vol.5 THE FEATURES OF BENDING

(BENDING ALLOWANCE, SPRING - BACK)

BENDING ALLOWANCE

This time, let's think about the bending allowance. Bending allowance refers to the phenomenon of "shrinking" and "stretching" that occurs on the front and back of a material when performing bending work.

In general, turn the completed drawing into the plan view before performing sheet metal work.

This is called a “development drawing”.

In bending, it is important to take into account the “elongation allowance”and bend as shown in the plan view.

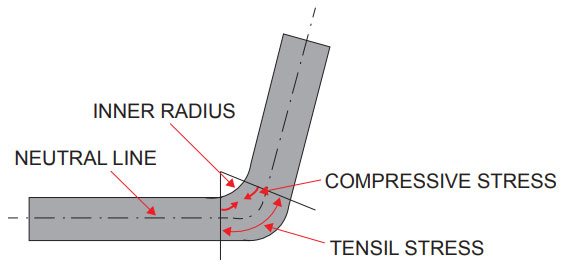

BENDING CROSS SECTION

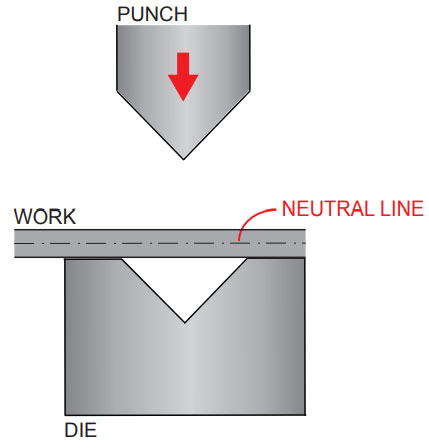

〔 Relation between neutral line and bending 〕

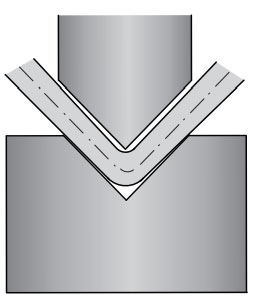

- ■As shown in the above figure, when the bending work is performed,

the phenomenon that the inside shrinks and the outside expands occurs. - ■Expansion and contraction occur inside and outside the neutral line.

- ■When converted to a plan view, this neutral line is the “development length”.

- ■The neutral line moves to the inside or outside of the plate depending on the processing conditions.

- ■In order to obtain a fine development length (bending allowance),

this neutral line greatly affects the bending quality.

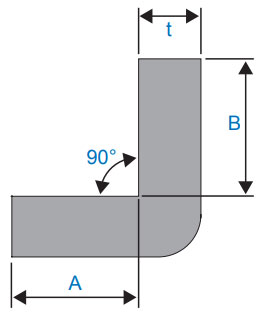

SIMPLE CALCULATION OF RIGHT ANGLE BENDING

L (deployment length) = A + B + 1 / 2 t

L (deployment length) = A + B + 1 / 2 t

- ■In actual work, this calculation is often used, but it is eventually corrected with experience.

Please consider it as a reference value. - ■The deployment dimensions of bending vary depending not only on the tool structure but also on the material and thickness.

A spring-back, which will be described later, also has a large effect, and it is extremely difficult to obtain an accurate deployment length.

Therefore, engineers with more experience value are more useful today as the number of complicated bending and bending times increases.

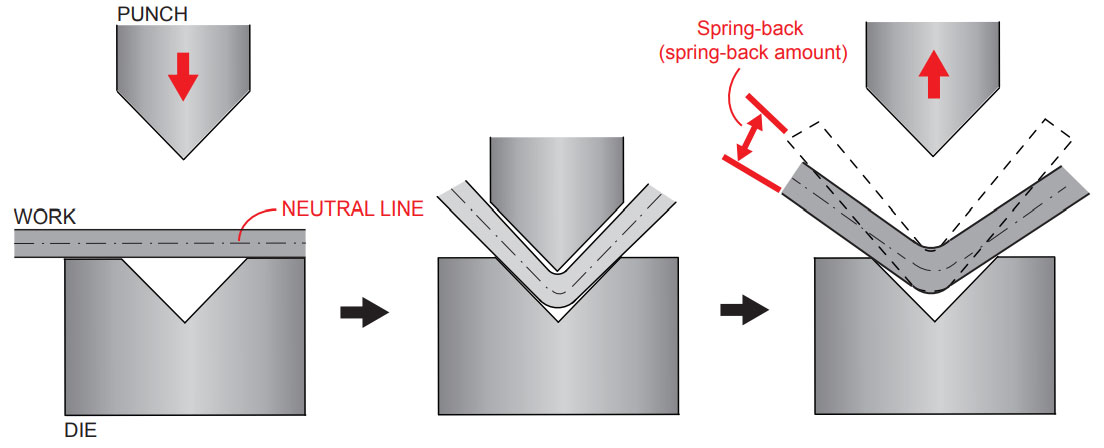

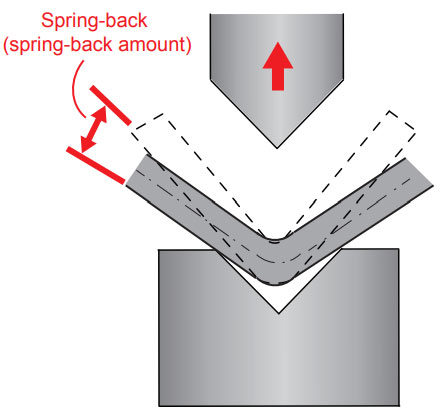

SPRING-BACK

Spring-back is a phenomenon in which the bending angle rebounds when pressure is removed after bending.

When the work is bent, opposing stresses such as "shrinking" and "pulling" are applied between the inside and the outside.

Generally, the compressive strength is much greater than the tensile strength.

Therefore, even when the outside of the work reaches the bending angle and the angular deformation is completed to some extent; a force toward the outside is still working inside to return to the original state.

This compressive stress is spring-back.

The spring-back amount is generally represented by an angle, but it is difficult to accurately predict it because it changes depending on various conditions such as the material and the thickness of the plate.

Also, depending on the state of the pressure during bending, when the repulsive force changes and the pressure is removed, the angle may enter and the state may be opposite to the spring-back.

This is called Spring-go.

〔 SPRING-BACK MECHANISM 〕

〔 Spring-back phenomenon trends 〕

- 1.With the same tool and same thickness ... COLD MILD STEEL < ALMINUM < STAINLESS

- 2.In the same tool, the smaller the material thickness, the greater the spring-back amount.

- 3.The amount varies depending on the finishing angle.

- 4.The larger the “bending R” with respect to the material thickness, the larger the spring-back amount.

- ■Spring-back is a phenomenon that always occurs in bending work.

ONE POINT

Many people wonder if the amount of spring-back can be calculated by calculation.

There is a calculation formula, but it is complicated, and it is basically used when manufacturing tools for press working, and cannot be used for bending.

The main reason is

- 1.The fact that the press brake tool has a cutting edge angle of 88° etc. itself is made in consideration of the amount of spring-back, indicating that the product bending is not bent to 90° as calculated.

In addition, it is difficult to calculate the error. - 2.It is easier to adjust the inner radius than to calculate the spring-back amount.

- 3.An angle check is required because errors in calculated values increase due to variations in material thickness and differences in mechanical specifications.

-

vol.1 TYPE OF PRESS BRAKE TOOLS

-

vol.2 ABOUT V - BENDING TYPE

-

vol.3 PREPARATION FOR BENDING 1

(TONNAGE CHART , MINIMUM FLANGE LENGTH, V width selection) -

vol.4 PREPARATION FOR BENDING 2

(Punch marking example, V - BENDING FORCE CALCULATION FORMULA) -

vol.5 THE FEATURES OF BENDING

(BENDING ALLOWANCE, SPRING - BACK) -

vol.6 ABOUT TOOL SELECTION

(STEPS FOR CHOOSING A TOOL, STUDYING FROM THE DRAWINGS, READ DETAILS FROM DRAWINGS) -

vol.7 ABOUT TOOL INSTALLATION

(TOOL INSTALLATION PROCEDURE, ALIGNMENT PROCEDURE) -

vol.8 PROBLEMS OF BENDING

(DIMENSIONAL DEFECT AND ANGLE DEFECT, GUIDELINS FOR RE-POLISHING, COUNTERMEASURES OTHER THAN REGRINDING) -

vol.9 PROBLEMS OF BENDING 2

(ANGLE DEFECT, MACHINE MAINTENANCE) -

vol.10 PROBLEMS OF BENDING 3

(COUNTERMEASURE FOR CRACK / FRACTURE) -

vol.11 PROBLEMS OF BENDING 4

(SPRING-BACK MEASURES, WORK WARPAGE MEASURES, SHEARING METHOD AND WARPAGE TENDENCY BY SHEET METAL MACHINE) -

vol.12 TYPES OF BENDING SHAPES

(HEMMING BENDING, STEP BENDING) -

vol.13 BENDING FAQ 1

(TOOL INTERFERENCE, MINIMUM FLANGE LENGTH) -

vol.14 BENDING FAQ 2

(ABOUT TOOL SELECTION) -

vol.15 ABOUT TOOL MANAGEMENT

(EXAMPLE OF TOOL MANAGEMENT, EXTENDING TOOL LIFE) -

vol.16 PROBLEMS OF BENDING

-

vol.17 PROBLEMS OF BENDING

(BENDING BUMP MEASURES) -

vol.18 PROBLEMS OF BENDING