vol.6 ABOUT TOOL SELECTION

(STEPS FOR CHOOSING A TOOL, STUDYING FROM THE DRAWINGS, READ DETAILS FROM DRAWINGS)

Until Vol.5, preparation for tool selection has been described, but from this time on,

it will be into a practical tool selection method. This page features "V-bending" and "R-bending".

These bending methods are considered "standard machining procedures" and account for the majority of standard tools in the catalog.

STEPS FOR CHOOSING A TOOL

When choosing the tool, it is necessary to check the completed and development drawings and make a comprehensive determination.

To do so, it is important to check that all necessary conditions are met and to select the appropriate tool.

When the phenomenon such as "Bending is insufficient and angle does not come out" or "Poor accuracy" appears, it is common when the following contents are omitted.

〔 Check the following items to make a comprehensive decision. 〕

- 1.Machine specifications

- 2.Determine V width

- 3.Tool combination

- 4.Bending sequence

- 5.Required pressure (withstand pressure)

STUDYING FROM THE DRAWINGS

Study the contents of the table below from the drawing and select the tool.

| Confirmation items | Confirmation contents |

| Material (SPCC / SUS / AL) | Allowable tonnage, tool tip angle (against spring-back) |

| Material Thickness | Selection of V groove width, tool pressure resistance tonnage for required bending tonnage |

| Bending length | Allowable tonnage, Length and depth of machine table length side plate |

| Inner radius | Coining (inner R0.8t~) Air bending (General bending)(inner R1t~2.8t) R-bending (inner R2.8t or more) |

READ DETAILS FROM DRAWINGS

Basic tools can be selected from the contents on the previous page,

but there are cases where it is necessary to select tools that require simulation, such as "complex bending" and "multi-point bending."

Please see below.

Together with the items on the previous page

- 6.Select the machine to use

- 7.Tool specification

- 8.Determine working conditions

| Confirmation items | Confirmation contents |

| Bending length / height | Minimum length = V-width x 0.7 Table length, Flange length / side plate distance |

| Z bending dimension | V-groove depth 1st process, Bending height (Material thickness step), |

| Total width of inverse bending | Die length |

| Box bending | Punch length |

| Tooling points such as burring | Tool interference |

| Box bending / Width dimension | Sectional tool length |

| Hole position near the bending part | Beware of deformation |

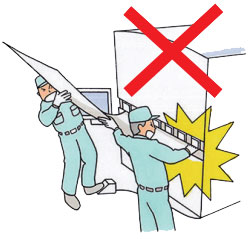

| Width dimension / Weight | Number of people performing bending, Storage of product |

| Accuracy | Check bending order |

|

Surface condition (Surface without scratch) |

Scratch prevention measures (Die shoulder R, Plating, etc.) |

When choosing a tool, double check that you have a die!

Surprisingly, they often see the punch and forget the die.

The die has a large effect on the processed material, such as scratches and deflection on the product,

so check it carefully.

Check the dies before starting work,

and safely perform high-quality bending.

-

vol.1 TYPE OF PRESS BRAKE TOOLS

-

vol.2 ABOUT V - BENDING TYPE

-

vol.3 PREPARATION FOR BENDING 1

(TONNAGE CHART , MINIMUM FLANGE LENGTH, V width selection) -

vol.4 PREPARATION FOR BENDING 2

(Punch marking example, V - BENDING FORCE CALCULATION FORMULA) -

vol.5 THE FEATURES OF BENDING

(BENDING ALLOWANCE, SPRING - BACK) -

vol.6 ABOUT TOOL SELECTION

(STEPS FOR CHOOSING A TOOL, STUDYING FROM THE DRAWINGS, READ DETAILS FROM DRAWINGS) -

vol.7 ABOUT TOOL INSTALLATION

(TOOL INSTALLATION PROCEDURE, ALIGNMENT PROCEDURE) -

vol.8 PROBLEMS OF BENDING

(DIMENSIONAL DEFECT AND ANGLE DEFECT, GUIDELINS FOR RE-POLISHING, COUNTERMEASURES OTHER THAN REGRINDING) -

vol.9 PROBLEMS OF BENDING 2

(ANGLE DEFECT, MACHINE MAINTENANCE) -

vol.10 PROBLEMS OF BENDING 3

(COUNTERMEASURE FOR CRACK / FRACTURE) -

vol.11 PROBLEMS OF BENDING 4

(SPRING-BACK MEASURES, WORK WARPAGE MEASURES, SHEARING METHOD AND WARPAGE TENDENCY BY SHEET METAL MACHINE) -

vol.12 TYPES OF BENDING SHAPES

(HEMMING BENDING, STEP BENDING) -

vol.13 BENDING FAQ 1

(TOOL INTERFERENCE, MINIMUM FLANGE LENGTH) -

vol.14 BENDING FAQ 2

(ABOUT TOOL SELECTION) -

vol.15 ABOUT TOOL MANAGEMENT

(EXAMPLE OF TOOL MANAGEMENT, EXTENDING TOOL LIFE) -

vol.16 PROBLEMS OF BENDING

-

vol.17 PROBLEMS OF BENDING

(BENDING BUMP MEASURES) -

vol.18 PROBLEMS OF BENDING