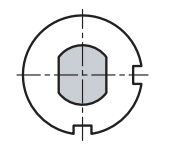

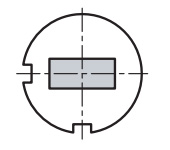

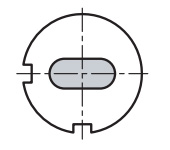

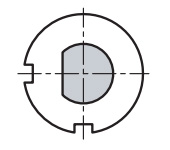

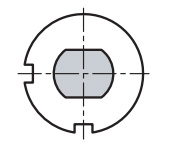

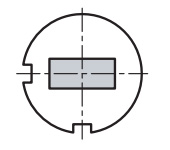

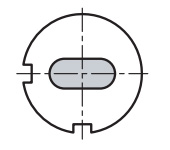

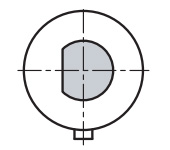

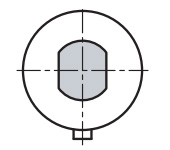

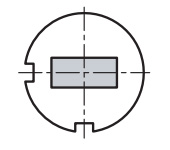

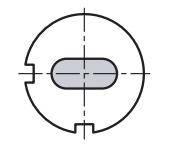

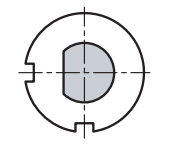

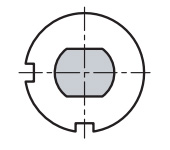

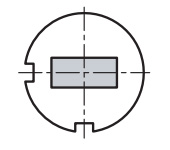

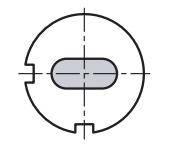

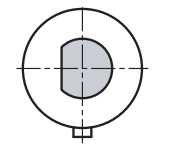

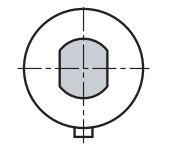

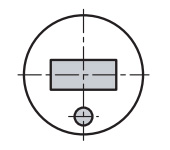

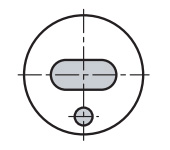

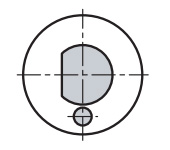

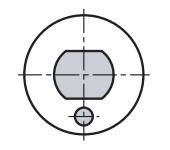

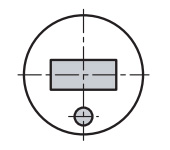

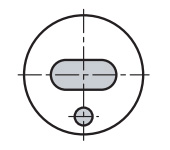

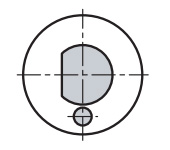

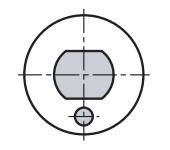

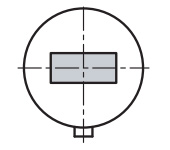

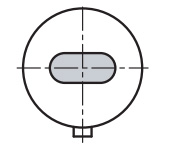

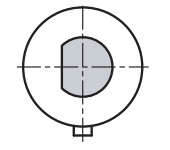

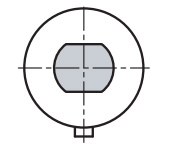

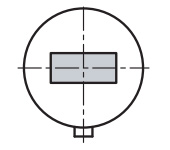

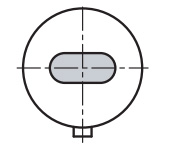

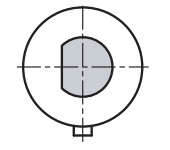

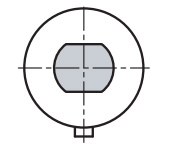

STANDARD EDGE ANGLE RELATIVE TO THE REFERENCE KEY DIRECTION

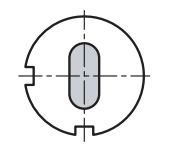

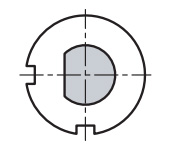

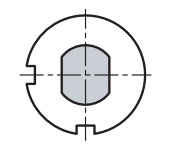

When ordering tool, the blade angle of the standard square shape is as follows unless otherwise specified.

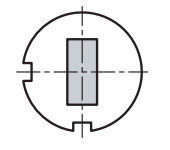

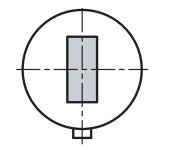

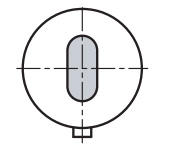

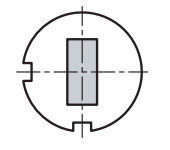

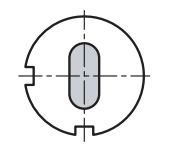

A view of the die from above. The bottom of the figure is the reference key direction.

Thick turret type

| RE | OB | SD | WD | |

|

1/2" 1-1/4" |

|

|

|

|

|

2" |

|

|

|

|

|

3-1/2" 4-1/2" |

|

|

|

|

| RE | OB | |

|

1/2" 1-1/4" |

|

|

|

2" |

|

|

|

3-1/2" 4-1/2" |

|

|

| SD | WD | |

|

1/2" 1-1/4" |

|

|

|

2" |

|

|

|

3-1/2" 4-1/2" |

|

|

Thin turret type

| RE | OB | SD | WD | |

|

1/2" 1-1/4" |

|

|

|

|

|

2" |

|

|

|

|

| 3-1/2" |

|

|

|

|

| RE | OB | |

|

1/2" 1-1/4" |

|

|

|

2" |

|

|

|

3-1/2" 4-1/2" |

|

|

| SD | WD | |

|

1/2" 1-1/4" |

|

|

|

2" |

|

|

|

3-1/2" 4-1/2" |

|

|

Murata 114 type

| RE | OB | SD | WD | |

|

Bst | Jst |

|

|

|

|

| RE | OB | |

|

Bst ~ Jst |

|

|

| SD | WD | |

|

Bst ~ Jst |

|

|

Nisshinbo short type

| RE | OB | SD | WD | |

|

Ast Bst Cst |

|

|

|

|

| RE | OB | |

|

Ast Bst Cst |

|

|

| SD | WD | |

|

Ast Bst Cst |

|

|

Anritsu short type

| RE | OB | SD | WD | |

|

1-1/4" 2" 2-3/4" |

|

|

|

|

| RE | OB | |

|

1-1/4" 2" 2-3/4" |

|

|

| SD | WD | |

|

1-1/4" 2" 2-3/4" |

|

|

ADVICE ON ONE POINT

- 1. Depending on the machine and tool size, the clamp direction and reference key direction may differ. Also, the key direction of punch and die may change 180°.

-

2.

When ordering a tool with an angle, please specify the edge angle.

(The ordering method is published in Technical Information Vol.32.) - 3. When ordering a special shape tool, please indicate the reference key direction as seen from above the die.

Vol.1 Solusi untuk mencegah slug naik kepermukaan

Vol.2 Solusi untuk meningkatkan masa pakai tool

Vol.3 Pemeliharaan tool

Vol.4 Forming tool

Vol.5 Material yang digunakan untuk memproduksi tool

Vol.6 Die Clearance

Vol.7 Mesin Turret Punch Press

Vol.8 Berbagai macam Bentuk spesial

Vol.9 Nama bagian-bagian tool standar

Vol.10 Forming tool

Vol.11 Jenis material (Baja)

Vol.12 Jenis material (Logam nonferrous)

Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

Vol.14 Tool bebas pengaturan ketinggian

Vol.15 Cara menggambar dan membaca gambar (Dasar)

Vol.16 Cara menggambar dan membaca gambar (Penggunaan praktis)

Vol.17 Instruksi bentuk untuk forming tools(1)

Vol.18 Instruksi bentuk untuk forming tools(2)

Vol.19 Manajemen kode

Vol.20 Informasi teknis bending

Vol.21 T&J konseling teknis(1) "COUNTERMEASURES FOR GALLING"

Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

Vol.23 T&J konseling teknis(3) "PITCH OF SINGLE PIERCING"

Vol.24 T&J konseling teknis(4) "SHEAR OPTIONS"

Vol.25 T&J konseling teknis(5) "HOLDING MARK"

Vol.26 T&J konseling teknis(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

Vol.27 T&J konseling teknis(7) "MATERIAL WARPING PREVENTION DURING"

Vol.28 T&J konseling teknis(8) "WARPING PREVENTION OF BLANKING OUT"

Vol.29 T&J konseling teknis(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

Vol.30 Panduan pemesanan(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

Vol.31 Panduan pemesanan(2) "REFERENCE KEY DIRECTION"

Vol.32 Panduan pemesanan(3) "ANGLE INDICATION OF ANGLED TOOL"

Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

Vol.34 Panduan pemesanan(5) "DIE SPECIFICATION SELECTION"