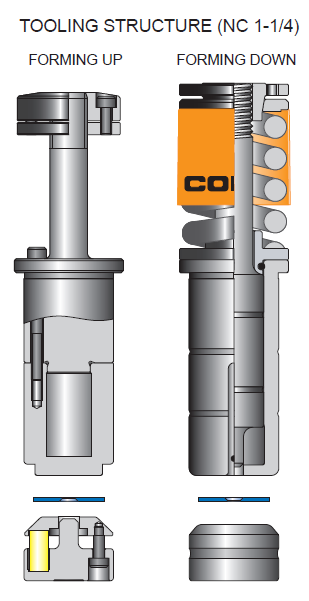

3) COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

OUTLINE OF FORMING

Forming process of making a chamfer to material.

Used for sink a countersunk screw head, make chamfer to a corner after punching, guide of tapping.

NOTE

- 1)

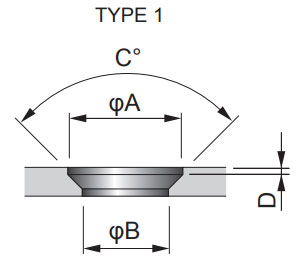

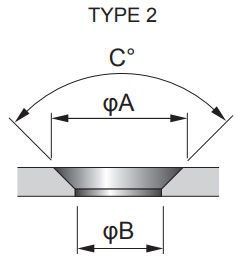

The shape of the chamfer.

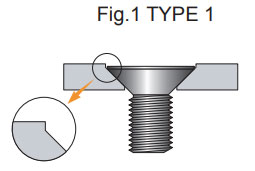

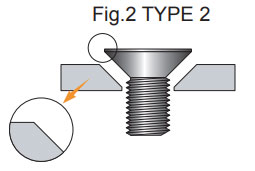

(TYPE 1) Chamfer with a straight section. (See Fig. 1)

(TYPE 2) Chamfer without a straight section. (See Fig. 2)

The Appearance of TYPE 1 is better than TYPE 2 when put a countersunk screw. TYPE 1 is the standard of CONIC.

- 2)

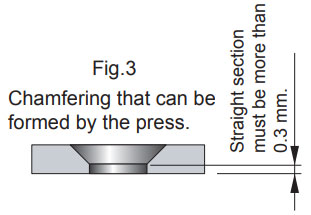

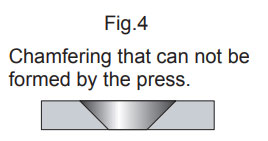

Chamfering all from top to bottom of material can not be produced, because contact with the punch and die.

Straight section is required like Fig.4.

- 3)Standard countersunk screw head diameter is twice of the screw size. But some screw head diameter is smaller than the standard. So, be careful when you order.

- 4)If a large amount of chamfer, Raised around the chamfered.

In that case, it can be reduced by increasing the pre-hole diameter

1)HALF SHEAR (SHEAR BUTTON)

2)EMBOSS (DIMPLE)

3)COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

4)COUNTERSINK

5)COUNTERSINK BURRING

6)ONE PITCH THREAD FORM

7)BURRING FOR THREAD FORM

8)BURRING

9)CURLING

10)EMBOSS

11)CENTER POINT

12)KNOCKOUT

13)BRIDGE, DOUBLE BRIDGE

14)LANCE (Z-BENDING)

15)LANCE (L-BENDING)

16)LANCE FOR AIR FLOW

17)OUVER FOR AIR FLOW

18)BEADING

19)CARD GUIDE

20)BENDING (OFFSET TOOL)

21)MARKING (STAMPING)

22)MARKING (EMBOSS)

23)PROJECTION

24)HINGE TOOL

25)SPECIAL TOOL USERS MANUAL (AMADA TYPE)

26)SPECIAL TOOL USERS MANUAL (MURATA TYPE)

27)TOOLING STRUCTURE AND PARTS NAME (AMADA TYPE)