Vol.27 T&J konseling teknis(7)

"MATERIAL WARPING PREVENTION DURING"

Here are some of the questions we have contacted the Tool Consultation.

MATERIAL WARPING PREVENTION DURING PUNCHING

Are there any measures?

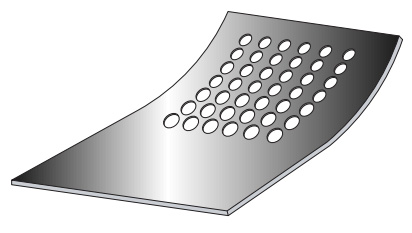

When a large number of holes are punched using a turret punch press, the material (workpiece) may warp,and making it impossible to process or not be a product. (See Fig.1)

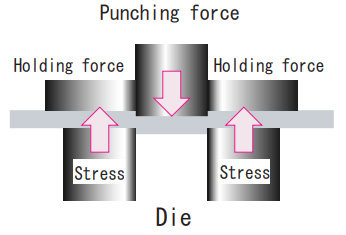

This is because when the punch out the workpiece,

bending stress is generated at the same time as the shearing force,

and internal stress is generated due to the plate pressing pressure of the tool.

After that, when the material is released from the plate press, the board warps due to the stress inside the material. (See Fig.2)

Fig.1 The sheetmetal distorted after punching

As a countermeasure…

-

1.

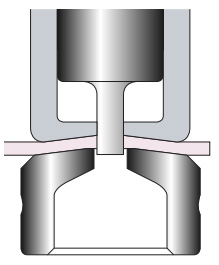

A tapering process is applied to the material pressing surfaces of the guide or the stripper and the die to apply a stress in the direction opposite to the warpage to flatten the work. (see Fig.3)

Usually, a taper of 1 degree to 2 degree is added to one side or all around so that the die side is convex and the guide or the stripper side is concave.

Fig.2 Punching force and stress

Fig.3 Put taper on a stripper and die

Put taper all around

Put taper on one side

-

2.

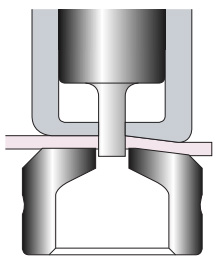

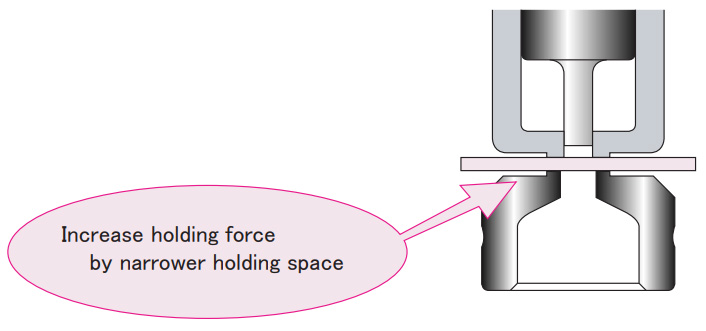

By strengthening the "plate holding force" to hold the material, the bending stress generated on the material is suppressed to reduce the warpage.

As a way to increase the plate holding force,

- a ) Increase the force of the upper spring by raising the station.

- b ) There is a way to increase the surface pressure around the punch by reducing the holding area of either or both of the guide or die.(see Fig.4)

Fig.4 Increase holding force

-

3.

Keep the edge of the punch and die sharp at all times.

Wear on the cutting edge increases shear resistance and causes warpage.

Please regrinding the cutting edge early and keep the cutting edge sharp at all times. -

4.

Punching with proper clearance.

An excessively large clearance increases the bending stress of the punching process.

Warpage can be reduced by proper clearance or slightly smaller clearance.

-

5.

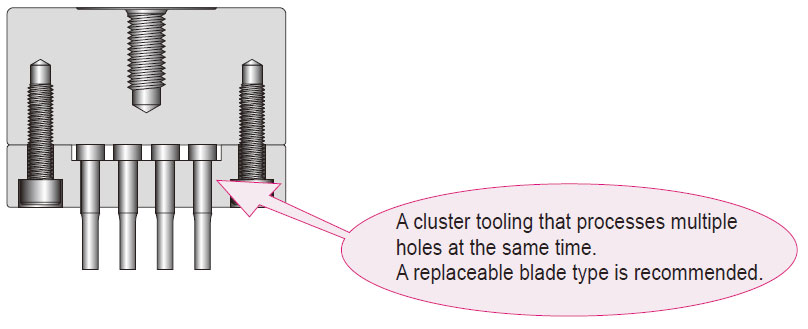

Use cluster tool.

In case of punching process with many same dimensions,

warpage will be less if multiple holes are formed at one process with cluster tool than single punching.(See Fig.5)

Fig.5 Cluster tooling

Vol.1 Solusi untuk mencegah slug naik kepermukaan

Vol.2 Solusi untuk meningkatkan masa pakai tool

Vol.3 Pemeliharaan tool

Vol.4 Forming tool

Vol.5 Material yang digunakan untuk memproduksi tool

Vol.6 Die Clearance

Vol.7 Mesin Turret Punch Press

Vol.8 Berbagai macam Bentuk spesial

Vol.9 Nama bagian-bagian tool standar

Vol.10 Forming tool

Vol.11 Jenis material (Baja)

Vol.12 Jenis material (Logam nonferrous)

Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

Vol.14 Tool bebas pengaturan ketinggian

Vol.15 Cara menggambar dan membaca gambar (Dasar)

Vol.16 Cara menggambar dan membaca gambar (Penggunaan praktis)

Vol.17 Instruksi bentuk untuk forming tools(1)

Vol.18 Instruksi bentuk untuk forming tools(2)

Vol.19 Manajemen kode

Vol.20 Informasi teknis bending

Vol.21 T&J konseling teknis(1) "COUNTERMEASURES FOR GALLING"

Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

Vol.23 T&J konseling teknis(3) "PITCH OF SINGLE PIERCING"

Vol.24 T&J konseling teknis(4) "SHEAR OPTIONS"

Vol.25 T&J konseling teknis(5) "HOLDING MARK"

Vol.26 T&J konseling teknis(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

Vol.27 T&J konseling teknis(7) "MATERIAL WARPING PREVENTION DURING"

Vol.28 T&J konseling teknis(8) "WARPING PREVENTION OF BLANKING OUT"

Vol.29 T&J konseling teknis(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

Vol.30 Panduan pemesanan(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

Vol.31 Panduan pemesanan(2) "REFERENCE KEY DIRECTION"

Vol.32 Panduan pemesanan(3) "ANGLE INDICATION OF ANGLED TOOL"

Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

Vol.34 Panduan pemesanan(5) "DIE SPECIFICATION SELECTION"