1) HALF SHEAR (SHEAR BUTTON)

OUTLINE OF FORMING

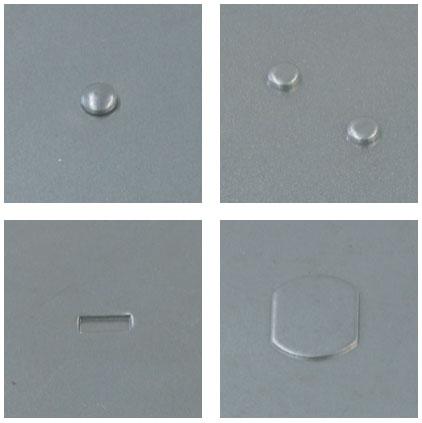

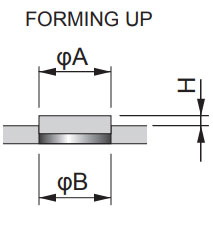

Forming process of pierce half of material thickness.

Used for positioning or stopper.

NOTE

- 1)Please indicate the dimension of A or B, when you order.(You can also have both dimension A and B)

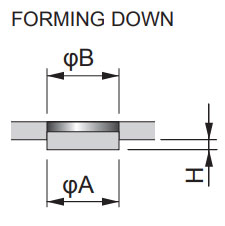

-

2)The height(H) is preferably less than 60% of the material thickness.

In addition, unless otherwise instructed us is about half of the material thickness. - 3)A dimensional tolerance of the dimensions of your instructions unless otherwise is ± 0.02.

Please indicate if you would like other dimensional tolerances. - 4)You can also have the type extrusion upon request.(φA<φB)

- 5)Can be processed special shape or rectangular shape.

-

6)If the shear button is easy to loose, then put chamfering on the corner of tip pin to be hard to come off.

- 7) Even if the thickness change, unnecessary height adjustment tooling can also be produced.

PDF Download

-

1)HALF SHEAR (SHEAR BUTTON)

-

2)EMBOSS (DIMPLE)

-

3)COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

-

4)COUNTERSINK

-

5)COUNTERSINK BURRING

-

6)ONE PITCH THREAD FORM

-

7)BURRING FOR THREAD FORM

-

8)BURRING

-

9)CURLING

-

10)EMBOSS

-

11)CENTER POINT

-

12)KNOCKOUT

-

13)BRIDGE, DOUBLE BRIDGE

-

14)LANCE (Z-BENDING)

-

15)LANCE (L-BENDING)

-

16)LANCE FOR AIR FLOW

-

17)OUVER FOR AIR FLOW

-

18)BEADING

-

19)CARD GUIDE

-

20)BENDING (OFFSET TOOL)

-

21)MARKING (STAMPING)

-

22)MARKING (EMBOSS)

-

23)PROJECTION

-

24)HINGE TOOL

-

25)SPECIAL TOOL USERS MANUAL (AMADA TYPE)

-

26)SPECIAL TOOL USERS MANUAL (MURATA TYPE)

-

27)TOOLING STRUCTURE AND PARTS NAME (AMADA TYPE)