HERRAMIENTAS FORMADO

COUNTERSINK FOR COUNTERSUNK SCREW

COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

COUNTERSINK

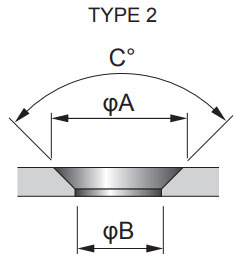

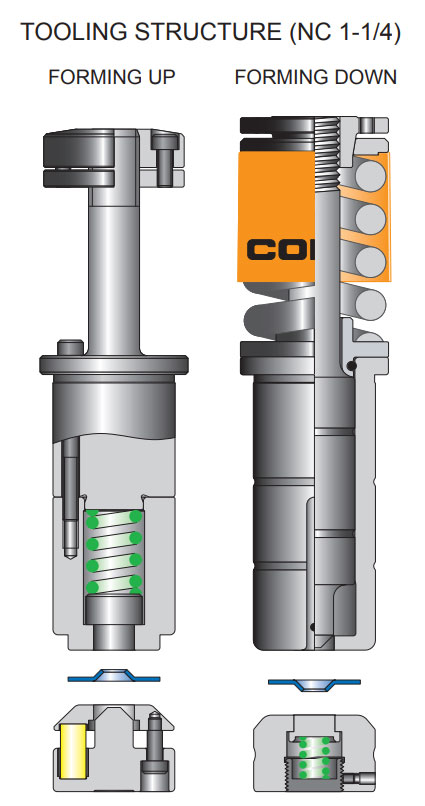

FORMING UP

FORMING DOWN

CHAMFERING (BOTH SIDE)

FORMING SHAPE

FORMING UP & DOWN

USAGE

Locator, decorative pattern of the material or the like.

Forming process of making a chamfer to material.

Used for sink a countersunk screw head, make chamfer to a corner after punching, guide of tapping.

EXAMPLES

This is the example of chamfering 120°on a corner.

It is used to sink a rivet.

The example of making a C chamfering on a rectangle with radius.

The example of making a C chamfering on a Triangle with radius.

COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING)

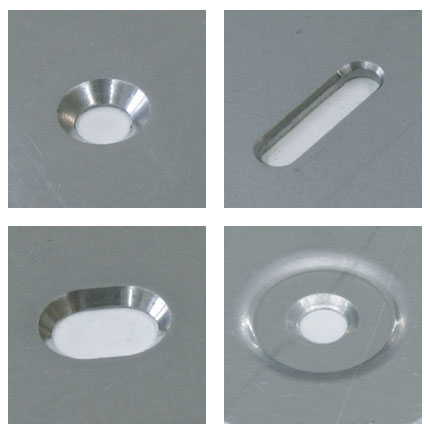

SHAPES OVERVIEW

A workpiece is processed into the hemisphere shape.

NOTE

-

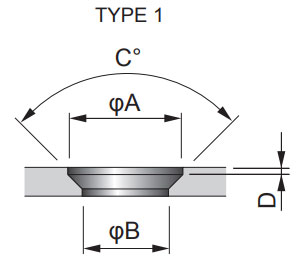

1)The shape of the chamfer.

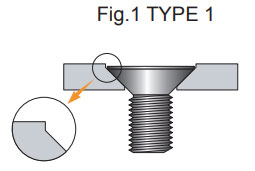

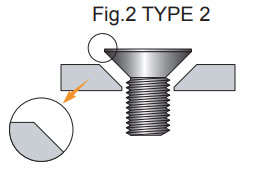

(TYPE 1) Chamfer with a straight section. (See Fig. 1)

(TYPE 2) Chamfer without a straight section. (See Fig. 2)

The Appearance of TYPE 1 is better than TYPE 2 when put a countersunk screw. TYPE 1 is the standard of CONIC.

-

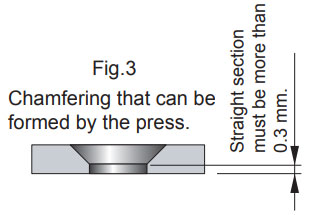

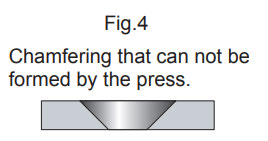

2)Chamfering all from top to bottom of material can not be produced, because contact with the punch and die.

Straight section is required like Fig.4.

- 3)Standard countersunk screw head diameter is twice of the screw size. But some screw head diameter is smaller than the standard. So, be careful when you order.

-

4)If a large amount of chamfer, Raised around the chamfered.

In that case, it can be reduced by increasing the pre-hole diameter