3) COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

OUTLINE OF FORMING

Forming process of making a chamfer to material.

Used for sink a countersunk screw head, make chamfer to a corner after punching, guide of tapping.

NOTE

-

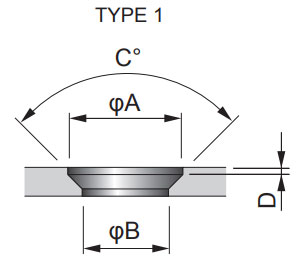

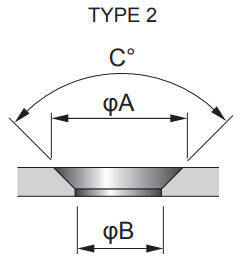

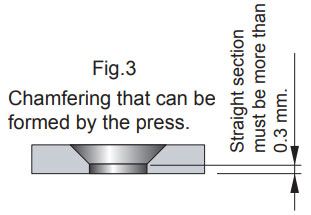

1) The shape of the chamfer.

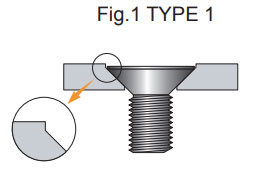

(TYPE 1) Chamfer with a straight section. (See Fig. 1)

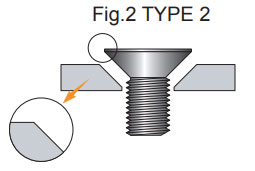

(TYPE 2) Chamfer without a straight section. (See Fig. 2)

The Appearance of TYPE 1 is better than TYPE 2 when put a countersunk screw. TYPE 1 is the standard of CONIC.

-

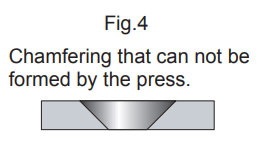

2) Chamfering all from top to bottom of material can not be produced, because contact with the punch and die.

Straight section is required like Fig.4.

- 3)Standard countersunk screw head diameter is twice of the screw size. But some screw head diameter is smaller than the standard. So, be careful when you order.

-

4)If a large amount of chamfer, Raised around the chamfered.

In that case, it can be reduced by increasing the pre-hole diameter

-

1)HALF SHEAR (SHEAR BUTTON)

-

2)EMBOSS (DIMPLE)

-

3)COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

-

4)COUNTERSINK

-

5)COUNTERSINK BURRING

-

6)ONE PITCH THREAD FORM

-

7)BURRING FOR THREAD FORM

-

8)BURRING

-

9)CURLING

-

10)EMBOSS

-

11)CENTER POINT

-

12)KNOCKOUT

-

13)BRIDGE, DOUBLE BRIDGE

-

14)LANCE (Z-BENDING)

-

15)LANCE (L-BENDING)

-

16)LANCE FOR AIR FLOW

-

17)OUVER FOR AIR FLOW

-

18)BEADING

-

19)CARD GUIDE

-

20)BENDING (OFFSET TOOL)

-

21)MARKING (STAMPING)

-

22)MARKING (EMBOSS)

-

23)PROJECTION

-

24)HINGE TOOL

-

25)SPECIAL TOOL USERS MANUAL (AMADA TYPE)

-

26)SPECIAL TOOL USERS MANUAL (MURATA TYPE)

-

27)TOOLING STRUCTURE AND PARTS NAME (AMADA TYPE)