vol.2 ABOUT V - BENDING TYPE

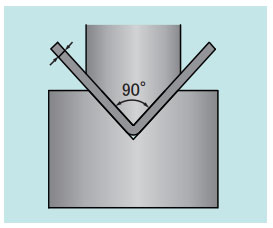

V-bending refers to bending at any angle based on 90° bending. Other examples include "R-bending",

which arbitrarily determines the radius of bending, and "Hemming bending", which bends and crushes the end of the product.

This time, let's look at the differences between the three basic types of V-bending.

![[ State of bending ]](../../images/tech/brake2_1.jpg)

At the manufacturing site, the definition of "bending angle" may be different.

Here, the inside angle of the bent product is referred to as the “bending angle”.

| V-Bending | TYPE | METHOD |

|---|---|---|

| AIR BENDING | PARTIAL BENDING | |

| BOTTOMING | ||

| COINING | ||

As for the V-bending method, understand the characteristics of the three types of bending on the next page and let them be able to perform appropriate bending.

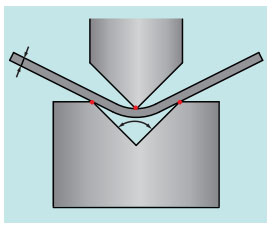

PARTIAL BENDING (AIR BENDING)

"Partial bending" means bending by pressing the tool and sheet material at three points as shown in the figure below.

Because the bending angle can be set freely from acute angle to obtuse angle, it is often used widely, such as the production of many kinds in small quantities and trial production, etc.

However, due to differences in materials and machine specifications, it is difficult to ensure stable angle accuracy,so advanced technology is required.

■ VARIATION OF BENDING ANGLE

±0.75°[ ±45′]

■ MERIT

Bending angle can be set freely.

■ DEMERIT

This is varying widely in angle compared to the bottoming.

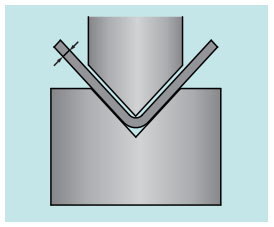

BOTTOMING (AIR BENDING)

High bending accuracy can be obtained with relatively small pressing force. However, since the amount of spring-back* is large,

it is common to bend extra. That is why there are variations such as the V-angle of 86°, 88°, 90°, etc. of the standard die with 90° bending.

As a general rule, use the same punch tip V angle and die V groove angle.

*"Spring-back" is a phenomenon in which the bent part of the material bounces slightly after bending.

■ VARIATION OF BENDING ANGLE

±0.5°[ ±30′]

■ MERIT

Accuracy can be obtained with less power than others.

■ DEMERIT

The amount of spring-back is large.

COINING

Coining means "coin" and comes from "creating coins". This is a bending method that provides extremely accurate bending accuracy and a small bending radius.

However, since the tip of the punch is encroached and bent into the material, the required tonnage is 5 to 8 times that of bottoming.

Care must be taken as the limit plate thickness depends on the difference in machine ability.

The pressure resistance of bending machine parts is usually guaranteed in tonnage per unit length.

If a SPCC 1.6mm is bent, it will be ≒75 tons per meter, and ≒115 tons with a thickness of 2mm, depending on the withstand pressure of each part, as a measure of the limit thickness is 2mm.

This is a bending method that has become rarely used due to the evolution of machines.

■ VARIATION OF BENDING ANGLE

±0.25°[ ±15′]

■ MERIT

The amount of spring-back is extremely small.

High accuracy can be obtained.

■ DEMERIT

Requires 5 to 8 times the pressurizing force of bottoming.

The required tonnage, V-width selection, ir (inner radius), and other basic settings will be introduced in Vol.3 and 4.

PDF Download

-

vol.1 TYPE OF PRESS BRAKE TOOLS

-

vol.2 ABOUT V - BENDING TYPE

-

vol.3 PREPARATION FOR BENDING 1

(TONNAGE CHART , MINIMUM FLANGE LENGTH, V width selection) -

vol.4 PREPARATION FOR BENDING 2

(Punch marking example, V - BENDING FORCE CALCULATION FORMULA) -

vol.5 THE FEATURES OF BENDING

(BENDING ALLOWANCE, SPRING - BACK) -

vol.6 ABOUT TOOL SELECTION

(STEPS FOR CHOOSING A TOOL, STUDYING FROM THE DRAWINGS, READ DETAILS FROM DRAWINGS) -

vol.7 ABOUT TOOL INSTALLATION

(TOOL INSTALLATION PROCEDURE, ALIGNMENT PROCEDURE) -

vol.8 PROBLEMS OF BENDING

(DIMENSIONAL DEFECT AND ANGLE DEFECT, GUIDELINS FOR RE-POLISHING, COUNTERMEASURES OTHER THAN REGRINDING) -

vol.9 PROBLEMS OF BENDING 2

(ANGLE DEFECT, MACHINE MAINTENANCE) -

vol.10 PROBLEMS OF BENDING 3

(COUNTERMEASURE FOR CRACK / FRACTURE) -

vol.11 PROBLEMS OF BENDING 4

(SPRING-BACK MEASURES, WORK WARPAGE MEASURES, SHEARING METHOD AND WARPAGE TENDENCY BY SHEET METAL MACHINE) -

vol.12 TYPES OF BENDING SHAPES

(HEMMING BENDING, STEP BENDING) -

vol.13 BENDING FAQ 1

(TOOL INTERFERENCE, MINIMUM FLANGE LENGTH) -

vol.14 BENDING FAQ 2

(ABOUT TOOL SELECTION) -

vol.15 ABOUT TOOL MANAGEMENT

(EXAMPLE OF TOOL MANAGEMENT, EXTENDING TOOL LIFE) -

vol.16 PROBLEMS OF BENDING

-

vol.17 PROBLEMS OF BENDING

(BENDING BUMP MEASURES) -

vol.18 PROBLEMS OF BENDING