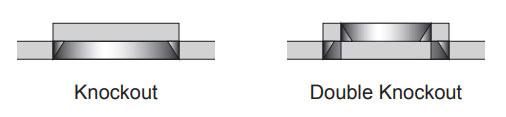

12) KNOCKOUT

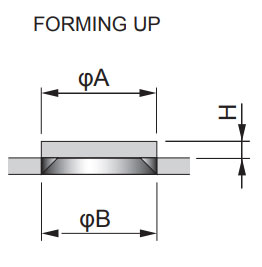

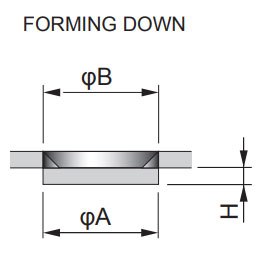

OUTLINE OF FORMING

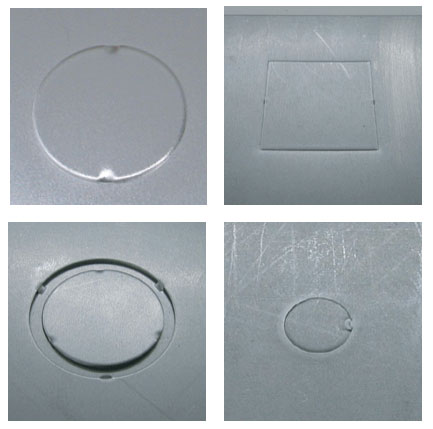

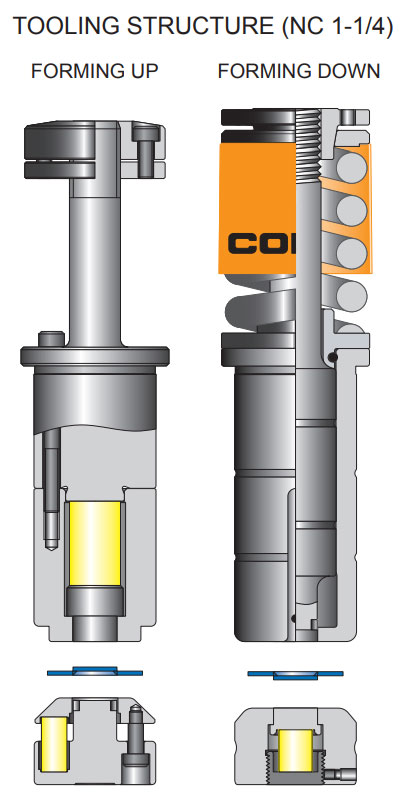

Forming process of piercing a hole and keep the slug on the sheet metal by tabs.

When using a hole, remove the slug using a screwdriver.

NOTE

- 1)Please indicate the dimension of A or B, when you order.

(Indication of the hole diameter(A) is common.) -

2)The height(H) is almost same as the material thickness.

It also may be used in flat that pushed back after the knockout.In this case, please use the flattening tool.

- 3)The number and width of the tab depends on the material,

material thickness and the hole diameter. -

4)We also can produce the "double knockout" that have 2 size of hole diameter.

PDF Download

-

1)HALF SHEAR (SHEAR BUTTON)

-

2)EMBOSS (DIMPLE)

-

3)COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

-

4)COUNTERSINK

-

5)COUNTERSINK BURRING

-

6)ONE PITCH THREAD FORM

-

7)BURRING FOR THREAD FORM

-

8)BURRING

-

9)CURLING

-

10)EMBOSS

-

11)CENTER POINT

-

12)KNOCKOUT

-

13)BRIDGE, DOUBLE BRIDGE

-

14)LANCE (Z-BENDING)

-

15)LANCE (L-BENDING)

-

16)LANCE FOR AIR FLOW

-

17)OUVER FOR AIR FLOW

-

18)BEADING

-

19)CARD GUIDE

-

20)BENDING (OFFSET TOOL)

-

21)MARKING (STAMPING)

-

22)MARKING (EMBOSS)

-

23)PROJECTION

-

24)HINGE TOOL

-

25)SPECIAL TOOL USERS MANUAL (AMADA TYPE)

-

26)SPECIAL TOOL USERS MANUAL (MURATA TYPE)

-

27)TOOLING STRUCTURE AND PARTS NAME (AMADA TYPE)