vol.10 PROBLEMS OF BENDING 3

(COUNTERMEASURE FOR CRACK / FRACTURE)

This time, we will explain the main causes of cracks and countermeasures.

COUNTERMEASURE FOR CRACK / FRACTURE

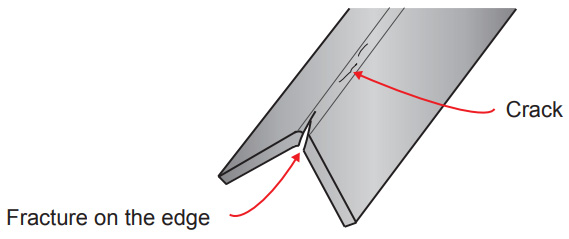

A crack is a “fracture” and is a common phenomenon in bent parts.

As it progresses, it may become a “rip”.

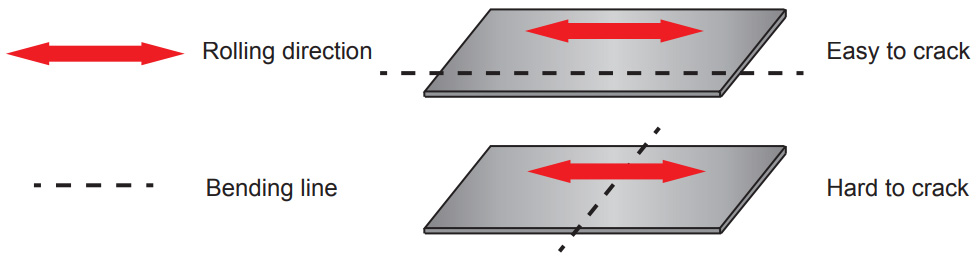

〔 Relationship with material rolling direction 〕

FACTOR

Cracks are likely to occur when bent in parallel to the rolling direction of the material.

If the material is bent parallel to the rolling direction, cracks are likely to occur.

MEASURES

Increase inner radius. Especially for aluminum materials, it is desirable that the R is more than the plate thickness.

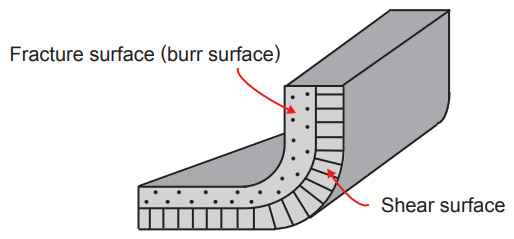

〔 Relationship with burr direction 〕

FACTOR

When bending a material punched with a tool, the rate of occurrence of cracks varies between the inside and outside burr directions.

MEASURES

- 1.The better the surface roughness of the material, the greater the elongation limit = the less

likely it is to crack. The material extracted in the tool has a fracture surface on the burr direction side.

Therefore, cracks are less likely to occur when a shear surface is brought to the outside. - 2.If the outer R side is a fracture surface (burr surface) and the inner R side is a shear surface,

deburr in advance and adjust the surface roughness before bending.

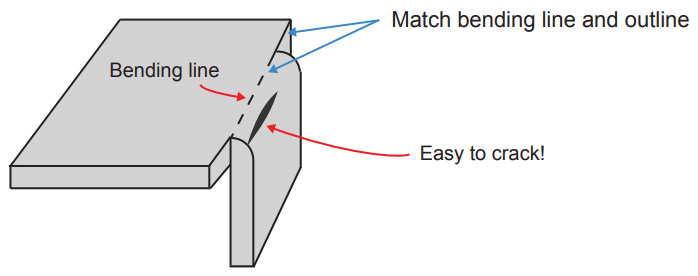

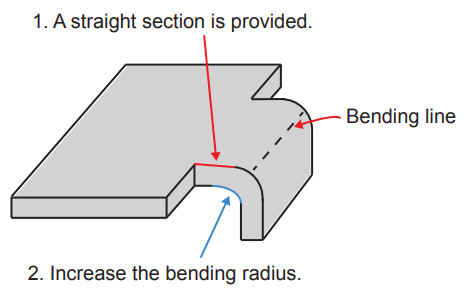

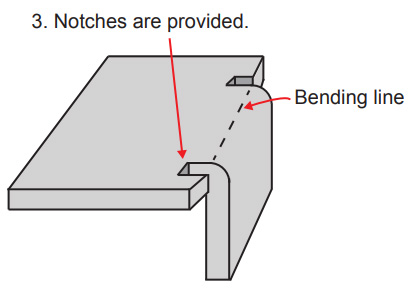

〔 Relationship between external shape and bending line 〕

FACTOR

As shown in the illustration below, if the outline of the blank and the bending line match,

the outline of the blank in the bending radius area is disturbed, so that the material cannot be moved due to bending and does not stretch.

MEASURES

- 1.Displace the bending line and the outline, and attach a straight part.

- 2.Increase the bending radius.

- 3.If 1 and 2 are not possible, make a cut. (Reference: Material thickness ~ About twice of material thickness)

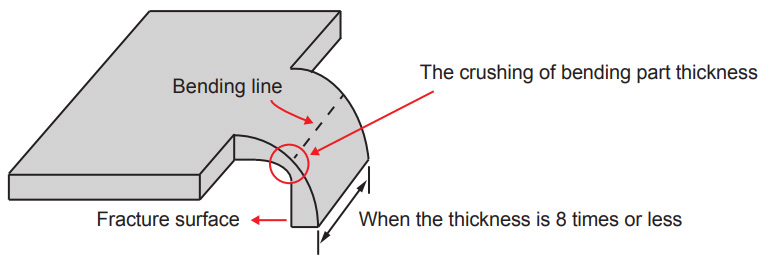

〔 Relationship with bending width 〕

FACTOR

In the case of a narrow bend having a bending width of eight times or less the plate thickness,

the bend is in a crushed state, which also affects the bending width direction, and the bend is easily broken.

MEASURES

- 1.Reduce the bending speed.

- 2.Increase the bending radius.

- 3.Set the burr direction (fracture surface) inside the bend.

-

vol.1 TYPE OF PRESS BRAKE TOOLS

-

vol.2 ABOUT V - BENDING TYPE

-

vol.3 PREPARATION FOR BENDING 1

(TONNAGE CHART , MINIMUM FLANGE LENGTH, V width selection) -

vol.4 PREPARATION FOR BENDING 2

(Punch marking example, V - BENDING FORCE CALCULATION FORMULA) -

vol.5 THE FEATURES OF BENDING

(BENDING ALLOWANCE, SPRING - BACK) -

vol.6 ABOUT TOOL SELECTION

(STEPS FOR CHOOSING A TOOL, STUDYING FROM THE DRAWINGS, READ DETAILS FROM DRAWINGS) -

vol.7 ABOUT TOOL INSTALLATION

(TOOL INSTALLATION PROCEDURE, ALIGNMENT PROCEDURE) -

vol.8 PROBLEMS OF BENDING

(DIMENSIONAL DEFECT AND ANGLE DEFECT, GUIDELINS FOR RE-POLISHING, COUNTERMEASURES OTHER THAN REGRINDING) -

vol.9 PROBLEMS OF BENDING 2

(ANGLE DEFECT, MACHINE MAINTENANCE) -

vol.10 PROBLEMS OF BENDING 3

(COUNTERMEASURE FOR CRACK / FRACTURE) -

vol.11 PROBLEMS OF BENDING 4

(SPRING-BACK MEASURES, WORK WARPAGE MEASURES, SHEARING METHOD AND WARPAGE TENDENCY BY SHEET METAL MACHINE) -

vol.12 TYPES OF BENDING SHAPES

(HEMMING BENDING, STEP BENDING) -

vol.13 BENDING FAQ 1

(TOOL INTERFERENCE, MINIMUM FLANGE LENGTH) -

vol.14 BENDING FAQ 2

(ABOUT TOOL SELECTION) -

vol.15 ABOUT TOOL MANAGEMENT

(EXAMPLE OF TOOL MANAGEMENT, EXTENDING TOOL LIFE) -

vol.16 PROBLEMS OF BENDING

-

vol.17 PROBLEMS OF BENDING

(BENDING BUMP MEASURES) -

vol.18 PROBLEMS OF BENDING