7) BURRING FOR THREAD FORM

OUTLINE OF FORMING

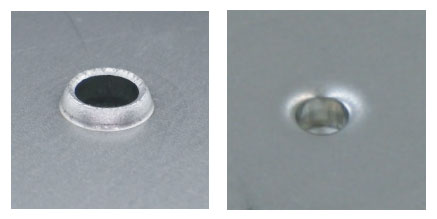

Forming process for making tubes of threading for screw.

Threading for screws and increased bearing area for tubes.

NOTE

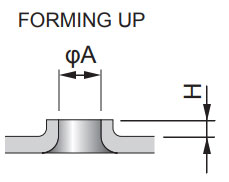

- 1)Height(H) is almost same as material thickness.

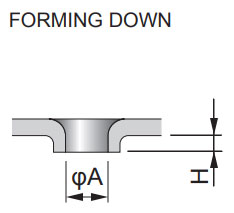

- 2)There are two types of tooling.

- ・One is forming together with pre-piercing at the same time.

- ・And the other is forming after pre-piercing.

-

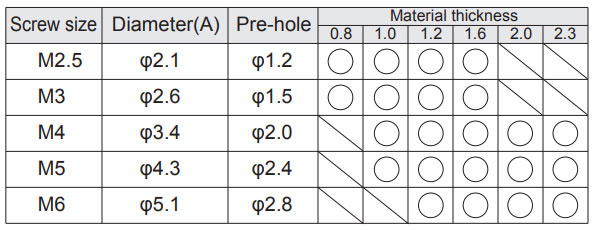

3) Please indicate the screw size or diameter (A),

when you order.

Our standard size is shown in the table below.

- 4)Upward pin of the standard dimensions has "TiN coating process" for better durability.

PDF Download

-

1)HALF SHEAR (SHEAR BUTTON)

-

2)EMBOSS (DIMPLE)

-

3)COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

-

4)COUNTERSINK

-

5)COUNTERSINK BURRING

-

6)ONE PITCH THREAD FORM

-

7)BURRING FOR THREAD FORM

-

8)BURRING

-

9)CURLING

-

10)EMBOSS

-

11)CENTER POINT

-

12)KNOCKOUT

-

13)BRIDGE, DOUBLE BRIDGE

-

14)LANCE (Z-BENDING)

-

15)LANCE (L-BENDING)

-

16)LANCE FOR AIR FLOW

-

17)OUVER FOR AIR FLOW

-

18)BEADING

-

19)CARD GUIDE

-

20)BENDING (OFFSET TOOL)

-

21)MARKING (STAMPING)

-

22)MARKING (EMBOSS)

-

23)PROJECTION

-

24)HINGE TOOL

-

25)SPECIAL TOOL USERS MANUAL (AMADA TYPE)

-

26)SPECIAL TOOL USERS MANUAL (MURATA TYPE)

-

27)TOOLING STRUCTURE AND PARTS NAME (AMADA TYPE)