Vol.2 Solusi untuk meningkatkan masa pakai tool

In punching process with a NC turret punch press, tool life has a major effect on productivity and cost.

This chapter has summarized some measures including Super Dry Punch, as measures for the tool life.

Super Dry Punch (SDP)

- ■Super Dry Punch (SDP) supports 【Dry Processing】 without using press processing oil.

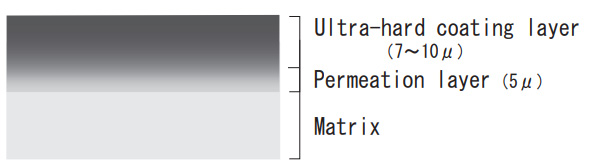

It exerts outstanding effects on difficult-to-process materials such as stainless steel. - ■Excellent durability is achieved by the double effect of the "super hard coating (Hv 2,500~3,000)" on the surface and the "penetration layer" to the punch base material.

Eliminated the "film peeling" defect that occurs when stainless steel is processed with conventional coating punches such as TiN (gold) and TiCN (gray purple).

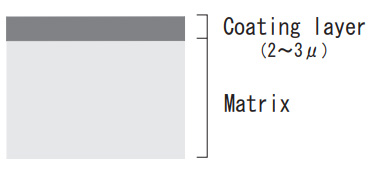

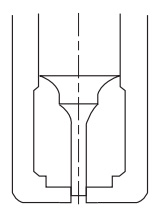

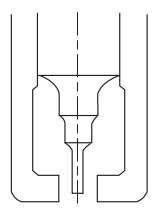

Conventional coating

Super Dry Punch (SDP)

- ■Durability test results of Super Dry Punch and TiCN coating

| Surface Treatment | TiCN Coating | Super Dry Punch (SDP) |

| Material & Thickness | SUS 304 t = 2.0 | SUS 304 t = 2.0 |

| Working Oil | Not in use (Non-oil Process) | Not in use (Non-oil Process) |

| The number of hits | About 20,000 hits | About 82,000 hits |

SURFACE TREATMENT VARIATION (APPROPRIATE)

| Total performance |

Punch type | Appropriate Material | Characteristics | |||

| Stainless steel | Mild steel | Aluminum | Galvanized | |||

| High Performance  Cost CostPerformance |

Super Dry Punch (SDP) |

★★★★★★ | ★★★★★★ | ★★★ | ★★★ | Highly effective in SUS material |

| Heavy Duty Punch (HDP) |

★★★★★ | ★★★★★★ | ★★★★★★ | ★★★★★★ | Excellent heat resistance | |

| Conic Long Life Punch (CLP) |

★★★★ | ★★★★★ | ★★★★★★ | ★★★★★★ | Emphasizing balance and Long life | |

| Conic Hard Punch (CHP) |

★★★ | ★★★★ | ★★★★★ | ★★★★ | High Cost Performance | |

| M2… No surface treatment |

★★ | ★★★ | ★★★ | ★★★ | ||

| D2… No surface treatment |

★ | ★ | ★★ | ★ | ||

SLITTING (NIBBLING) PROCESSING

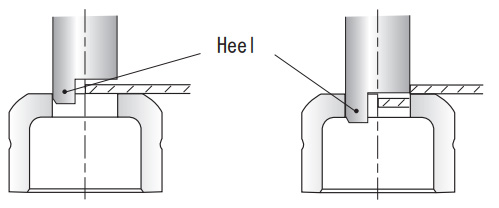

Heel tool

A tool that equipped with fixed heel part to punch and the heel part enters the die before the punch strikes the material,

prevents deviation of the punch during removal.

※ There is a limit on slitting direction.

Sharp Roof tool

In addition to this, there is also a sharp roof tool that has a movable heel part at the cutting edge to reduce restrictions on the slitting direction.

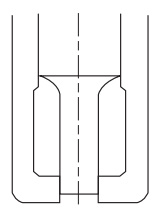

NARROW PUNCH

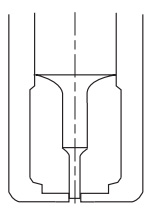

There is a punch type such as narrow type, open end type, super narrow type etc.

which made it difficult to break by shortening the effective punch length and increasing the strength of the punch.

〔 Standard type 〕

〔 Narrow type 〕

〔 Open-end type 〕

〔 Super-narrow type 〕

THICK PLATE PROCESSING

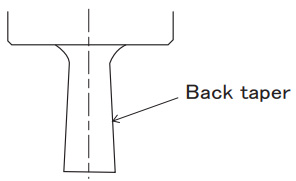

BACK TAPER

A tool that provide taper relief on the punch and reduce seizure and contact with the material.

OTHER LIFE COUNTERMEASURES

- 1.Check for misalignment of turret station and wear of turret key etc.

- 2.Combined use with tools for slug pulling measures.

- 3.Implementation of early regrinding.

- 4.Put a small rounding on the corner of Square / Rectangle punch.

As life countermeasures of the tool, it is recommended to select a tool that is acceptable for the processing conditions such as the quality and thickness of material.

Vol.1 Solusi untuk mencegah slug naik kepermukaan

Vol.2 Solusi untuk meningkatkan masa pakai tool

Vol.3 Pemeliharaan tool

Vol.4 Forming tool

Vol.5 Material yang digunakan untuk memproduksi tool

Vol.6 Die Clearance

Vol.7 Mesin Turret Punch Press

Vol.8 Berbagai macam Bentuk spesial

Vol.9 Nama bagian-bagian tool standar

Vol.10 Forming tool

Vol.11 Jenis material (Baja)

Vol.12 Jenis material (Logam nonferrous)

Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

Vol.14 Tool bebas pengaturan ketinggian

Vol.15 Cara menggambar dan membaca gambar (Dasar)

Vol.16 Cara menggambar dan membaca gambar (Penggunaan praktis)

Vol.17 Instruksi bentuk untuk forming tools(1)

Vol.18 Instruksi bentuk untuk forming tools(2)

Vol.19 Manajemen kode

Vol.20 Informasi teknis bending

Vol.21 T&J konseling teknis(1) "COUNTERMEASURES FOR GALLING"

Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

Vol.23 T&J konseling teknis(3) "PITCH OF SINGLE PIERCING"

Vol.24 T&J konseling teknis(4) "SHEAR OPTIONS"

Vol.25 T&J konseling teknis(5) "HOLDING MARK"

Vol.26 T&J konseling teknis(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

Vol.27 T&J konseling teknis(7) "MATERIAL WARPING PREVENTION DURING"

Vol.28 T&J konseling teknis(8) "WARPING PREVENTION OF BLANKING OUT"

Vol.29 T&J konseling teknis(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

Vol.30 Panduan pemesanan(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

Vol.31 Panduan pemesanan(2) "REFERENCE KEY DIRECTION"

Vol.32 Panduan pemesanan(3) "ANGLE INDICATION OF ANGLED TOOL"

Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

Vol.34 Panduan pemesanan(5) "DIE SPECIFICATION SELECTION"