vol.12 TYPES OF BENDING SHAPES (HEMMING BENDING, STEP BENDING)

There are many bending shapes and depending on the product dimensions and accuracy,

it cannot be bent at once, so multiple bending processes and multiple tools may be used. In recent years,

special tools have been developed and used to improve efficiency, safety and quality.

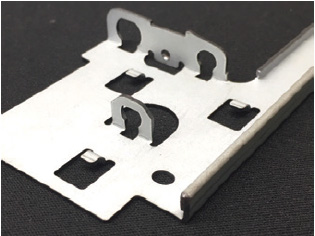

〔 Example of bending shape 〕

1. HEMMING BENDING

2. STEP BENDING

3. V-BENDING

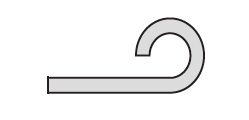

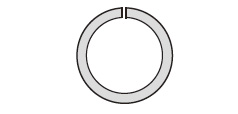

4. CURING

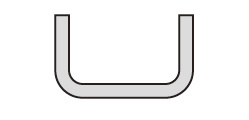

5. U-BENDING (1)

6. U-BENDING (2)

7. HAT SHAPE BENDING

8. PIPE BENDING

This time, 1. HEMMING BENDING and 2. STEP BENDING are taken up, and the dedicated tool is proposed below.

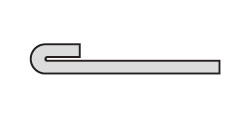

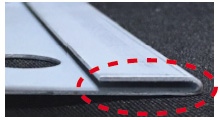

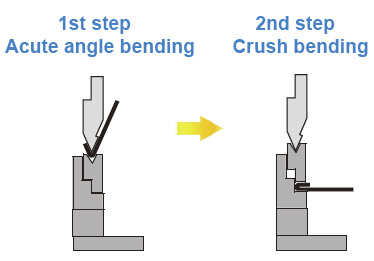

1. HEMMING BENDING

This is a method of bending and crushing the edge of a work, mainly for securing product strength and for safety measures.

When processing with a standard tool, not only the sheet metal quality may not be stable, such as a step at the bent part,

but also two types of tools for bending and crushing are required.

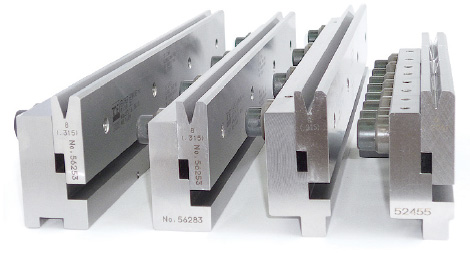

PREVENTIVE PRODUCT

FEATHER HEMMING

The “Feather Hemming (Die)” tool exclusively for hemming bending can be processed with one type of hemming in two steps.

It supports from corner hemming to split hemming, and can be easily adjusted even in environments where the tonnage of hydraulic machines is not stable.

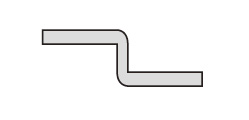

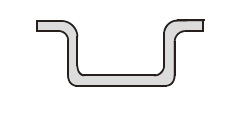

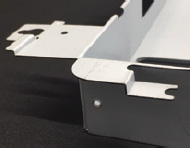

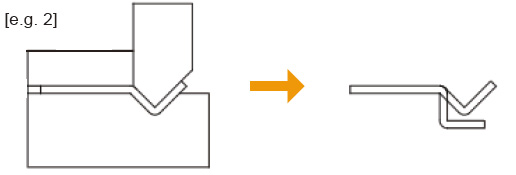

2. STEP BENDING

A method of processing a shape with steps, also called “Z-bending”.

For step bending, there is a method of performing V bending in two processes, but by using a dedicated tool, it can be processed in one process.

EXAMPLE OF 2-STEP BENDING

An example of two-step bending was given.

Using a standard tool has the advantage of being inexpensive,

but it tends to increase the number of processes and make the dimensions unstable. In addition,

experience is often required due to the difficulty in positioning the material.

PREVENTIVE PRODUCT

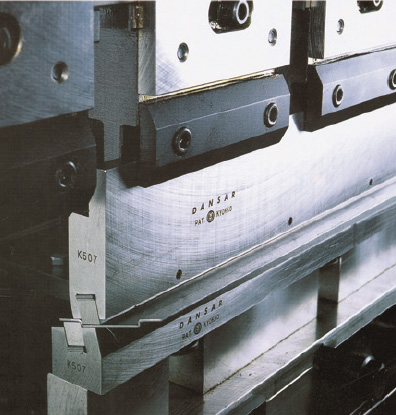

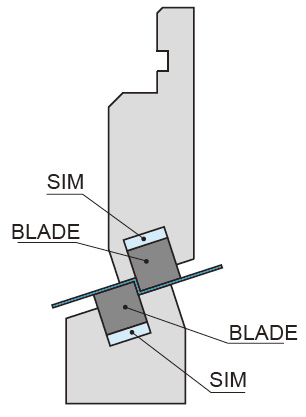

DANSAR

You can easily adjust the height of the steps simply by inserting a shim of the same thickness as the height of the steps.

Even when the tonnage of the hydraulic machine is not stable, adjustment is easy and dimensional accuracy is stable.

- *Please contact us in advance as some countries may not be available for sale.

-

vol.1 TYPE OF PRESS BRAKE TOOLS

-

vol.2 ABOUT V - BENDING TYPE

-

vol.3 PREPARATION FOR BENDING 1

(TONNAGE CHART , MINIMUM FLANGE LENGTH, V width selection) -

vol.4 PREPARATION FOR BENDING 2

(Punch marking example, V - BENDING FORCE CALCULATION FORMULA) -

vol.5 THE FEATURES OF BENDING

(BENDING ALLOWANCE, SPRING - BACK) -

vol.6 ABOUT TOOL SELECTION

(STEPS FOR CHOOSING A TOOL, STUDYING FROM THE DRAWINGS, READ DETAILS FROM DRAWINGS) -

vol.7 ABOUT TOOL INSTALLATION

(TOOL INSTALLATION PROCEDURE, ALIGNMENT PROCEDURE) -

vol.8 PROBLEMS OF BENDING

(DIMENSIONAL DEFECT AND ANGLE DEFECT, GUIDELINS FOR RE-POLISHING, COUNTERMEASURES OTHER THAN REGRINDING) -

vol.9 PROBLEMS OF BENDING 2

(ANGLE DEFECT, MACHINE MAINTENANCE) -

vol.10 PROBLEMS OF BENDING 3

(COUNTERMEASURE FOR CRACK / FRACTURE) -

vol.11 PROBLEMS OF BENDING 4

(SPRING-BACK MEASURES, WORK WARPAGE MEASURES, SHEARING METHOD AND WARPAGE TENDENCY BY SHEET METAL MACHINE) -

vol.12 TYPES OF BENDING SHAPES

(HEMMING BENDING, STEP BENDING) -

vol.13 BENDING FAQ 1

(TOOL INTERFERENCE, MINIMUM FLANGE LENGTH) -

vol.14 BENDING FAQ 2

(ABOUT TOOL SELECTION) -

vol.15 ABOUT TOOL MANAGEMENT

(EXAMPLE OF TOOL MANAGEMENT, EXTENDING TOOL LIFE) -

vol.16 PROBLEMS OF BENDING

-

vol.17 PROBLEMS OF BENDING

(BENDING BUMP MEASURES) -

vol.18 PROBLEMS OF BENDING