26) SPECIAL TOOL USERS MANUAL (MURATA TYPE)

To use forming tool safely

Use the tool under appropriate conditions.

Use at other than the specified plate thickness (material) may damage the tool.

Use after adjusting the punch length.

- ・Make sure the difference in shut height for each punch press.

- ・At the time of shipment, Conic set the tool length shorter for safety.

- ・Please adjust the tool length with reference to this manual.

If processing with a multi-process tool;

- ・Pre-hole size

- ・Center position of the machine on the program

Check these out.

Height adjustment method for upward tool

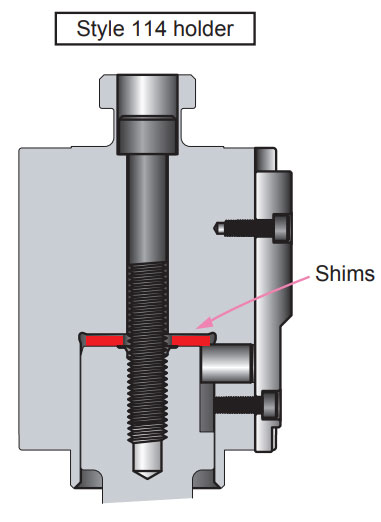

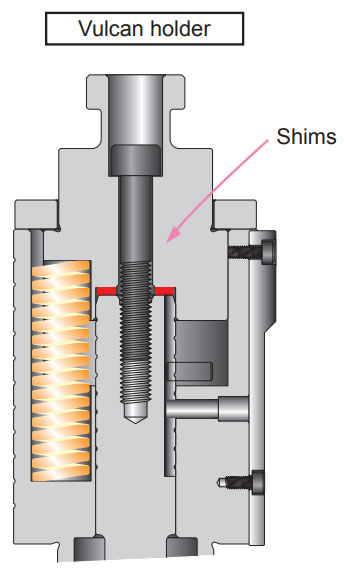

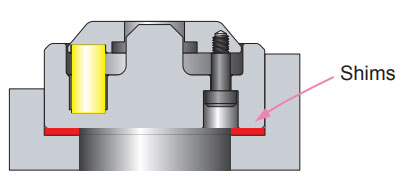

- 1)Adjustment of forming tool is done by shims.

- 2)There are two way to adjust length, one is using punch shims and the other is using die shims.

- 3)First punch without any shims then find the difference and required amount of shims.

Height adjustment method by punch shims

(Insert a shim between the punch and the punch holder.)

Height adjustment method by die shims

(Insert a shim between the die and the die holder.)

Thickness is t=0.4 , 0.5 , 0.6 , 0.7 , 0.8 mm.

It can be adjusted by those combination form 0.4mm to 2.6mm 0.1mm step.

PDF Download

1)HALF SHEAR (SHEAR BUTTON)

2)EMBOSS (DIMPLE)

3)COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

4)COUNTERSINK

5)COUNTERSINK BURRING

6)ONE PITCH THREAD FORM

7)BURRING FOR THREAD FORM

8)BURRING

9)CURLING

10)EMBOSS

11)CENTER POINT

12)KNOCKOUT

13)BRIDGE, DOUBLE BRIDGE

14)LANCE (Z-BENDING)

15)LANCE (L-BENDING)

16)LANCE FOR AIR FLOW

17)OUVER FOR AIR FLOW

18)BEADING

19)CARD GUIDE

20)BENDING (OFFSET TOOL)

21)MARKING (STAMPING)

22)MARKING (EMBOSS)

23)PROJECTION

24)HINGE TOOL

25)SPECIAL TOOL USERS MANUAL (AMADA TYPE)

26)SPECIAL TOOL USERS MANUAL (MURATA TYPE)

27)TOOLING STRUCTURE AND PARTS NAME (AMADA TYPE)