18) BEADING

OUTLINE OF FORMING

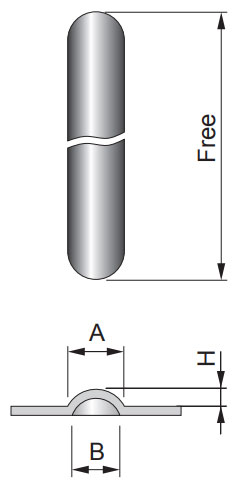

Forming process of embossing that can hit continuously along the sheet.

Used for strengthening, nonslip or decoration.

NOTE

- 1)The height(H) is preferably less than 40% of width(A).

- 2)Please indicate the dimension of A or B, when you order.

-

3)

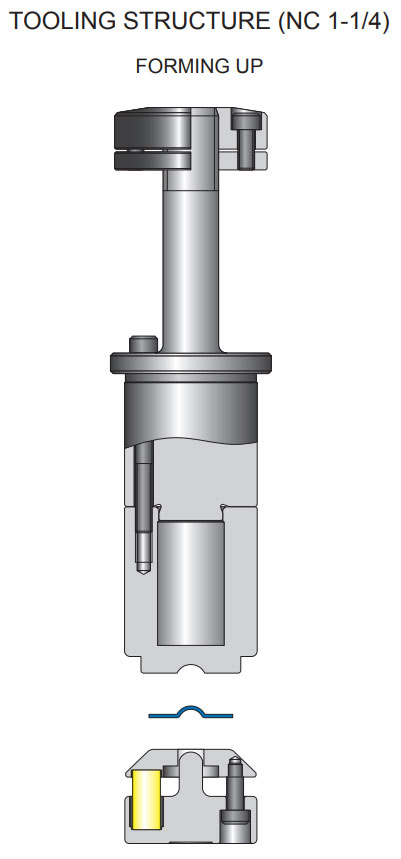

There are the following types of tooling.

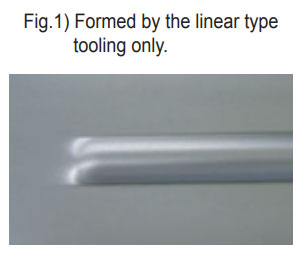

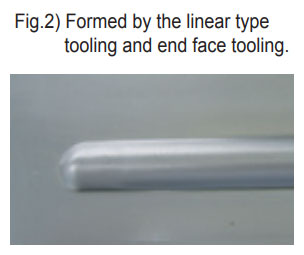

- ①For the linear. (Punching the straight portion)

- ②For the curve portion. (Punching the curved section)

- ③For the end face. (Punching of the end face of beeding)

PDF Download

-

1)HALF SHEAR (SHEAR BUTTON)

-

2)EMBOSS (DIMPLE)

-

3)COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

-

4)COUNTERSINK

-

5)COUNTERSINK BURRING

-

6)ONE PITCH THREAD FORM

-

7)BURRING FOR THREAD FORM

-

8)BURRING

-

9)CURLING

-

10)EMBOSS

-

11)CENTER POINT

-

12)KNOCKOUT

-

13)BRIDGE, DOUBLE BRIDGE

-

14)LANCE (Z-BENDING)

-

15)LANCE (L-BENDING)

-

16)LANCE FOR AIR FLOW

-

17)OUVER FOR AIR FLOW

-

18)BEADING

-

19)CARD GUIDE

-

20)BENDING (OFFSET TOOL)

-

21)MARKING (STAMPING)

-

22)MARKING (EMBOSS)

-

23)PROJECTION

-

24)HINGE TOOL

-

25)SPECIAL TOOL USERS MANUAL (AMADA TYPE)

-

26)SPECIAL TOOL USERS MANUAL (MURATA TYPE)

-

27)TOOLING STRUCTURE AND PARTS NAME (AMADA TYPE)