Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

SELECT SPECIFICATION OF PUNCH

When ordering punches, please select and refer to the following specifications.

Selection of punch material and surface treatment

| Grade | Specification | Characteristec |

|

High performance

performance |

Super Dry Punch (SDP) |

Excellent durability is realized by the W effect of the “super-hard film and permeation layer to punch base material” on the surface. Suitable for dry processing without press oil. Excellent effect on difficult-to-process materials such as stainless steel. Currently, Only the following shapes are supported.

|

|

Heavy Duty Punch (HDP) |

Coating with excellent heat resistance. The coating is difficult to peel off even with heat generated continuously. |

|

|

Conic Long Life Punch (CLP) |

Suitable for a wide range of work materials such as high corrosion resistant hot-dip galvanized steel sheets, mainly Mild Steel. | |

|

Conic Hard Punch (CHP) |

It has been made “Special Treatment” to the punch cutting edge. This is a low-cost tool that is effective not only for cutting edge wear but also for preventing galling. |

|

|

High Speed Steel (HSS) |

Supports a wide range from Aluminum to Mild steel and Stainless steel. Harder than D2 and has excellent durability. |

|

| D2 | The most basic type of tool material. It is a basic tool that excels in cost performance and adapts to all workpieces. |

Selection of punch shear angle

The shear angle of the punch is effective for reducing punching load, preventing slug pulling,

and silencing.

When ordering, please indicate the presence and type of shear angle.

| Shear option | Characteristec | |

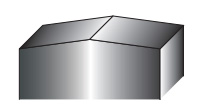

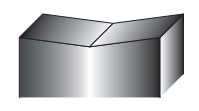

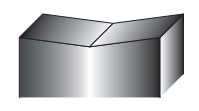

| Roof top shear |

|

Best shear for punching with maximum tonnages. CONIC standard angle of shear is 2°or 5°. Easy to sharpened up. |

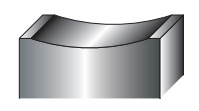

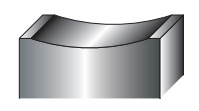

| Concave shear |

|

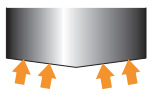

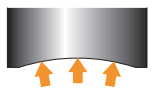

Best shear for slitting and nibbling because it inverts stresses. More susceptible to breakage because of a sharp focal point for stresses when piercing thick material. Defficult to sharpen without dedicated jigs. 〔 Resistant direction to punch tip 〕 In case of roof top shear

In case of concave shear

|

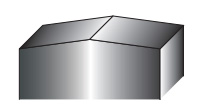

| Inverted shear |

|

|

| Shear option | |

| Roof top shear |

|

| Characteristec | |

|

Best shear for punching with maximum tonnages. CONIC standard angle of shear is 2°or 5°. Easy to sharpened up. |

|

| Shear option | |

| Concave shear |

|

| Inverted shear |

|

| Characteristec | |

|

Best shear for slitting and nibbling because it inverts stresses. More susceptible to breakage because of a sharp focal point for stresses when piercing thick material. Defficult to sharpen without dedicated jigs. 〔 Resistant direction to punch tip 〕 In case of roof top shear

In case of concave shear

|

|

-

※

In general, small diameter punches do not have a shear angle because the removal load is small.

Also, there is no shear angle for the blank type (if the slug is a product) because the blank is deformed.

For details, see Technical Information Vol.24.

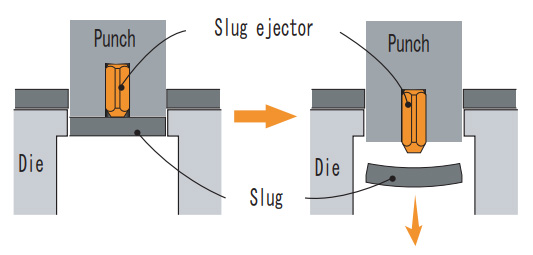

Slug ejector

Slug ejector is effective in preventing slug pulling.

The round shape is φ4 or more, and the standard square shape is attached to the punch edge of 6 width or more as standard in our company.

In addition, if you give us an instruction, we will attach it to a standard square blade with a width of 6 or more for free.

When processing thick plates with small-diameter and narrow punches, the slug ejector holes may cause punch damage.

In that case, please indicate“No slug ejector”.

〔 Fig. 1 Pushing slug mechanism by slug ejector 〕

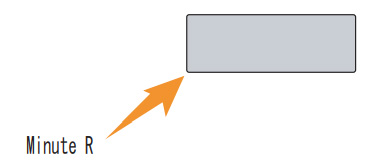

Minutes corner "R" on punch tip

As a measure to prevent chipping at the blade edge,

we have added a small R of about R0.2 to the four corners of square and rectangle punches.

If you don’t need it, please let us know.

〔 Fig.2 Minutes corner R on the punch tip of

SQ and RE shape punches. 〕

Coating treatment

In addition to Super Dry Punch (SDP), Heavy Duty Punch (HDP), Conic Long Life Punch (CLP),

and Conic Hard Punch (CHP), you can also select various “coating treatments” that improve the life of the tool.

| Coating option | Characteristec |

| Tuff coat |

Salt bath nitriding treatment to our premium high speed steel. It shows high performance preventing from peeling off. Hardness of surface is Hv900 - 1,100. |

| TiCN coat |

Ticn treatment to our premium high speed steel. Hardness of surface is Hv2,700 - 3,000 which is harder than Tin coating. |

| TiN coat |

Tin treatment for our premium high speed steel. Good for mild steel. Hardness of surface is Hv2,000 - 2,500. |

| CrN coat |

CrN treatment to our premium high speed steel. Good for aluminum. Hardness of surface is Hv1,700 - 2,100. |

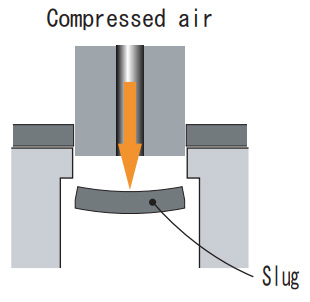

Air-hole specification

From the air hole in the center position of punch body,

compressed air is blown directly onto the slug to forcibly drop the slug.

〔 Fig.3 Air-hole spec. 〕

Vol.1 Solusi untuk mencegah slug naik kepermukaan

Vol.2 Solusi untuk meningkatkan masa pakai tool

Vol.3 Pemeliharaan tool

Vol.4 Forming tool

Vol.5 Material yang digunakan untuk memproduksi tool

Vol.6 Die Clearance

Vol.7 Mesin Turret Punch Press

Vol.8 Berbagai macam Bentuk spesial

Vol.9 Nama bagian-bagian tool standar

Vol.10 Forming tool

Vol.11 Jenis material (Baja)

Vol.12 Jenis material (Logam nonferrous)

Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

Vol.14 Tool bebas pengaturan ketinggian

Vol.15 Cara menggambar dan membaca gambar (Dasar)

Vol.16 Cara menggambar dan membaca gambar (Penggunaan praktis)

Vol.17 Instruksi bentuk untuk forming tools(1)

Vol.18 Instruksi bentuk untuk forming tools(2)

Vol.19 Manajemen kode

Vol.20 Informasi teknis bending

Vol.21 T&J konseling teknis(1) "COUNTERMEASURES FOR GALLING"

Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

Vol.23 T&J konseling teknis(3) "PITCH OF SINGLE PIERCING"

Vol.24 T&J konseling teknis(4) "SHEAR OPTIONS"

Vol.25 T&J konseling teknis(5) "HOLDING MARK"

Vol.26 T&J konseling teknis(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

Vol.27 T&J konseling teknis(7) "MATERIAL WARPING PREVENTION DURING"

Vol.28 T&J konseling teknis(8) "WARPING PREVENTION OF BLANKING OUT"

Vol.29 T&J konseling teknis(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

Vol.30 Panduan pemesanan(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

Vol.31 Panduan pemesanan(2) "REFERENCE KEY DIRECTION"

Vol.32 Panduan pemesanan(3) "ANGLE INDICATION OF ANGLED TOOL"

Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

Vol.34 Panduan pemesanan(5) "DIE SPECIFICATION SELECTION"