17) LOUVER FOR AIR FLOW

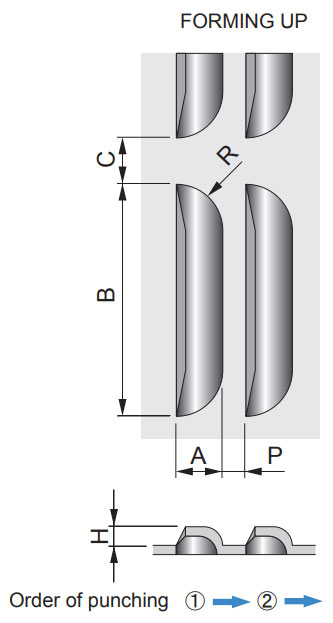

OUTLINE OF FORMING

Forming process of lance to create an opening.

Used to provide air flow or ventilation.

NOTE

-

1) Conditions of punching

Material thickness ≦ 2.3 mm

Width(A) ≧ Height(H) x 2

Height(H) ≦ Material thickness x 4 (Mild steel)Forming pitch P ≧ 5

C ≧ 5 (Material thickness ≦ 1.6 mm

C ≧ 8 (Material thickness > 1.6 mm)

Height(H) ≦ Material thickness x 3.5 (Stainless steel, Aluminum)- ※If the punching conditions are not met, please contact us.

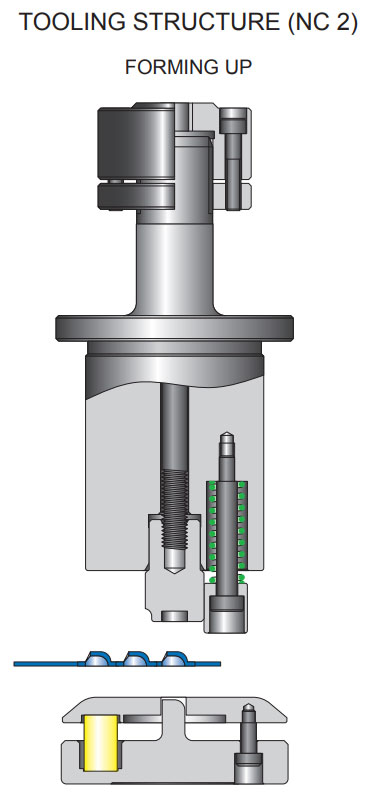

- 2)Upper tool is the punch tip type except for some models.

- 3)Except for some models, the upper tool is a replaceable blade type.

PDF Download

-

1)HALF SHEAR (SHEAR BUTTON)

-

2)EMBOSS (DIMPLE)

-

3)COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

-

4)COUNTERSINK

-

5)COUNTERSINK BURRING

-

6)ONE PITCH THREAD FORM

-

7)BURRING FOR THREAD FORM

-

8)BURRING

-

9)CURLING

-

10)EMBOSS

-

11)CENTER POINT

-

12)KNOCKOUT

-

13)BRIDGE, DOUBLE BRIDGE

-

14)LANCE (Z-BENDING)

-

15)LANCE (L-BENDING)

-

16)LANCE FOR AIR FLOW

-

17)OUVER FOR AIR FLOW

-

18)BEADING

-

19)CARD GUIDE

-

20)BENDING (OFFSET TOOL)

-

21)MARKING (STAMPING)

-

22)MARKING (EMBOSS)

-

23)PROJECTION

-

24)HINGE TOOL

-

25)SPECIAL TOOL USERS MANUAL (AMADA TYPE)

-

26)SPECIAL TOOL USERS MANUAL (MURATA TYPE)

-

27)TOOLING STRUCTURE AND PARTS NAME (AMADA TYPE)