vol.4 PREPARATION FOR BENDING 2

(Punch marking example, V - BENDING FORCE CALCULATION FORMULA)

The tool should be selected with emphasis on the material, plate thickness and length of the product, and taking into account the height of the tool, inner R size, interference, etc.

To do this, To do so, it is necessary to understand the processing capabilities, limits, etc.

displayed on the tool.

〔 Indication of press brake tool 〕

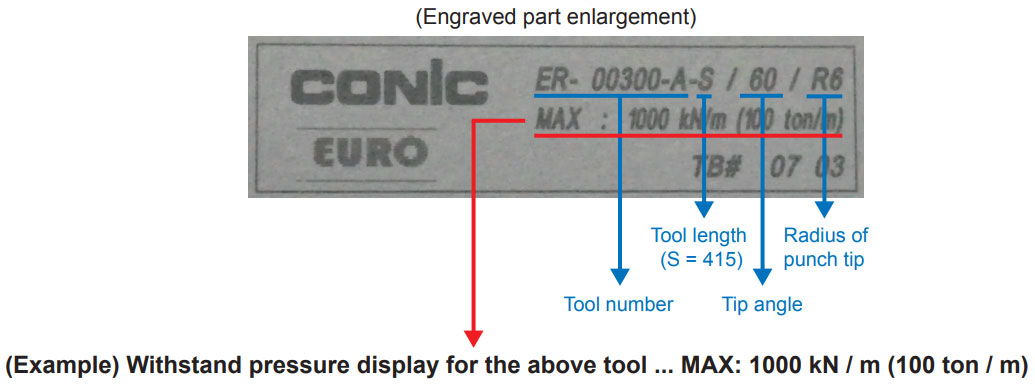

Basically, the following information is displayed on the tool.

Please note that the display method changes depending on each manufacturer.

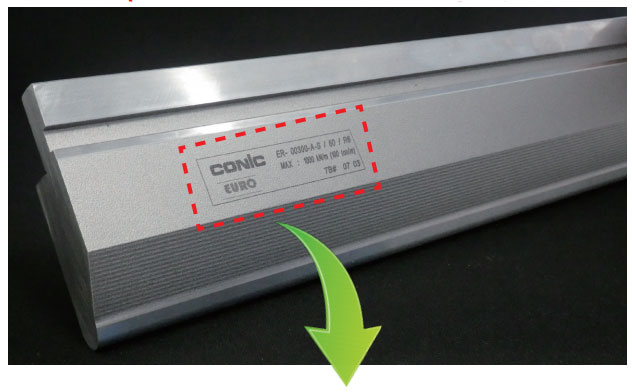

The tool picture below is an example of engraving displayed on the punch.

The die also displays other information such as V-width. Please be sure to check.

(Punch marking example)

*Since press brakes are processed on the bending line, they are indicated by linear pressure instead of surface pressure.

〔 About conversion of pressure resistance notation 〕

*m = Meter *kN = Kilonewton *ton = It means tons and indicates withstand pressure of "per meter".

If the above example is converted into each unit, it will be converted as 1kN ≒ 0.102ton, so it will be 1000kN ≒ 100 ton.

In other words, the force that this tool can apply per 1m is up to 1000kN or ≒ 100ton.

In addition, "feet" may be displayed depending on the tool.

〔 Required tonnage 〕

It is very important to know the required tonnage when bending with press brakes.

It is listed as a tonnage chart in catalogs, etc. Here, let's consider calculation formulas as basic knowledge.

The data in the tonnage chart are the values when the bottoming and the SPCC are bent using the following formula.

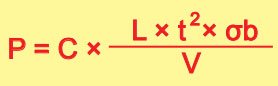

〔 V-BENDING FORCE CALCULATION FORMULA 〕

Mathematical Formula 1

- P:Tonnage required for V-bending (ton / m)

- C:Correction factor ≒ 1.5

(Reference value because it changes with V / t) - V:V-width

- L:Bending length

- T:Material thickness

- σb:Tensile strength (Kgf / mm2) ≒ 45

(When JIS standard“SS41”is used. It changes depending on the material.)

〔 Note 〕

The "correction coefficient" is mainly V x 8t = 1.33 to V x 4t = 1.57, but an error of about 15% occurs depending on other material.

In addition, the required tonnage per meter is also obtained by the simplified formula 2 below.

Mathematical Formula 2

As a formula derived from experimental values, the required tonnage per meter can also be calculated using the following formula.

P = 68 x Material thickness x Material thickness ÷ V-width (for SS material)

"68" in the above equation is "correction coefficient x tensile strength", which is a large value because the maximum coefficient is applied in consideration of safety.

If the material and thickness change, the values also change.

Currently, the tonnage chart is used as it is when processing cold-rolled steel sheet materials and other materials are determined based on the tonnage chart,

When calculating the material and plate thickness other than the tonnage chart,

consider the following four relationships.

- 1)Pressure is inversely proportional to V width.

- 2)Pressure is proportional to bending length.

- 3)The pressure is proportional to the square of the thickness.

- 4)Pressure is proportional to tensile strength.

Example: What is the pressure when STAINLESS T = 1.5mm, L = 2m, tensile strength = 60?

- 1.For the V-width selection, the thickness from 0.5 to 2.6 mm from the formula (refer to the V-width selection table on the second page of Vol. 3) can be calculated as 6 x t.

6 x 1.5 = 9, and 9mm width is not the standard V-width, so select 10mm width from the tonnage chart (select a large value). - 2.Since the plate thickness 1.5mm is not included in the tonnage chart, select the closest 1.6mm.

P = 17 ton from the tonnage chart. Based on this, calculate the required tonnage using the following formula.

Answer: 17 x (1.5 / 1.6) 2 x 60/45 x 2 ≒ 40ton (For SUS, round up fractions)

From this answer, we can understand that "pressure is proportional to the square of the plate thickness" and "pressure is proportional to tensile strength".

PDF Download

-

vol.1 TYPE OF PRESS BRAKE TOOLS

-

vol.2 ABOUT V - BENDING TYPE

-

vol.3 PREPARATION FOR BENDING 1

(TONNAGE CHART , MINIMUM FLANGE LENGTH, V width selection) -

vol.4 PREPARATION FOR BENDING 2

(Punch marking example, V - BENDING FORCE CALCULATION FORMULA) -

vol.5 THE FEATURES OF BENDING

(BENDING ALLOWANCE, SPRING - BACK) -

vol.6 ABOUT TOOL SELECTION

(STEPS FOR CHOOSING A TOOL, STUDYING FROM THE DRAWINGS, READ DETAILS FROM DRAWINGS) -

vol.7 ABOUT TOOL INSTALLATION

(TOOL INSTALLATION PROCEDURE, ALIGNMENT PROCEDURE) -

vol.8 PROBLEMS OF BENDING

(DIMENSIONAL DEFECT AND ANGLE DEFECT, GUIDELINS FOR RE-POLISHING, COUNTERMEASURES OTHER THAN REGRINDING) -

vol.9 PROBLEMS OF BENDING 2

(ANGLE DEFECT, MACHINE MAINTENANCE) -

vol.10 PROBLEMS OF BENDING 3

(COUNTERMEASURE FOR CRACK / FRACTURE) -

vol.11 PROBLEMS OF BENDING 4

(SPRING-BACK MEASURES, WORK WARPAGE MEASURES, SHEARING METHOD AND WARPAGE TENDENCY BY SHEET METAL MACHINE) -

vol.12 TYPES OF BENDING SHAPES

(HEMMING BENDING, STEP BENDING) -

vol.13 BENDING FAQ 1

(TOOL INTERFERENCE, MINIMUM FLANGE LENGTH) -

vol.14 BENDING FAQ 2

(ABOUT TOOL SELECTION) -

vol.15 ABOUT TOOL MANAGEMENT

(EXAMPLE OF TOOL MANAGEMENT, EXTENDING TOOL LIFE) -

vol.16 PROBLEMS OF BENDING

-

vol.17 PROBLEMS OF BENDING

(BENDING BUMP MEASURES) -

vol.18 PROBLEMS OF BENDING