Vol.10 Forming tool

When forming processing by a turret punch press, adjustments different from punching is required.

This time, We summarized the part names and functions of forming tool and how to adjust the tool.

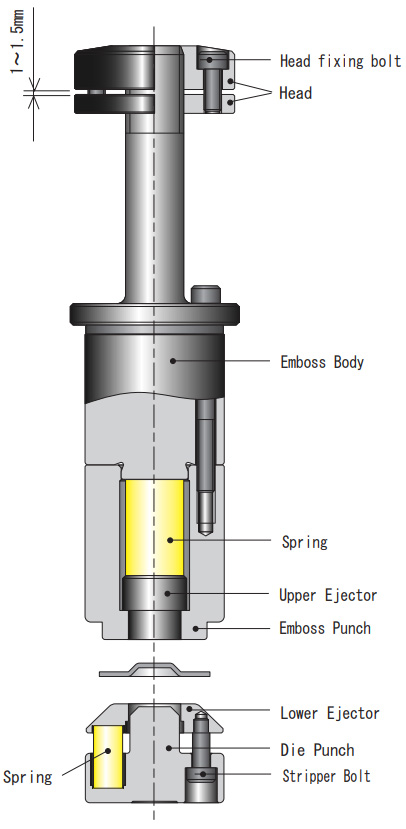

UPWARD FORMING TOOL

Upward forming is a process that forms from the down side of the workpiece upward.

EACH PART NAMES AND FUNCTIONS OF UPPER TOOLING (PUNCH SET)

① EMBOSS PUNCH

A part that directly forms a workpiece.

② EMBOSS BODY

A part that holds the emboss punch.

③ UPPER EJECTOR

A part to eject formed shape after processing.

In addition, there are also cases in which the workpiece is formed as an aid.

④ HEAD

The part that directly receives the force of the striker and transmits it to the embossed body and punch.

Also, adjust the punch length to determine the rising height of the forming shape.

How to adjust the punch length. (Height Adjustment)

- 1.Loosen the head fixing bolts.

- 2.Rotate the head and adjust length of punch.

(Clearance between upper head and lower head keep 1mm to 1.5mm.) - 3.Fasten the head fixing bolts equally.

EACH PART NAMES AND FUNCTIONS OF LOWER TOOLING (DIE SET)

⑤ DIE PUNCH

A part that directly forms a workpiece.

⑥ LOWER EJECTOR, SPRING

During processing, hold the workpiece, and after processing,

push up the lower ejector by the force of the spring and pull the workpiece away from the die punch.

⑦ STRIPPER BOLT

A part that connects the die punch and the lower die ejector.

Height of forming tool die tends to be higher than standard tool die. For that reason, it scratches a material or forming part would be hit to Upper Turret. Appropriate processing method and programing are needed.

<Reference> Adjustment amount of head

| Screw size and pitch | Adjustment amount per 1/4 rotation |

| M12×P1.25 | 0.3mm |

| M20×P1.5 | 0.4mm |

| M30×P2.0 | 0.5mm |

| M40×P2.0 | 0.5mm |

〔 TOOLING STRUCTURE (NC 1-1/4) 〕

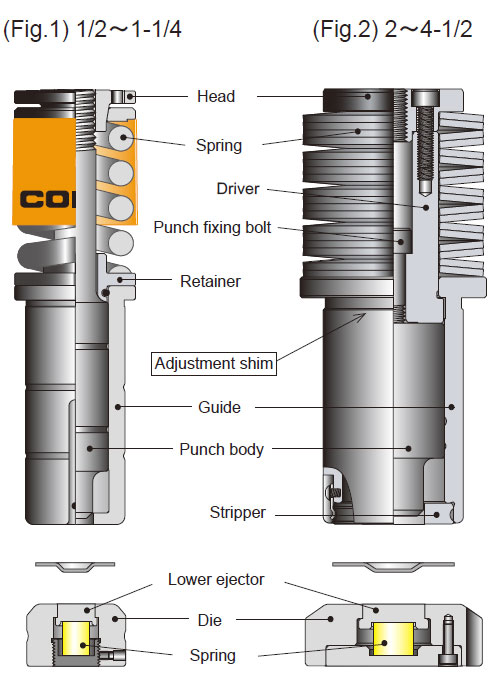

DOWNWARD FORMING TOOL

Downward forming is a process that forms from the top of the workpiece downward.

EACH PART NAMES AND FUNCTIONS OF UPPER TOOLING (PUNCH SET)

For the part names and functions of the upper tooling, refer to “PART NAMES OF THE STANDARD TOOLING” (Vol. 9).

The method of adjusting the punch length depends on the tool structure.

METHOD OF ADJUSTING PUNCH LENGTH FOR Fig.1

- 1.Attach cap screw to the two bolt holes and tighten evenly.

- 2.Rotate the head by the belt wrench and adjust the punch length.

- 3.Remove the cap screw.

Adjusting punch length for Fig.2

- 1.Loosen a punch fixing bolt.

- 2.Remove a punch body from a guide and put shims on between the punch and driver.

- 3.Install the punch body and fasten the punch fixing bolt.

NOTE

When making fine adjustment, first adjust with die-shim,

remove the die shim after the adjustment is finished,

you can easily adjust by using the same thickness punch shim to punch side.

EACH PART NAMES AND FUNCTIONS OF LOWER TOOLING (DIE SET)

① DIE

A part to form a material directly.

② LOWER EJECTOR

Push up a forming after processing.

③ SPRING

Push up the ejector.

IMPORTANT NOTICE

- 1.Use in a predetermined machining conditions.

Excessive load may be applied to the tool and damage may be caused if the punch overall length is increased for use other than the specified plate thickness (material) or to raise the rise higher than the predetermined tooling dimension. - 2.Even for presses of the same model, the shut height differs for each machine, so please adjust the appropriate punch length.

- ※At shipment from factory, we set the punch length shorter for safety.

PDF Download

Vol.1 Solusi untuk mencegah slug naik kepermukaan

Vol.2 Solusi untuk meningkatkan masa pakai tool

Vol.3 Pemeliharaan tool

Vol.4 Forming tool

Vol.5 Material yang digunakan untuk memproduksi tool

Vol.6 Die Clearance

Vol.7 Mesin Turret Punch Press

Vol.8 Berbagai macam Bentuk spesial

Vol.9 Nama bagian-bagian tool standar

Vol.10 Forming tool

Vol.11 Jenis material (Baja)

Vol.12 Jenis material (Logam nonferrous)

Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

Vol.14 Tool bebas pengaturan ketinggian

Vol.15 Cara menggambar dan membaca gambar (Dasar)

Vol.16 Cara menggambar dan membaca gambar (Penggunaan praktis)

Vol.17 Instruksi bentuk untuk forming tools(1)

Vol.18 Instruksi bentuk untuk forming tools(2)

Vol.19 Manajemen kode

Vol.20 Informasi teknis bending

Vol.21 T&J konseling teknis(1) "COUNTERMEASURES FOR GALLING"

Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

Vol.23 T&J konseling teknis(3) "PITCH OF SINGLE PIERCING"

Vol.24 T&J konseling teknis(4) "SHEAR OPTIONS"

Vol.25 T&J konseling teknis(5) "HOLDING MARK"

Vol.26 T&J konseling teknis(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

Vol.27 T&J konseling teknis(7) "MATERIAL WARPING PREVENTION DURING"

Vol.28 T&J konseling teknis(8) "WARPING PREVENTION OF BLANKING OUT"

Vol.29 T&J konseling teknis(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

Vol.30 Panduan pemesanan(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

Vol.31 Panduan pemesanan(2) "REFERENCE KEY DIRECTION"

Vol.32 Panduan pemesanan(3) "ANGLE INDICATION OF ANGLED TOOL"

Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

Vol.34 Panduan pemesanan(5) "DIE SPECIFICATION SELECTION"