Vol.4 Forming tool

Not only punching but also various forming processes are possible with the NC turret punch press.

TYPICAL FORMING PROCESS

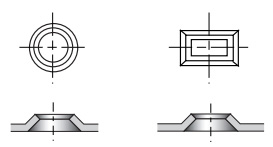

BURRING FOR THREAD FORM

Forming process for making tubes of threading for screw.

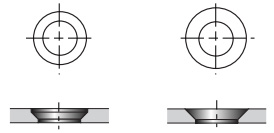

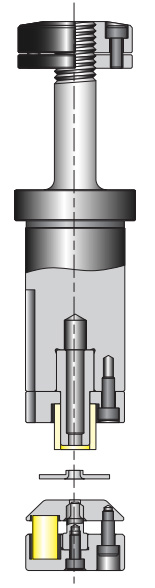

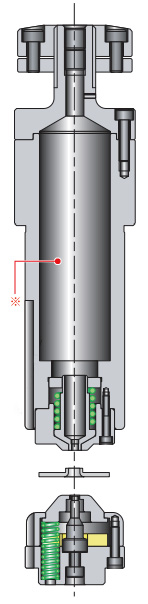

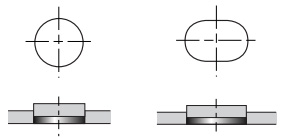

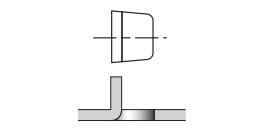

〔 Forming up 〕

〔 Forming down 〕

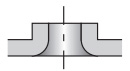

Pre-hole one process type

Die which performs pre-hole processing and burring at the same time.

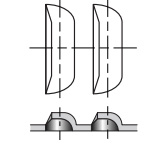

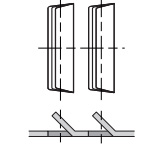

Pre-hole two process type

Die for burring after pre-hole processing

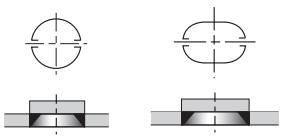

〔 FORMING DOWN 〕

(Pre-piercing and forming)

〔 FORMING UP 〕

(Forming after Pre-piercing)

〔 FORMING UP 〕

(Pre-piercing and forming)

※ Slug accumulates in the

upper tank.

Our standard dimension table

(other than upward & downward hole one process type)

| Screw size | Diameter of pin | Pre-hole |

| M2.5 | φ2.1 | φ1.2 |

| M3 | φ2.6 | φ1.5 |

| M4 | φ3.4 | φ2.0 |

| M5 | φ4.3 | φ2.4 |

| M6 | φ5.1 | φ2.8 |

- ※TiN coating is applied to the upward burring pin of standard dimension.

- ※In the case of non-standard dimensions, please indicate the pin diameter.

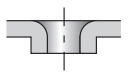

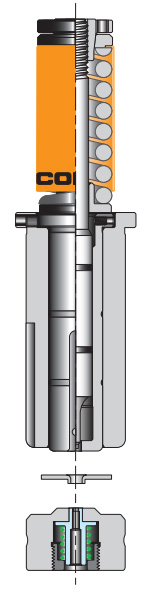

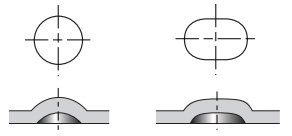

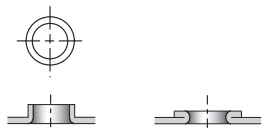

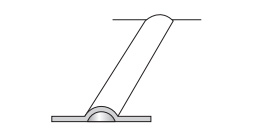

Center point

〔 Forming up 〕

〔 Forming down 〕

- ・The standard is a height adjustment free type.

(a die that required punch length adjustment for each plate thickness.) - ・Standard center punch angle is 90 degree.

Please specify if an angle other than 90 degree is desired. - ・The depth of the center point is optionally adjustable.

- ※We also produce a type that adjusts and fixes the punch length for each material thickness.

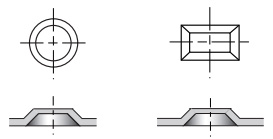

Examples of other major forming

| NAME | PRINCIPAL USE・SPECIAL NOTES |

COUNTERSINK FOR

|

|

HALF SHEAR

|

|

KNOCKOUT

|

|

EMBOSS (DIMPLE)

|

|

EMBOSS

|

|

COUNTERSINK

|

|

BURRING・CURLING

|

|

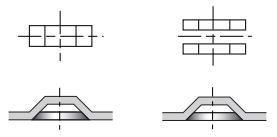

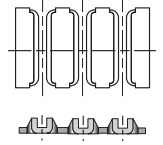

BRIDGE, DOUBLE BRIDGE

|

|

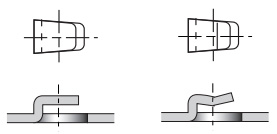

LANCE (Z-BENDING)

|

|

LANCE (L-BENDING)

|

|

BEADING

|

|

LOUVER FOR AIR FLOW

|

|

LANCE FOR AIR FLOW

|

|

CARD GUIDE

|

|

There are various other forming tools.

Please also see the information and images on our website.

PDF Download

Vol.1 Solusi untuk mencegah slug naik kepermukaan

Vol.2 Solusi untuk meningkatkan masa pakai tool

Vol.3 Pemeliharaan tool

Vol.4 Forming tool

Vol.5 Material yang digunakan untuk memproduksi tool

Vol.6 Die Clearance

Vol.7 Mesin Turret Punch Press

Vol.8 Berbagai macam Bentuk spesial

Vol.9 Nama bagian-bagian tool standar

Vol.10 Forming tool

Vol.11 Jenis material (Baja)

Vol.12 Jenis material (Logam nonferrous)

Vol.13 Rumus penghitungan yang populer digunakan dalam Lembaran logam

Vol.14 Tool bebas pengaturan ketinggian

Vol.15 Cara menggambar dan membaca gambar (Dasar)

Vol.16 Cara menggambar dan membaca gambar (Penggunaan praktis)

Vol.17 Instruksi bentuk untuk forming tools(1)

Vol.18 Instruksi bentuk untuk forming tools(2)

Vol.19 Manajemen kode

Vol.20 Informasi teknis bending

Vol.21 T&J konseling teknis(1) "COUNTERMEASURES FOR GALLING"

Vol.22 T&J konseling teknis(2) "BURRING FOR THREAD FORM"

Vol.23 T&J konseling teknis(3) "PITCH OF SINGLE PIERCING"

Vol.24 T&J konseling teknis(4) "SHEAR OPTIONS"

Vol.25 T&J konseling teknis(5) "HOLDING MARK"

Vol.26 T&J konseling teknis(6) "SOLUTION FOR SLUG PULLING OF A SHEET METAL WITH PROTECTIVE FILM"

Vol.27 T&J konseling teknis(7) "MATERIAL WARPING PREVENTION DURING"

Vol.28 T&J konseling teknis(8) "WARPING PREVENTION OF BLANKING OUT"

Vol.29 T&J konseling teknis(9) "COUNTERSINK FOR COUNTERSUNK SCREW"

Vol.30 Panduan pemesanan(1) "HOW TO INSTRUCT SHAPE AND DIMENSIONS"

Vol.31 Panduan pemesanan(2) "REFERENCE KEY DIRECTION"

Vol.32 Panduan pemesanan(3) "ANGLE INDICATION OF ANGLED TOOL"

Vol.33 Panduan pemesanan(4) "SELECT SPECIFICATION OF PUNCH"

Vol.34 Panduan pemesanan(5) "DIE SPECIFICATION SELECTION"