Vol.5 Material yang digunakan untuk memproduksi tool

Selection of tool material (Type of material) is very important in terms of the quality of the processed product and the tool life (processing cost).

This time, we summarized the typical material for tooling.

MATERIAL OF PUNCH

We use the following material for punch body.

- ・D2(SKD)

- ・M2(SKH)

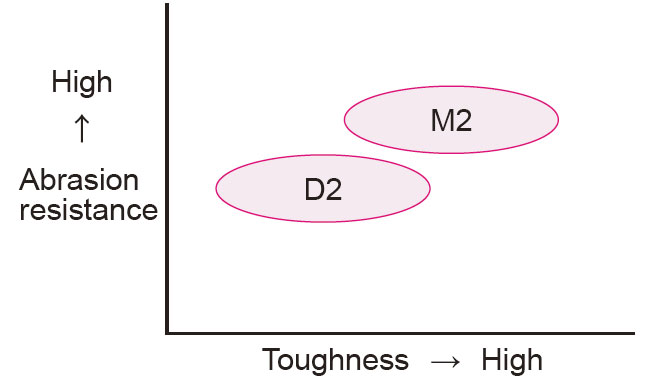

Fig.1 Material properties of the punch

Characteristics of each steel

D2 (SKD)

It is a typical tool steel for sheet metal processing which is excellent in mechanical properties and heat treatment characteristics.

We adopt Super-subzero treatment to further improve wear resistance.

M2 (SKH)

It is one of the most widely used materials among M2.

Compared to D2, it is a material excellent in abrasion resistance, impact resistance and toughness.

It is suitable materials such as stainless steel and a large amount production.

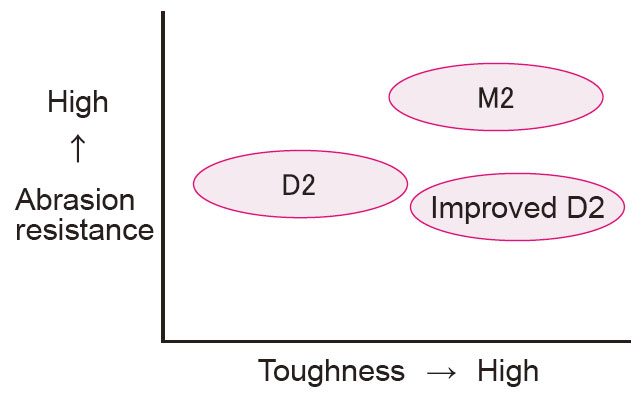

MATERIAL OF DIE

We use the following material for die.

- ・Improved D2

- ・M2(SKH)

Characteristics of steel

Improved D2

A material with improved toughness and chipping resistance by refining carbides. It has toughness equal to or higher than that of M2.

HOW TO SELECT MATERIAL

Selection of the material of the tool is done by processing conditions (such as the material of sheet metal, the number of hits and the accuracy of product).

The guides of selection are as follows.

| GUIDE FOR SELECTING D2 | GUIDE FOR SELECTING M2 |

|

|

In case of large number of production or difficult-working materials, it is recommended to use in combination with super-dry punch or coating process tools.

Not only the insufficient strength of the tool but also other factors

(such as sludge rise, misalignment of the turret,insufficient mounting of the tool,etc.)

can be considered as the cause of the breakage of the tool.

We recommend that you select the material after carefully investigating the cause of the damage.

(See our PANDUAN TEKNIS “2-2) Life countermeasure for tooling” for more detail about SDP.)

OTHER MATERIAL FOR TOOLING

CARBON STEELS FOR MACHINE STRUCTURAL MATERIAL

It is one of the representative steel types of metal materials.

In the tool, it is used for part that is not processed directly on the material.

(Tool head, retainer collar etc.)

CHROMIUM MOLYBDENUM STEEL(SCM)

It is used for parts that require middle strength. (Guide, ejector of forming tool etc.)

CARBON TOOL STEEL(SK)

It is used for parts that require relatively high hardness. (Key-pin, ejector of forming tool etc.)

ALLOY TOOL STEEL(SKS)

Used for a part this needs equal hardness as D2 steel. (Pin holder etc.)

Vol.1 Solusi untuk mencegah slug naik kepermukaan

Vol.2 Solusi untuk meningkatkan masa pakai tool

Vol.3 Pemeliharaan tool

Vol.4 Forming tool

Vol.5 Material yang digunakan untuk memproduksi tool

Vol.6 Die Clearance

Vol.7 Mesin Turret Punch Press

Vol.8 Berbagai macam Bentuk spesial

Vol.9 Nama bagian-bagian tool standar

Vol.10 Forming tool

Vol.11 Jenis material (Baja)

Vol.12 Jenis material (Logam nonferrous)

Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

Vol.14 Tool bebas pengaturan ketinggian

Vol.15 Cara menggambar dan membaca gambar (Dasar)

Vol.16 Cara menggambar dan membaca gambar (Penggunaan praktis)

Vol.17 Instruksi bentuk untuk forming tools(1)

Vol.18 Instruksi bentuk untuk forming tools(2)

Vol.19 Manajemen kode

Vol.20 Informasi teknis bending

Vol.21 T&J konseling teknis(1) "COUNTERMEASURES FOR GALLING"

Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

Vol.23 T&J konseling teknis(3) "PITCH OF SINGLE PIERCING"

Vol.24 T&J konseling teknis(4) "SHEAR OPTIONS"

Vol.25 T&J konseling teknis(5) "HOLDING MARK"

Vol.26 T&J konseling teknis(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

Vol.27 T&J konseling teknis(7) "MATERIAL WARPING PREVENTION DURING"

Vol.28 T&J konseling teknis(8) "WARPING PREVENTION OF BLANKING OUT"

Vol.29 T&J konseling teknis(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

Vol.30 Panduan pemesanan(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

Vol.31 Panduan pemesanan(2) "REFERENCE KEY DIRECTION"

Vol.32 Panduan pemesanan(3) "ANGLE INDICATION OF ANGLED TOOL"

Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

Vol.34 Panduan pemesanan(5) "DIE SPECIFICATION SELECTION"