Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

This time, we summarized a calculation formula that is frequently used in sheet metal,

including the calculation of tonnage.

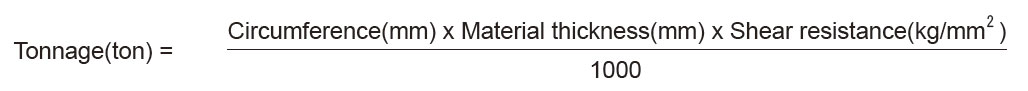

TONNAGE CALCULATION

In the punch press machine, the allowable tonnage depending on the machine.

Use the calculation formula below to prevent from over tonnage.

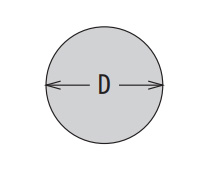

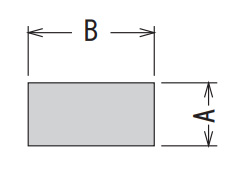

Circumference

| Round | Shaped |

| Diameter x 3.14 | (Length dimension + Width dimension) x 2 |

|

|

| Circumference = D x 3.14 | Circumference = (A + B) x 2 |

Shear resistance by material

| Material | Shear resistance (kg/mm²) |

| Mild Steel | 400 |

| SS400 | 450 |

| Stainless Steel | 600 |

| Aluminum | 200 |

| Copper | 300 |

| Brass | 400 |

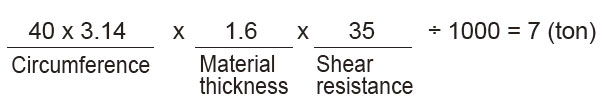

Calculation example

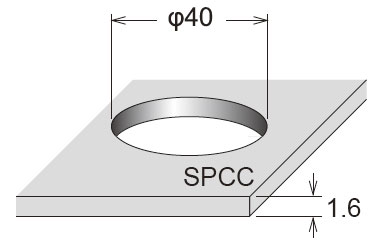

The tonnage when piercing Φ40 to Mild Steel T=1.6mm.

If you do not know the shear resistance, please use about 80% of the shear resistance = tensile strength as a standard.

ADVICE ON ONE POINT

If the tonnage exceeds the allowable tonnage of the machine,

reduce the tonnage by the following method.

- 1.Put shear angle on punch edge. (Allows you to reduce tonnages around 10 to 50% by shear angle.)

- 2.Piercing several times. (Reducing tonnages by piercing several times)

- 3.When using cluster tooling, the tonnages can be reduced by making a difference in length of punch that makes same effect as shear angle.

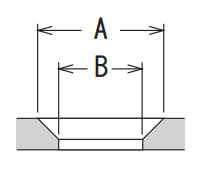

MAKE A SELECTION OF TOOL STATION

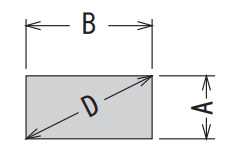

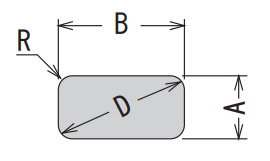

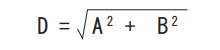

Calculation of the diameter (diagonal dimension) of the cutting edge circumscribed circle is required to select the tool station.

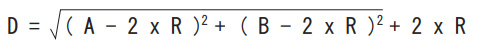

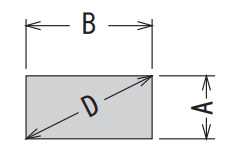

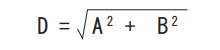

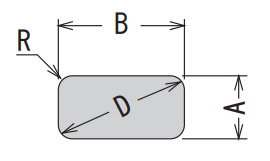

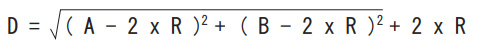

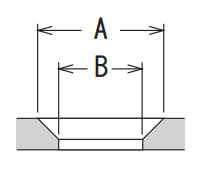

Calculation of diameter (diagonal dimension) of cutting edge circumscribed circle

| Rectanglar shape | Rectanglar shape with radius |

|

|

|

|

| Rectanglar shape |

|

|

| Rectanglar shape with radius |

|

|

ADVICE ON ONE POINT

Normally, the size of the tool station is determined by calculating the dimension of the cutting edge circumscribing circle using the above formula and then comparing it with the turret layout.

However, when processing thick materials, it is necessary to increase the station size by one size to prevent from miss stripping.

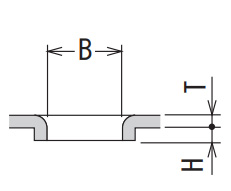

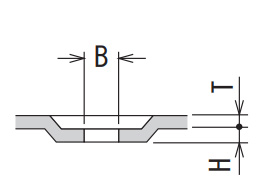

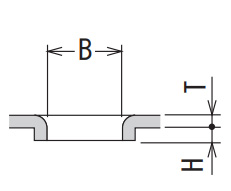

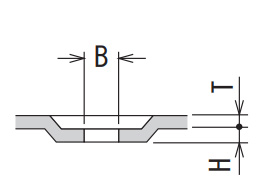

CALCULATING PRE-HOLE DIMENSION FOR FORMING

When forming processing, pre-holes may be processed as pre-processing.

In that case, please calculate pre-holes referring to the following calculation formula.

Calculating pre-hole dimension for forming (Reference value for SPCC)

| Chamfering | Burring | Burring for tapping | Emboss | ||

| Size | Inner Dia. | Pre-hole | |||

|

|

M2.6 | φ2.1 | φ1.2 |

|

| M3 | φ2.6 | φ1.5 | |||

| M4 | φ3.4 | φ2.0 | |||

| M5 | φ4.3 | φ2.4 | |||

| M6 | φ5.1 | φ2.8 | |||

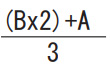

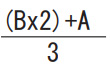

Pre-hole =

|

Pre-hole = D+1.8xT-2xH |

Other dimension, Pre-hole = 0.53 x D + 0.1 |

Other dimension, D-(0.6-0.16xT)xH |

||

| Chamfering | Burring | Emboss |

|

|

|

| Burring for tapping | ||

| Size | Inner Dia | Pre-hole |

| M2.6 | φ2.1 | φ1.2 |

| M3 | φ2.6 | φ1.5 |

| M4 | φ3.4 | φ2.0 |

| M5 | φ4.3 | φ2.4 |

| M6 | φ5.1 | φ2.8 |

| Chamfering | Burring | Emboss |

Pre-hole =

|

Pre-hole = D+1.8xT-2xH |

Other dimension, D-(0.6-0.16xT)xH |

| Burring for tapping | ||

| Size | Inner Dia | Pre-hole |

|

Other dimension, Pre-hole = 0.53 x D + 0.1 |

||

ADVICE ON ONE POINT

Although forming shape is same, pre-hole dimension would be different depending on material.

It is recommended that you try trial machining with reference to the above equation to obtain proper pre-hole dimension.

Vol.1 Solusi untuk mencegah slug naik kepermukaan

Vol.2 Solusi untuk meningkatkan masa pakai tool

Vol.3 Pemeliharaan tool

Vol.4 Forming tool

Vol.5 Material yang digunakan untuk memproduksi tool

Vol.6 Die Clearance

Vol.7 Mesin Turret Punch Press

Vol.8 Berbagai macam Bentuk spesial

Vol.9 Nama bagian-bagian tool standar

Vol.10 Forming tool

Vol.11 Jenis material (Baja)

Vol.12 Jenis material (Logam nonferrous)

Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

Vol.14 Tool bebas pengaturan ketinggian

Vol.15 Cara menggambar dan membaca gambar (Dasar)

Vol.16 Cara menggambar dan membaca gambar (Penggunaan praktis)

Vol.17 Instruksi bentuk untuk forming tools(1)

Vol.18 Instruksi bentuk untuk forming tools(2)

Vol.19 Manajemen kode

Vol.20 Informasi teknis bending

Vol.21 T&J konseling teknis(1) "COUNTERMEASURES FOR GALLING"

Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

Vol.23 T&J konseling teknis(3) "PITCH OF SINGLE PIERCING"

Vol.24 T&J konseling teknis(4) "SHEAR OPTIONS"

Vol.25 T&J konseling teknis(5) "HOLDING MARK"

Vol.26 T&J konseling teknis(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

Vol.27 T&J konseling teknis(7) "MATERIAL WARPING PREVENTION DURING"

Vol.28 T&J konseling teknis(8) "WARPING PREVENTION OF BLANKING OUT"

Vol.29 T&J konseling teknis(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

Vol.30 Panduan pemesanan(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

Vol.31 Panduan pemesanan(2) "REFERENCE KEY DIRECTION"

Vol.32 Panduan pemesanan(3) "ANGLE INDICATION OF ANGLED TOOL"

Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

Vol.34 Panduan pemesanan(5) "DIE SPECIFICATION SELECTION"