vol.17 PROBLEMS OF BENDING

(BENDING BUMP MEASURES)

One of the most common problems in bending is “bending bumps”.

This time, we will explain examples of defects caused by “bending bumps” and countermeasures.

BENDING BUMP

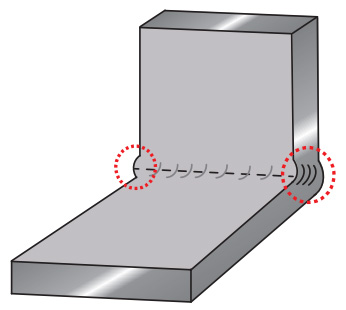

“Bending bump” is a phenomenon in which the end faces of the plate bulge when bending, and it protrudes like a bump.

The size of the “bending bump” varies depending on the plate thickness.

If you proceed to the next process with the “bending bump”, it may cause troubles. It is necessary to be careful in processing work, not as a measure with a tool.

〔 TYPICAL BENDING BUMP EXAMPLES 〕

Bulge amount of bending bumps guideline

In the case of Bottoming … t × 0.15

In the case of Coining … t × 0.12

A FAILURE CAUSED BY BENDING BUMP

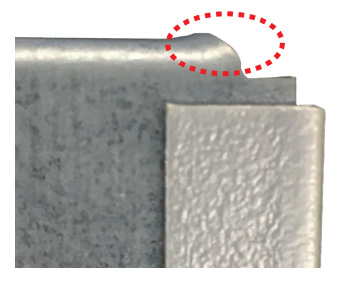

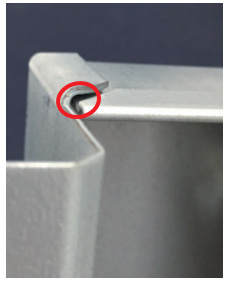

〔 Bending Interference 1 〕

When box bending is performed with the “bending bumps” remaining, the bumps interfere with each other to open a gap, greatly affecting the bending angle and accuracy.

Furthermore, the welding work in the post process becomes difficult, which leads to defective processing.

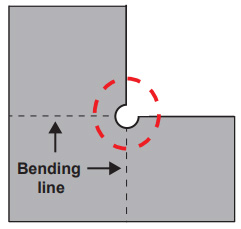

As a method for suppressing the bending bump, it may be possible to improve it by making a hole with diameter larger than the plate thickness.

(Measures plan)

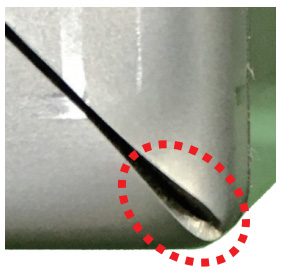

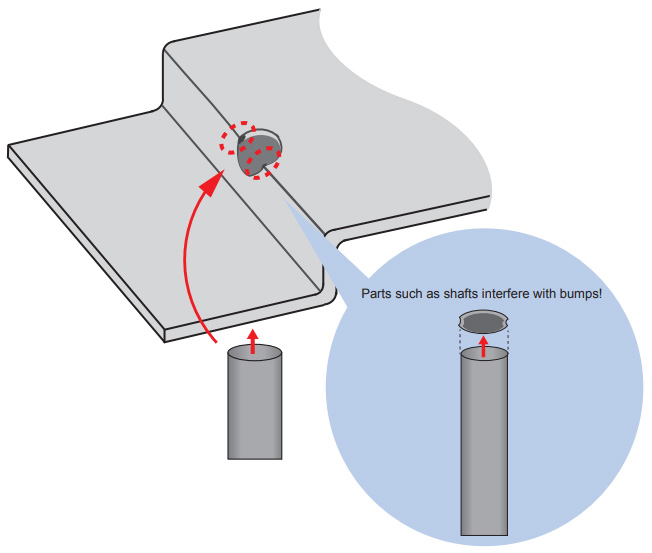

〔 Bending Interference 2 〕

If there is a hole on the bending line to mount a precision part such as a shaft, the bending bump may interfere.

Parts such as shafts interfere with bumps!

Parts such as shafts interfere with bumps!

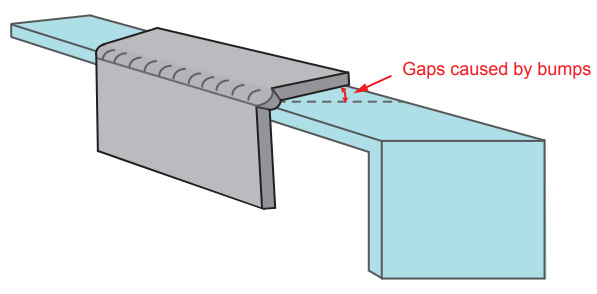

〔 Bending Interference 3 〕

Even when the bending parts are combined, there may be gaps due to the bending bumps, resulting in rattling.

Be careful when setting tolerances.

BENDING BUMP MEASURES

〔 SOLUTION 〕

- 1.If T=1.6 or more, remove the bumps after processing.

- 2.Provide a relief part when unfolding.

- 3.Use a tool with a large tip R.

It is important to consider bending bump measures at the stage of producing a prototype.

If it takes a lot of man-power to remove it, it will affect the delivery time, and if you change the bending radius,

it will lead to cost increase due to changes in tool purchase costs and setup, so be sure to take measures beforehand.

-

vol.1 TYPE OF PRESS BRAKE TOOLS

-

vol.2 ABOUT V - BENDING TYPE

-

vol.3 PREPARATION FOR BENDING 1

(TONNAGE CHART , MINIMUM FLANGE LENGTH, V width selection) -

vol.4 PREPARATION FOR BENDING 2

(Punch marking example, V - BENDING FORCE CALCULATION FORMULA) -

vol.5 THE FEATURES OF BENDING

(BENDING ALLOWANCE, SPRING - BACK) -

vol.6 ABOUT TOOL SELECTION

(STEPS FOR CHOOSING A TOOL, STUDYING FROM THE DRAWINGS, READ DETAILS FROM DRAWINGS) -

vol.7 ABOUT TOOL INSTALLATION

(TOOL INSTALLATION PROCEDURE, ALIGNMENT PROCEDURE) -

vol.8 PROBLEMS OF BENDING

(DIMENSIONAL DEFECT AND ANGLE DEFECT, GUIDELINS FOR RE-POLISHING, COUNTERMEASURES OTHER THAN REGRINDING) -

vol.9 PROBLEMS OF BENDING 2

(ANGLE DEFECT, MACHINE MAINTENANCE) -

vol.10 PROBLEMS OF BENDING 3

(COUNTERMEASURE FOR CRACK / FRACTURE) -

vol.11 PROBLEMS OF BENDING 4

(SPRING-BACK MEASURES, WORK WARPAGE MEASURES, SHEARING METHOD AND WARPAGE TENDENCY BY SHEET METAL MACHINE) -

vol.12 TYPES OF BENDING SHAPES

(HEMMING BENDING, STEP BENDING) -

vol.13 BENDING FAQ 1

(TOOL INTERFERENCE, MINIMUM FLANGE LENGTH) -

vol.14 BENDING FAQ 2

(ABOUT TOOL SELECTION) -

vol.15 ABOUT TOOL MANAGEMENT

(EXAMPLE OF TOOL MANAGEMENT, EXTENDING TOOL LIFE) -

vol.16 PROBLEMS OF BENDING

-

vol.17 PROBLEMS OF BENDING

(BENDING BUMP MEASURES) -

vol.18 PROBLEMS OF BENDING