ABOUT US

Okayama Factory Viewing

At Conic, we pursue high quality, short lead times, and competitive pricing through continuous improvement.

Achieving low cost, high quality, and fast delivery is no easy task.

Our quality policy is: “To deliver higher-quality and more affordable products in shortest possible time through company-wide cooperation and continuous improvement.”

We always think from the customer’s perspective and strive to improve both our products and services.

In addition, we promote evolving manufacturing based on our fully in-house production system, supported by a solid foundation of people and processes.

Order

Processing

Order

Processing

Tool Sales Desk

(Ordering, Design, Technical Services)

We reflect customer requirements in our die design.

Once an order is received,

our engineers create detailed manufacturing drawings and issue instructions to the production line.

NC Lathe

Carefully selected Japanese-made special steels.

We carefully select high-grade special steel made in Japan for die manufacturing and perform precision cutting using high-performance machines.

Machining Center

High-Performance Machines for Precision Cutting.

We perform cutting processes such as key grooves and square-shaped punches with high precision.

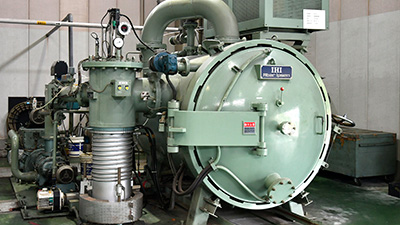

Heat Treatment

Breathing Life into Every Die.

We breathe life into our dies through heat treatment.

With our fully in-house processing system for punches and dies, we ensure consistent high quality without variation.

Cylindrical & Surface Grinding

Pursuing Absolute Precision.

In a temperature-controlled facility, we finish dies with micron-level precision.

Electrical Discharge Machining (EDM)

Leveraging our expertise in special die manufacturing

For complex or custom-shaped dies, we use EDM to achieve the desired geometry.

Wire Cut

High quality and short lead times through dedicated machinery.

In our temperature-controlled room, automated lines produce high-precision dies with short lead times.

Product Inspection (3D Measurement / Image Measurement)

A Rigorous Inspection System.

Certified inspectors conduct final inspections of completed dies and authorize shipment.

Punching Test

Final Performance Testing.

For forming dies, we perform actual test punching to confirm that the final product matches the ordered specifications.

Shipping & Delivery

Shipping & Delivery

Shipping & Delivery

Choosing the Fastest, Most Reliable Delivery.

We select the fastest and most suitable delivery method to ship nationwide, ensuring prompt arrival at our customers’ locations.