21) MARKING (STAMPING)

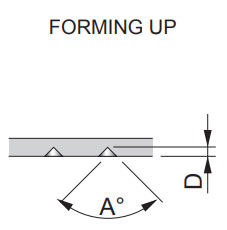

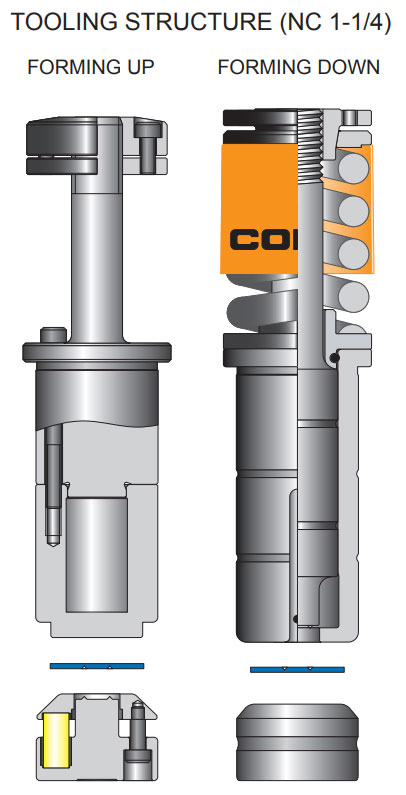

OUTLINE OF FORMING

Forming process of stamping the character or logo etc.

NOTE

- 1)Please indicate the size of character when you order.

- 2)Standard marking angle(A) is 90°.(We can make marking angle 60°, when the character size is small.)

-

3)

The minimum character size that can be formed is as follows.(Height of character)

Number Chinese characters 1mm 3mm -

4)

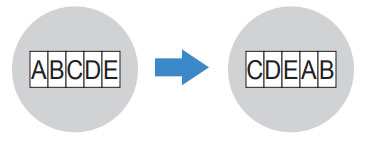

We can also make the insert chip type that can be replaced characters.

-

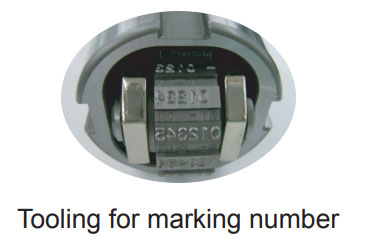

5) "Tooling for marking number" is useful for marking manufacturing number.

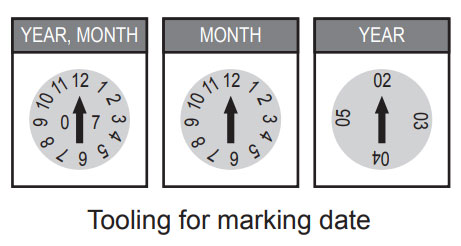

"Tooling for marking date" is useful for marking manufacturing date.

PDF Download

-

1)HALF SHEAR (SHEAR BUTTON)

-

2)EMBOSS (DIMPLE)

-

3)COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

-

4)COUNTERSINK

-

5)COUNTERSINK BURRING

-

6)ONE PITCH THREAD FORM

-

7)BURRING FOR THREAD FORM

-

8)BURRING

-

9)CURLING

-

10)EMBOSS

-

11)CENTER POINT

-

12)KNOCKOUT

-

13)BRIDGE, DOUBLE BRIDGE

-

14)LANCE (Z-BENDING)

-

15)LANCE (L-BENDING)

-

16)LANCE FOR AIR FLOW

-

17)OUVER FOR AIR FLOW

-

18)BEADING

-

19)CARD GUIDE

-

20)BENDING (OFFSET TOOL)

-

21)MARKING (STAMPING)

-

22)MARKING (EMBOSS)

-

23)PROJECTION

-

24)HINGE TOOL

-

25)SPECIAL TOOL USERS MANUAL (AMADA TYPE)

-

26)SPECIAL TOOL USERS MANUAL (MURATA TYPE)

-

27)TOOLING STRUCTURE AND PARTS NAME (AMADA TYPE)