vol.16 PROBLEMS OF BENDING

Scratches that occur during bending greatly affect the quality of the product. In particular, the materials,

such as stainless steel, aluminum, PVC steel sheets, and color steel sheets,

usually do not become products if they are damaged, so countermeasures against scratches are an important issue.

This time, we have summarized the types of scratches that occur during bending and their countermeasures.

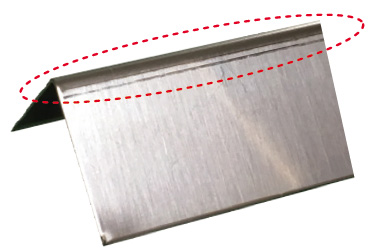

Example of bending scratch (sliding scratch)

There are three major types of bending scratches.

- 1.Sliding scratch: Scratches that occur most in V-bending. Scratches that occur when the work is rubbed on the shoulder of the die when the work is pushed into the die.

- 2.Joint scratch: Scratches caused by level difference or gaps at the joints when connecting the tools.

- 3.Ironing scratch: Scratches that occur when processing while ironing a workpiece with a punch.

(Occurs in hat-shape bending and U-bending)

This time, we will consider countermeasures for “1. Sliding scratches”, which are the most common during V-bending.

〔 Measures for slipping scratches 〕

- ■Increasing the die shoulder radius reduces scratches.

- ■Oil is applied to the shoulder of the die to reduce sliding resistance and reduce scratches.

- ■Applying a chrome plating treatment to the radius part of die shoulder, and improving the slip reduces scratches.

However, please note that the sheet itself may be broken and the material itself may be damaged depending on the V-width and the size of the shoulder radius.

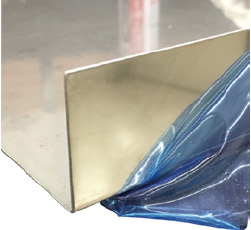

Example of bending with protective vinyl

If the above-mentioned “sliding scratch” countermeasures do not solve the problem, use a scratch prevention product for even higher effects.

On the next page, we will introduce products that specialize in scratch control.

SCRATCH PREVENTION PRODUCT

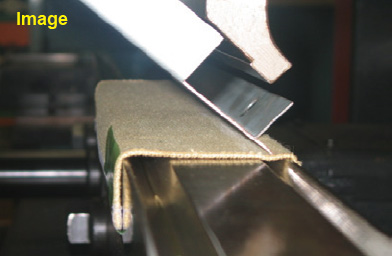

〔 Special sheet 〕

A sheet made of a special material that is used by attaching it to the top of the die to improve scratches.

Advantages of special seats,

Easy to prepare: Just place the sheet on the die and tape it, and preparation is quick.

Low-cost: Because it is more inexpensive than remodeling the tool or purchasing a dedicated tool, the cost can be kept low.

Scratch prevention effect: As long as the sheet does not deteriorate or break, it will continue to be highly effective in prevention.

Special sheet materials include synthetic fiber and resin.

Example of special sheet: Kizunon sheet

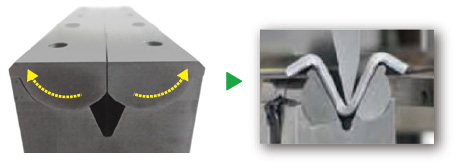

〔 Scratch-resistant tool 〕

The use of a special type prevents scratch by sliding.

As an example, there is a dedicated tool that prevents the shoulder from being damaged by opening and closing the die shoulder using the wing method.

For countermeasure tool example:

- ■Can be bend up to an acute angle of 40º

- ■Length variations are L=50, 100, 200, 500 (mm)

No scraches

Example of

bending SUS T = 1.5

Example of

bending bonderizing

sheet T = 1.0

Less hole deformation

even after bending after drilling

PDF Download

-

vol.1 TYPE OF PRESS BRAKE TOOLS

-

vol.2 ABOUT V - BENDING TYPE

-

vol.3 PREPARATION FOR BENDING 1

(TONNAGE CHART , MINIMUM FLANGE LENGTH, V width selection) -

vol.4 PREPARATION FOR BENDING 2

(Punch marking example, V - BENDING FORCE CALCULATION FORMULA) -

vol.5 THE FEATURES OF BENDING

(BENDING ALLOWANCE, SPRING - BACK) -

vol.6 ABOUT TOOL SELECTION

(STEPS FOR CHOOSING A TOOL, STUDYING FROM THE DRAWINGS, READ DETAILS FROM DRAWINGS) -

vol.7 ABOUT TOOL INSTALLATION

(TOOL INSTALLATION PROCEDURE, ALIGNMENT PROCEDURE) -

vol.8 PROBLEMS OF BENDING

(DIMENSIONAL DEFECT AND ANGLE DEFECT, GUIDELINS FOR RE-POLISHING, COUNTERMEASURES OTHER THAN REGRINDING) -

vol.9 PROBLEMS OF BENDING 2

(ANGLE DEFECT, MACHINE MAINTENANCE) -

vol.10 PROBLEMS OF BENDING 3

(COUNTERMEASURE FOR CRACK / FRACTURE) -

vol.11 PROBLEMS OF BENDING 4

(SPRING-BACK MEASURES, WORK WARPAGE MEASURES, SHEARING METHOD AND WARPAGE TENDENCY BY SHEET METAL MACHINE) -

vol.12 TYPES OF BENDING SHAPES

(HEMMING BENDING, STEP BENDING) -

vol.13 BENDING FAQ 1

(TOOL INTERFERENCE, MINIMUM FLANGE LENGTH) -

vol.14 BENDING FAQ 2

(ABOUT TOOL SELECTION) -

vol.15 ABOUT TOOL MANAGEMENT

(EXAMPLE OF TOOL MANAGEMENT, EXTENDING TOOL LIFE) -

vol.16 PROBLEMS OF BENDING

-

vol.17 PROBLEMS OF BENDING

(BENDING BUMP MEASURES) -

vol.18 PROBLEMS OF BENDING