vol.9 PROBLEMS OF BENDING 2

(ANGLE DEFECT, MACHINE MAINTENANCE)

This time, let's think about angle defect.

ANGLE DEFECT

The angle defect is mainly affected by the machine and the material.

This time, let's divide the causes into “tool”, “machine”, and “material” and consider the countermeasures.

IF TOOL IS THE CAUSE

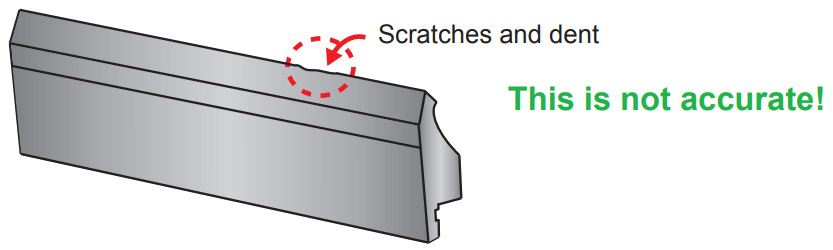

1. USE WORN AND DETERIORATED TOOLS

Perform regular re-sharpening of the cutting edge and inspection of the tool.

2. A TOOL THAT SHOULD NOT BE USED WAS USED

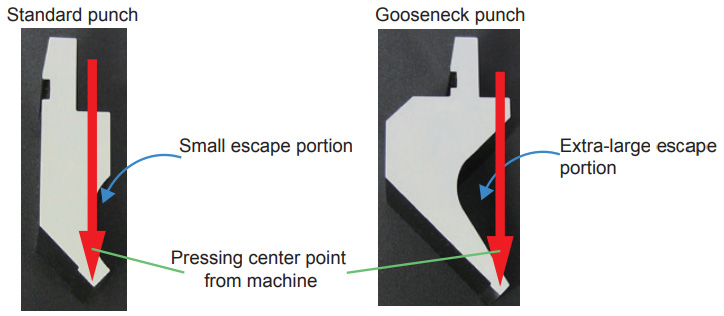

(e.g.) Gooseneck punch was used instead of standard punch.

Bending with a standard punch, compared to a gooseneck punch, has less deflection and better accuracy as the “C shape” of the tool relief is smaller.

Choosing the best tool for the bend is of the utmost importance.

IF THE MACHINE TABLE IS THE CAUSE

- ■Machine level is not right

- ■There is an error between the table rise and the punch lower position.

- ■There is a scratch on the tool mounting surface (the surface where pressure resistance is applied) on the machine side.

If you notice any of these incidents, contact the machine manufacturer for repair or maintenance.

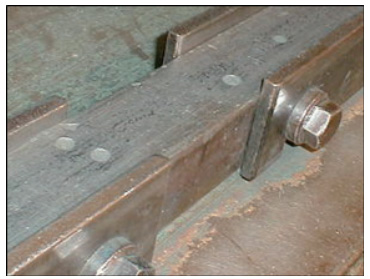

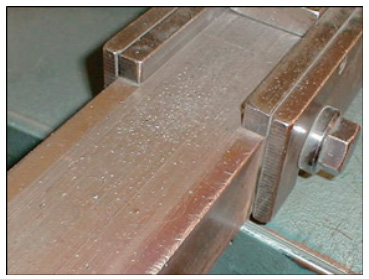

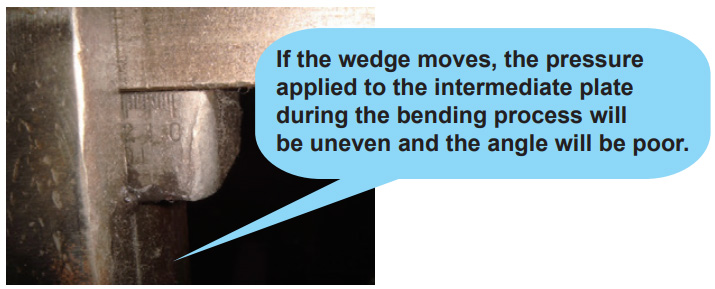

IN CASE OF INTERMADIATE PLATE

- 1.If it is deformed, scratched or damaged, repair or replace it.

Repair may be required if the pressing surface that the tool contacts is rough by touching it with your finger. - 2.If any bolts are loose or forgotten, tighten them.

- 3.If it is not mounted under pressure, it is mounted again.

Let's check periodically!

POINT

Machines that have been used for more than 20 years may have deteriorated in accuracy due to aging.

We recommend that you request an inspection from the machine manufacturer.

WHEN THE WORK MATERIAL IS THE CAUSE

- 1.Difference between nominal thickness and actual thickness.

- 2.Variation of sheet thickness for each lot.

- 3.Variations within a regular size sheet.

- 4.Differences in material properties between different manufacturers. (Hardness, etc.)

- 5.Materials with large errors that are seen in imported materials due to cost reductions.

When high-precision bending is required, the use of “high-precision material thickness” can reduce the variation compared to standard materials. Generally, the variation is about half of the standard material.

- ■Since the variation is extremely small, the total time of the bending operation is reduced.

- ■The accuracy is particularly stable with the obtuse bent product, and the defect rate is reduced.

These lead to improve sheet metal processing quality.

Although it has the disadvantage of increasing the cost of procurement,

it is also important to compareit with being busy with the work to deal with defects.

MACHINE MAINTENANCE

Many of the causes of failure involve machines. Here are some tips on the importance of daily maintenance.

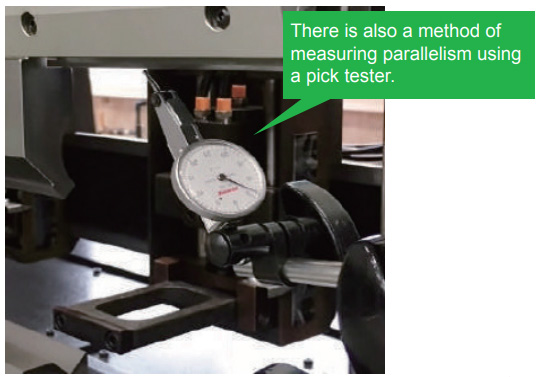

INSPECTION

Equipment maintenance is the most important part. There are “statutory inspection” and “voluntary inspection” in the inspection contents, and the purpose is to maintain the performance and accuracy of the machine. What is important is daily “self-checks”.

If you make the inspection cycle a routine, you will be able to find machine problems quickly.

REPAIR

This is also called “breakdown maintenance”, and it is to find out the cause of mechanical trouble and repair it. The types of failures are roughly divided into “breakdown” and “functional decline”.

If it can be repaired at the “functional decline” stage by voluntary inspection, it will be possible to repair at a relatively low cost without significantly affecting production.

MAINTENANCE

It is important to always maintain the product in a normal and usable condition.

Secure consumable replacement parts and replace them before they deteriorate.

-

vol.1 TYPE OF PRESS BRAKE TOOLS

-

vol.2 ABOUT V - BENDING TYPE

-

vol.3 PREPARATION FOR BENDING 1

(TONNAGE CHART , MINIMUM FLANGE LENGTH, V width selection) -

vol.4 PREPARATION FOR BENDING 2

(Punch marking example, V - BENDING FORCE CALCULATION FORMULA) -

vol.5 THE FEATURES OF BENDING

(BENDING ALLOWANCE, SPRING - BACK) -

vol.6 ABOUT TOOL SELECTION

(STEPS FOR CHOOSING A TOOL, STUDYING FROM THE DRAWINGS, READ DETAILS FROM DRAWINGS) -

vol.7 ABOUT TOOL INSTALLATION

(TOOL INSTALLATION PROCEDURE, ALIGNMENT PROCEDURE) -

vol.8 PROBLEMS OF BENDING

(DIMENSIONAL DEFECT AND ANGLE DEFECT, GUIDELINS FOR RE-POLISHING, COUNTERMEASURES OTHER THAN REGRINDING) -

vol.9 PROBLEMS OF BENDING 2

(ANGLE DEFECT, MACHINE MAINTENANCE) -

vol.10 PROBLEMS OF BENDING 3

(COUNTERMEASURE FOR CRACK / FRACTURE) -

vol.11 PROBLEMS OF BENDING 4

(SPRING-BACK MEASURES, WORK WARPAGE MEASURES, SHEARING METHOD AND WARPAGE TENDENCY BY SHEET METAL MACHINE) -

vol.12 TYPES OF BENDING SHAPES

(HEMMING BENDING, STEP BENDING) -

vol.13 BENDING FAQ 1

(TOOL INTERFERENCE, MINIMUM FLANGE LENGTH) -

vol.14 BENDING FAQ 2

(ABOUT TOOL SELECTION) -

vol.15 ABOUT TOOL MANAGEMENT

(EXAMPLE OF TOOL MANAGEMENT, EXTENDING TOOL LIFE) -

vol.16 PROBLEMS OF BENDING

-

vol.17 PROBLEMS OF BENDING

(BENDING BUMP MEASURES) -

vol.18 PROBLEMS OF BENDING