Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

This time, we will introduce “tap burring” and “weak spring type tools” from the questions that we have contacted the tool consultation.

BURRING FOR THREAD FORM

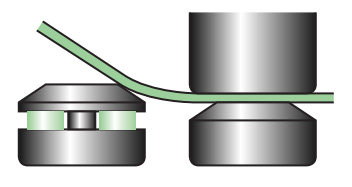

The burring end-face is slanted during tap burring.

(See Fig. 1) Is there a way to resolve it?

The biggest factor that the end-face of the tap burring is slanted is the positional deviation due to the positional accuracy of the forming tool and the pre-hole tooling by the turret T number.

As a countermeasure,

- 1.

Adjust the forming position of the pre-hole punching die and burring die on the program.

If there is a tendency to tilt the burring end-face, it may be resolved by slightly changing the forming position of the pre-hole punching die.

-

2.

The pre-hole and burring are process at the same time.

Our standard burring for thread forming tool is

- ・In case of downward forming, pre-hole one process type.

- ・In case of upward forming, the type that processes the pre-hole first.

However, we also have a “pre-hole one process type with upward forming”.

Fig. 1 Burring for thread form

ADVICE ON ONE POINT

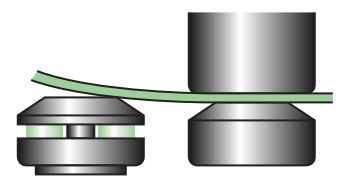

The die height of upward forming tools such as burring dies is higher than that of normal punching dies, and if the piercing is performed at a station near the forming tool, the workpiece may be damaged.

In such cases, a low height burring die is recommended.

(Applicable to t1.0 or less)

Fig.2 Comparison between standard burring die and low height burring die

ABOUT WEAK SPRING TYPE TOOL

When a sandwich steel plate is processed, a guide mark is attached to the plate and the product is not manufactured. Isn’t there anything you can do about it?

Normally, in piercing, the stronger the plate pressure, the better the shear results.

However, when processing a soft material such as a sandwich steel sheet,

the press marks on the guide or stripper may stick to the material.

As a countermeasure,

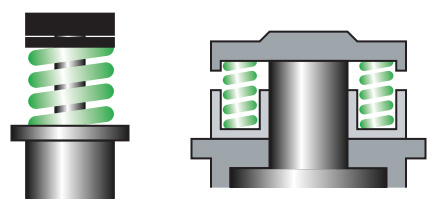

There is a method to weaken the punch spring.

We offer several types of springs.

By selecting an appropriate spring according to the material, it is possible to eliminate the holding mark.

If you can contact us, we will choose the best spring in our company.

Fig.3 Weak spring type tools

NOTICE

Using a weak spring for thick plate processing may cause a strip error.

Please use standard spring type tool for thick plate processing.

(To prevent stripping mistakes, a stripping force of 10% to 20% of the punching force is required.)

ADVICE ON ONE POINT

Other causes of guide marks include,

- ・The mounting defect of die. (Burr biting into the bottom of the die.)

- ・The defect parallelism of the guide and die end-faces.

(A failure in mounting a tool of setting during re-grinding) - ・A die (upward tooling die, etc.) with a height is mounted on a nearby station. are also considered.

Vol.1 Solusi untuk mencegah slug naik kepermukaan

Vol.2 Solusi untuk meningkatkan masa pakai tool

Vol.3 Pemeliharaan tool

Vol.4 Forming tool

Vol.5 Material yang digunakan untuk memproduksi tool

Vol.6 Die Clearance

Vol.7 Mesin Turret Punch Press

Vol.8 Berbagai macam Bentuk spesial

Vol.9 Nama bagian-bagian tool standar

Vol.10 Forming tool

Vol.11 Jenis material (Baja)

Vol.12 Jenis material (Logam nonferrous)

Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

Vol.14 Tool bebas pengaturan ketinggian

Vol.15 Cara menggambar dan membaca gambar (Dasar)

Vol.16 Cara menggambar dan membaca gambar (Penggunaan praktis)

Vol.17 Instruksi bentuk untuk forming tools(1)

Vol.18 Instruksi bentuk untuk forming tools(2)

Vol.19 Manajemen kode

Vol.20 Informasi teknis bending

Vol.21 T&J konseling teknis(1) "COUNTERMEASURES FOR GALLING"

Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

Vol.23 T&J konseling teknis(3) "PITCH OF SINGLE PIERCING"

Vol.24 T&J konseling teknis(4) "SHEAR OPTIONS"

Vol.25 T&J konseling teknis(5) "HOLDING MARK"

Vol.26 T&J konseling teknis(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

Vol.27 T&J konseling teknis(7) "MATERIAL WARPING PREVENTION DURING"

Vol.28 T&J konseling teknis(8) "WARPING PREVENTION OF BLANKING OUT"

Vol.29 T&J konseling teknis(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

Vol.30 Panduan pemesanan(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

Vol.31 Panduan pemesanan(2) "REFERENCE KEY DIRECTION"

Vol.32 Panduan pemesanan(3) "ANGLE INDICATION OF ANGLED TOOL"

Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

Vol.34 Panduan pemesanan(5) "DIE SPECIFICATION SELECTION"